Beveling Service

Precision custom OEM glass & sapphire glass service factory at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass beveling service?

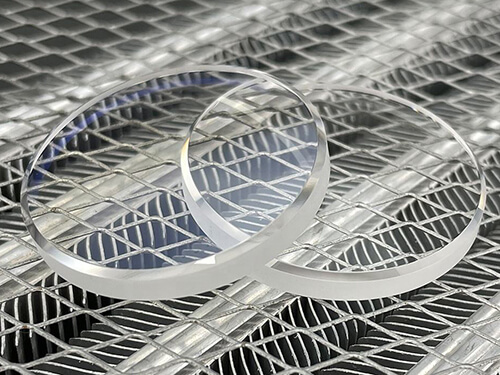

Glass beveling service refers to a process in which the edges of a glass pane are cut and shaped to form a beveled edge. Beveling involves removing a portion of the glass along the edges at a specific angle, typically creating a sloping or angled surface. This process gives the glass a decorative and sophisticated look, adding a touch of elegance to mirrors, tabletops, windows, and other glass surfaces.

During the beveling process, specialized machinery and tools are used to grind and polish the edges of the glass at a precise angle. The angle of the bevel can vary depending on the desired effect or the specific design requirements. Common bevel angles range from 10 to 45 degrees.

HY factory specializes in providing custom beveling service or glass parts and sapphire parts. Our factory produces premium glass and sapphire components at factory-direct prices.

Contact us to get a free quote for your custom glass & sapphire glass parts.

What are the properties of glass & sapphire glass beveling?

Safety

Beveling glass & sapphire glass edges reduces the risk of injuries from sharp edges. By removing the sharp corners and creating a sloping or angled surface, the potential for accidental cuts or scrapes is minimized. This makes beveled glass a safer option, especially in applications where people are likely to come into contact with the glass & sapphire glass, such as tabletops or shower doors.

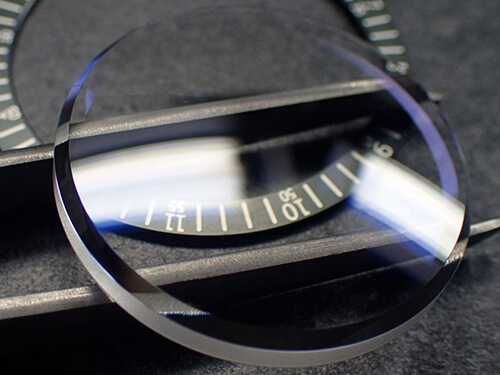

Light Reflection

The angled surfaces of beveled glass & sapphire glass reflect and refract light, creating interesting patterns and enhancing the play of light. This property can be particularly striking when the glass & sapphire glass is exposed to natural or artificial light sources, adding a dynamic element to the visual experience.

Versatility

Beveled glass & sapphire glass can be used in various applications, from decorative pieces such as mirrors and picture frames to functional elements like windows, doors, and tabletops. Its versatility allows it to complement different architectural and design styles, making it a popular choice in both residential and commercial settings.

Durability

While the beveling process removes a portion of the glass & sapphire glass, it does not significantly affect the overall strength and durability of the glass & sapphire glass pane. Beveled glass & sapphire glass retain the inherent strength and resilience, making it suitable for applications that require robust and long-lasting materials.

Customization

Glass & sapphire glass beveling can be customized to meet specific design requirements. The angle of the bevel, the width of the beveled edge, and the overall shape can be tailored to suit individual preferences and project needs. This allows for a high degree of customization and creativity when incorporating beveled glass & sapphire glass into architectural or decorative designs.

Types of glass & sapphire glass beveling?

Glass & sapphire glass beveling is a process that involves cutting and shaping the edges of a glass & sapphire glass pane to create a decorative or functional beveled edge. There are several types of glass & sapphire glass beveling techniques commonly used:

Straight-Line Beveling

This is the most basic form of glass & sapphire glass beveling. It involves creating a straight beveled edge by grinding the glass & sapphire glass at a specific angle using a beveling machine.

Pencil Beveling

In pencil beveling, the edge of the glass & sapphire glass is ground to form a narrow, rounded bevel resembling a pencil. This type of bevel is often used for decorative purposes and can add an elegant touch to glass & sapphire glass edges.

Flat Beveling

Flat beveling refers to the process of creating a flat, wide beveled edge on the glass & sapphire glass. It involves grinding the edge at a specific angle to achieve the desired width and finish.

Triple Beveling

Triple beveling involves grinding the glass & sapphire glass edge at three different angles to create a layered effect. This technique adds depth and complexity to the beveled edge, making it more visually appealing.

Cluster Beveling

Cluster beveling is a more intricate technique that involves creating multiple beveled edges in a clustered or overlapping pattern.

Convex and Concave Beveling

Convex beveling involves shaping the glass & sapphire glass edge to create a curved, outward-facing bevel. Conversely, concave beveling involves creating a curved, inward-facing bevel.

Mitre Beveling

In mitre beveling, the glass & sapphire glass edges are beveled at a specific angle and then joined together at the corners to form a seamless joint.

What are the benefits of glass & sapphire glass beveling?

Safety

Beveled edges are smoother and safer compared to sharp, untreated edges. The grinding and polishing process of glass & sapphire glass beveling removes the sharpness and reduces the risk of accidental cuts or injuries.

Improved Durability

Glass beveling strengthens the edges of the glass & sapphire glass by removing any potential weak points or stress concentrations. This reduces the chances of chips, cracks, or breakages along the edges, resulting in improved durability and longevity of the glass & sapphire glass.

Versatility

Glass & sapphire glass beveling can be applied to various thicknesses and types of glass & sapphire glass. This versatility allows for a wide range of design possibilities and applications.

Decorative Appeal

Glass & sapphire glass beveling enhances the appearance of glass by adding an elegant and sophisticated touch. The beveled edges catch and reflect light, creating a sparkling effect that adds depth and visual interest to the glass & sapphire glass surface.

Light Manipulation

Beveled edges refract and reflect light, creating unique light patterns and enhancing the overall lighting effects in a space. The beveled angles can direct and disperse light, creating a play of shadows and highlights.

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & Sapphire Glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.