Custom High Borosilicate Glass Service

High-quality custom High Borosilicate Glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is High Borosilicate Glass ?

High borosilicate glass is a type of glass that contains boron trioxide as a major component. It is known for its high resistance to thermal shock, chemical corrosion, and mechanical impact. Borosilicate glass is commonly used for laboratory glassware, cookware, lighting products, and various industrial applications.

One of the key properties of borosilicate glass is its low coefficient of thermal expansion, which means it can resist sudden changes in temperature without cracking or shattering. This makes it an ideal material for products that require high-temperature resistance, such as baking dishes, laboratory glassware, and high-performance lighting products.

Borosilicate glass is also highly resistant to chemical corrosion, which makes it suitable for use with harsh chemicals and acids. It is often used for chemical storage containers, laboratory glassware, and industrial equipment that handle corrosive substances.

Borosilicate glass is a durable and versatile material that is valued for its thermal shock resistance, chemical resistance, and durability.

What are the properties of borosilicate glass?

Chemical Properties

Resistant to chemical corrosion, making it suitable for use with harsh chemicals and acids. Highly inert, meaning it does not react with most substances.

Electrical Properties

High dielectric strength, making it useful for electrical insulators. Low electrical conductivity, making it suitable for applications where electrical insulation is required.

Thermal Properties

Low coefficient of thermal expansion, meaning it can resist sudden changes in temperature without cracking or shattering. High resistance to thermal shock, making it suitable for use with high-temperature applications.

Mechanical Properties

High strength and durability, making it resistant to mechanical impact and deformation. Low coefficient of friction, meaning it has good slip and wear resistance.

Physical Properties

Relatively low density, making it lightweight. Non-porous surface, making it easy to clean and sterilize. Does not absorb moisture or odors, making it suitable for food and beverage containers.

Optical Properties

High transparency, making it suitable for use in optical applications such as lenses and prisms. Low dispersion, meaning it can refract light without causing chromatic aberration.

Types of borosilicate glass?

There are several types of borosilicate glass, each with different properties and characteristics. Here are some of the common types of borosilicate glass:

Type I borosilicate glass

Also known as Pyrex, this is the most common type of borosilicate glass. It is composed of silica (SiO2), boron oxide (B2O3), and aluminum oxide (Al2O3) and is known for its high resistance to thermal shock and chemical corrosion.

Type II borosilicate glass

This type of borosilicate glass contains less boron oxide than Type I glass, which makes it less resistant to thermal shock but more resistant to chemical corrosion.

Type III borosilicate glass

This type of borosilicate glass contains less boron oxide and aluminum oxide than Type II glass, which makes it less expensive and easier to melt.

High-index borosilicate glass

This type of borosilicate glass contains a higher percentage of boron oxide and has a higher refractive index, making it useful for optical applications such as lenses and prisms.

Aluminosilicate glass

This type of borosilicate glass contains a higher percentage of aluminum oxide and is known for its high mechanical strength and resistance to thermal shock.

Applications of Borosilicate glass cutting service?

Borosilicate glass sheet cutting service is versatile and can be used for a wide range of applications where high thermal shock resistance, chemical resistance, and optical clarity are required.

Industrial equipment

Borosilicate glass sheets can be cut and shaped to create sight glass windows for industrial equipment, such as boilers, reactors, and tanks. These windows allow operators to observe the processes inside the equipment without having to open it up.

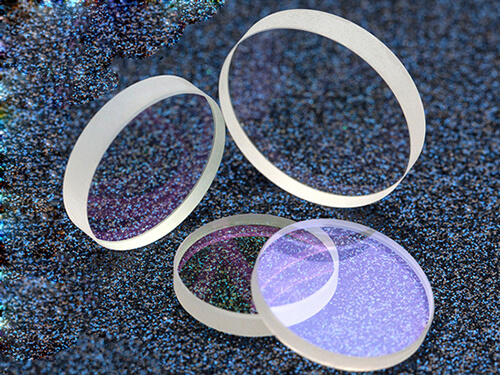

Optical lenses and mirrors

Borosilicate glass sheets can be cut and polished to create high-quality optical lenses and mirrors for use in cameras, telescopes, and other optical instruments. The high transparency and low dispersion of borosilicate glass make it ideal for these applications.

Lighting

Borosilicate glass sheet can be used to create high-temperature lamp shades and covers, as well as for LED lighting applications. The high thermal shock resistance of borosilicate glass makes it ideal for use in these applications.

Laboratory glassware

Borosilicate glass sheets can be cut to precise dimensions to create laboratory glassware such as beakers, flasks, and test tubes. The high thermal shock resistance and chemical resistance of borosilicate glass make it ideal for use in laboratory applications.

Display cases

Borosilicate glass sheets can be used to create display cases for museums, galleries, and retail stores. The high transparency and low distortion of borosilicate glass make it ideal for displaying artifacts and products.

What advantages of custom Borosilicate glass parts?

