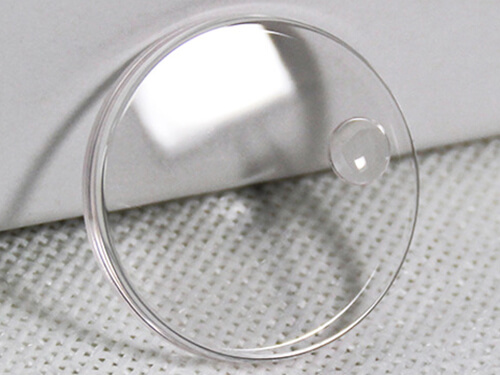

Custom Anti-Reflection (AR) Glass Service

High-quality custom Anti-Reflection (AR) Glass parts supplier at competitive prices.

Contact us now to request a quick quote.

What is Anti-Reflection (AR) Glass?

Anti-reflection (AR) glass is a type of glass that has been treated with a thin layer of coating to reduce the amount of reflection that occurs on its surface. The coating is typically made of a material with a low refractive index, such as magnesium fluoride, which helps to cancel out the reflections that occur when light passes through the glass.

The use of AR glass is particularly important in applications where maximum light transmission and minimum reflection are required, such as in optical lenses, camera lenses, eyeglasses, and electronic displays. By reducing the amount of reflection that occurs on the surface of the glass, AR coatings can improve the clarity, contrast, and overall visual quality of the image.

AR glass is also known for its durability and scratch resistance, making it an ideal choice for applications that require a high degree of wear and tear resistance. It can be used in a variety of settings, including residential and commercial buildings, medical and scientific equipment, and consumer electronics.

What are the properties of anti-reflection (AR) glass?

Anti-reflection (AR) glass has several key properties that make it useful in a wide range of applications:

Low reflectance

AR glass has a thin coating that reduces the amount of light that is reflected off the surface of the glass. This results in higher light transmission, improved clarity, and reduced glare.

High transparency

The thin AR coating on the glass is designed to be as transparent as possible, so it does not significantly affect the color or brightness of the light passing through it.

Abrasion resistance

The AR coating is typically hard and durable, which makes it resistant to scratches, abrasion, and other types of damage.

Chemical resistance

AR glass is resistant to many types of chemicals, making it suitable for use in harsh environments.

Long-lasting

With proper care, AR glass can maintain its anti-reflective properties for many years.

Types of anti-reflection (AR) glass?

There are several types of anti-reflection (AR) glass, each with its own specific properties and applications:

Single-layer AR coatings

This is the simplest type of AR glass, which consists of a single layer of coating applied to the surface of the glass. This type of coating reduces the amount of reflection and increases light transmission. However, it is not as effective as more advanced types of AR coatings.

Multilayer AR coatings

This type of AR glass consists of multiple layers of coating that are designed to cancel out reflections at different wavelengths of light. The result is a highly effective AR coating that can achieve very low levels of reflection.

Broadband AR coatings

This type of AR glass is designed to reduce reflections over a broad range of wavelengths of light. This makes it suitable for applications where a wide spectrum of light is used, such as in spectroscopy or microscopy.

Polarizing AR coatings

This type of AR glass is designed to reduce reflections while also polarizing light. This makes it useful in applications such as LCD displays and other electronic devices.

Hard-coated AR glass

This type of AR glass is treated with a hard, scratch-resistant coating that improves its durability and longevity. This makes it useful in applications where the glass is subject to wear and tear.

Applications of anti-reflection (AR) glass cutting service?

Custom anti-reflection (AR) glass panels, sight windows, and lens cutting services have a wide range of applications in various industries. Some common applications include:

Optical lenses

AR glass is commonly used in optical lenses for cameras, telescopes, microscopes, and other imaging devices. The reduced reflection and increased light transmission improve image quality and clarity.

Medical equipment

AR glass is used in medical devices such as endoscopes, microscopes, and surgical loupes to improve visibility and accuracy.

Aerospace and defense

AR glass is used in cockpit windows and aircraft windshields to improve visibility and reduce glare.

Industrial applications

AR glass is used in sight windows for industrial equipment, such as furnaces, reactors, and pressure vessels, to allow visual inspection of processes while reducing reflections and glare.

Lighting

AR glass can be used in light fixtures to reduce glare and improve light transmission.

Consumer electronics

AR glass is used in electronic displays, such as smartphones, tablets, and laptops, to reduce reflections and improve visibility in bright environments.

Advantages of anti-reflection (AR) glass custom laser cut parts?

Anti-reflection (AR) glass provides several advantages over standard glass:

Improved optical performance

AR glass has a thin coating that reduces the amount of light that is reflected off the surface of the glass, resulting in higher light transmission, improved clarity, and reduced glare.

Better visibility

AR glass reduces glare and reflections, making it easier to see through the glass, even in bright or low-light environments.

Versatility

AR glass can be used in a wide range of applications, including consumer electronics, architectural applications, medical equipment, aerospace and defense, and industrial applications.

Energy efficiency

AR glass can help to improve energy efficiency by reducing the amount of heat that is absorbed or reflected by the glass.

Aesthetically pleasing

AR glass has a clean, polished appearance that enhances the visual appeal of products and applications. efficiency.

Disadvantages of anti-reflection (AR) glass?

While anti-reflection (AR) glass provides several advantages over standard glass, there are also some potential disadvantages to consider:

Cost

AR glass can be more expensive than standard glass due to the additional manufacturing processes involved in producing the anti-reflective coating.

Fragility

The anti-reflective coating on AR glass can be fragile, making it more susceptible to damage if not handled carefully.

Cleaning

AR glass requires more careful cleaning than standard glass, as any residue or dirt left on the surface can affect the anti-reflective properties.

Limited effectiveness

While AR glass is effective at reducing reflections and glare, it may not eliminate them entirely in certain lighting conditions or from certain angles.

Durability

The anti-reflective coating on AR glass can degrade over time, especially if exposed to harsh environments, such as high temperatures or humidity.

Manufacturing limitations

Some types of AR glass coatings may have limitations in terms of the size or shape of the glass that can be coated.

Get Your Custom anti-reflection (AR) glass Parts Into Production Today

Want to save time and money on your anti-reflection (AR) glass parts project? Contact us now. Our factory provides high-quality precision custom anti-reflection (AR) glass products at very competitive prices and fast production times. We support free sample service.