Borosilicate glass is a type of glass that contains boron trioxide, which gives it unique properties that make it advantageous for various applications. Here are some advantages of borosilicate glass:

Thermal shock resistance

Borosilicate glass has a low coefficient of thermal expansion, which means it can withstand sudden temperature changes without breaking. This makes it ideal for laboratory and industrial applications where rapid heating or cooling is required.

High chemical resistance

Borosilicate glass is highly resistant to chemicals, including strong acids, bases, and organic solvents. This makes it ideal for use in laboratory equipment, such as beakers, test tubes, and flasks.

Durability

Borosilicate glass is highly durable and can withstand physical stress and mechanical impact without breaking. This makes it ideal for use in high-stress applications, such as in the construction of high-pressure gauge glasses.

Clarity

Borosilicate glass is highly transparent, with low levels of distortion and coloration. This makes it ideal for use in optical applications, such as lenses, prisms, and mirrors.

The unique properties of borosilicate glass make it a highly versatile and useful material for a wide range of applications, including laboratory equipment, optical components, and consumer goods.

What're disadvantages of borosilicate glass?

While borosilicate glass has many advantages, there are also some potential disadvantages to consider:

Cost

Borosilicate glass is generally more expensive than other types of glass. This is because it requires specialized manufacturing processes and raw materials, such as boron trioxide.

Brittleness

While borosilicate glass is more durable than other types of glass, it is still relatively brittle and can break or chip if dropped or subjected to sudden impacts.

Weight

Borosilicate glass is denser than other types of glass, which means it can be heavier and bulkier. This can make it less practical for certain applications where weight is a concern.

Processing difficulty

Borosilicate glass is more difficult to shape and process than other types of glass, which can make it more challenging to produce certain products.

Limited availability

Because of its specialized manufacturing processes, borosilicate glass may not be as widely available as other types of glass, which can make it more difficult to source in some regions.

While borosilicate glass has many advantages, it may not be the best choice for every application due to its higher cost, weight, and processing difficulty.

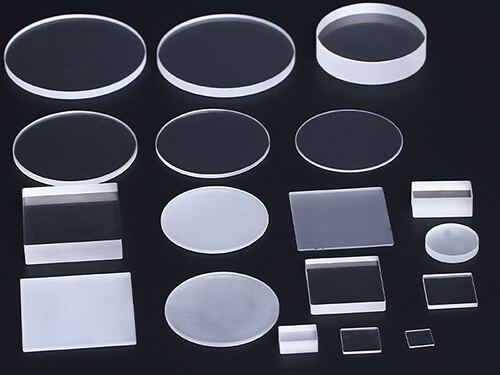

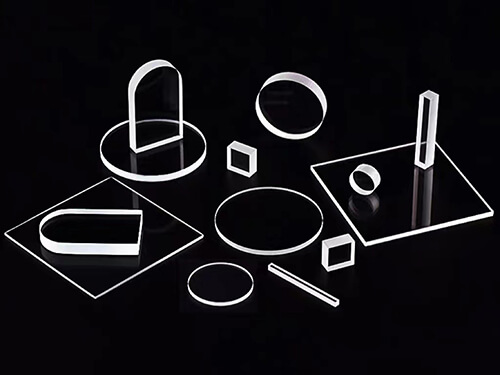

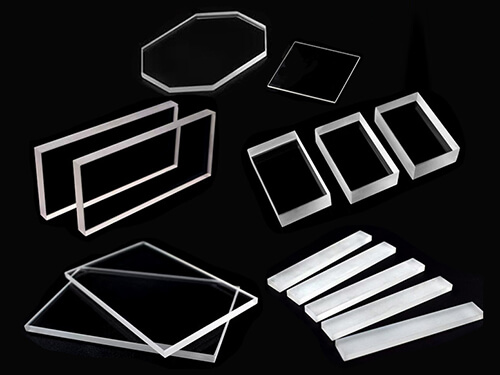

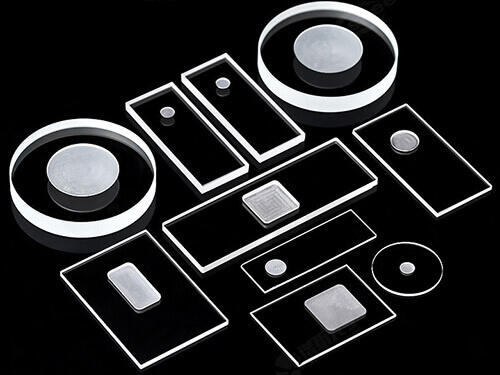

Custom borosilicate glass Parts We Can Manufacture

- Frosted Glass Lens

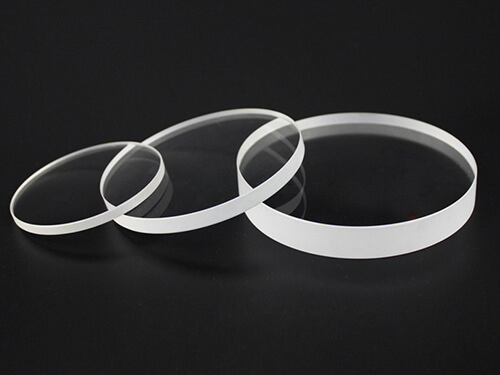

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

What's custom borosilicate glass laser cutting service?

Laser cutting custom borosilicate glass service is a process of cutting borosilicate glass using a high-powered laser beam.

Borosilicate glass is a type of glass that is known for its high resistance to thermal shock, making it ideal for applications that require resistance to high temperatures and thermal stresses.

Laser cutting is a precise and accurate way to cut borosilicate glass into customized shapes and sizes.

In this process, a laser beam is focused onto the surface of the borosilicate glass, which causes the material to heat up and melt, resulting in a precise cut.

The process can be used to cut complex shapes and intricate designs with a high degree of accuracy, which makes it a popular choice for creating custom borosilicate glass products.

Laser-cutting custom borosilicate glass can be used in a variety of applications, including scientific instruments, laboratory equipment, industrial machinery, and consumer products.

The process can produce high-quality, precise cuts with minimal waste, which makes it an efficient and cost-effective option for creating custom glass products.

How to ensure the precision of the custom laser cutting borosilicate glass parts?

There are several ways to ensure the precision of borosilicate glass sheets cut to size service:

Accurate measurements:

Accurate measurements of the glass sheets are critical to ensure that the final product is cut to the desired size. To achieve this, precise measuring tools should be used, and measurements should be taken multiple times to ensure consistency.

Accurate Measurements:

It's essential to have accurate measurements of the glass sheets to ensure precision. This can be achieved through precise measurement techniques such as digital calipers or laser measuring devices.

High-Quality Cutting Equipment:

Using high-quality cutting equipment is critical to achieving precise cuts. Laser-cutting machines are preferred for borosilicate glass as they offer high accuracy and precision.

Experienced Operators:

Experienced operators who have a thorough understanding of the material and the cutting process can ensure the precision of the cut. They can make adjustments to the machine settings and cutting parameters to achieve the desired results.

Quality Control Checks:

Regular quality control checks during the cutting process can help identify any deviations from the required dimensions and ensure that the final product meets the specifications

Proper Handling and Packaging:

Proper handling and packaging of the cut borosilicate glass sheets can prevent damage and ensure that the product remains in its original dimensions.

Precision in borosilicate glass sheets cut-to-size service can be achieved through a combination of accurate measurements, high-quality cutting equipment, experienced operators, quality control checks, and proper handling and packaging.

What's custom borosilicate glass CNC machining fabricate service?

Custom borosilicate glass CNC machining fabricate service is a process of using computer-controlled machines to remove material from a borosilicate glass block to create a customized part or product.

CNC stands for “Computer Numerical Control,” which means that the machine is controlled by a computer program that directs the movements of the cutting tool.

Borosilicate glass is a type of glass that is known for its high resistance to thermal shock, making it ideal for applications that require resistance to high temperatures and thermal stresses.

CNC machining is a precise and accurate way to shape borosilicate glass into customized shapes and sizes.

In this process, a computer-aided design (CAD) program is used to create a 3D model of the part or product to be fabricated. The program then generates a set of instructions that are sent to the CNC machine.

The machine uses cutting tools, such as drills and mills, to remove material from the borosilicate glass block, following the instructions from the program to create the desired shape.

Custom borosilicate glass CNC machining fabricate service can be used in a variety of applications, including scientific instruments, laboratory equipment, industrial machinery, and consumer products.

The process can produce high-quality, precise parts with complex shapes and intricate designs, making it a popular choice for creating custom borosilicate glass products.

What are the coating types of borosilicate glass parts?

There are several coating types that can be applied to custom borosilicate glass lenses depending on the specific requirements of the application. Some of the common coating types are:

Anti-reflective (AR) coating

This type of coating is designed to increase the scratch resistance of the lens surface. Hard coatings are often used in applications where the lens may be exposed to abrasive or harsh environments.

Hard coating

This type of coating is designed to increase the scratch resistance of the lens surface. Hard coatings are often used in applications where the lens may be exposed to abrasive or harsh environments.

Hydrophobic coating

This coating is designed to repel water and other liquids from the lens surface, thereby reducing the formation of water droplets or stains. Hydrophobic coatings are often used in outdoor or high humidity environments.

Anti-fog coating

This type of coating is designed to prevent fogging on the lens surface, thereby improving visibility in humid environments. Anti-fog coatings are often used in medical or industrial applications where clear vision is essential.

UV-protective coating

This coating is designed to block harmful UV radiation from the sun, which can cause eye damage and other health problems. UV-protective coatings are often used in sunglasses, safety glasses, and other outdoor eyewear.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom borosilicate glass Parts Into Production Today

Want to save time and money on your borosilicate glass parts project? Contact us now. Our factory provides high-quality precision custom borosilicate glass products at very competitive prices and fast production times. We support free sample service.