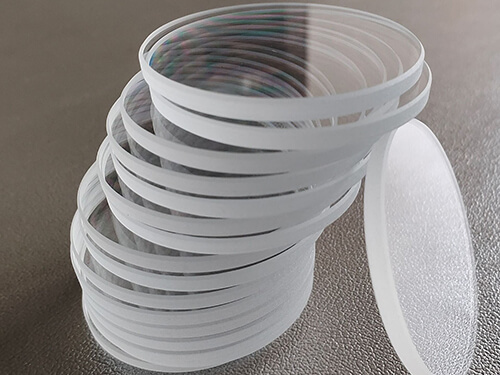

Chamfer Service

High-quality custom glass & sapphire glass chamfer service manufacturer at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass chamfer service?

Glass & sapphire glass chamfer service refers to a process in which the edges of a glass & sapphire glass panel or piece are shaped into chamfers. A chamfer is a beveled edge that is cut or ground at an angle, typically a 45-degree angle, to create a smooth, polished, and aesthetically pleasing finish.

Glass & sapphire glass chamfering is commonly used in various applications where glass & sapphire glass edges need to be smoothed and rounded off. This process helps to enhance the safety and durability of the glass by reducing the risk of sharp edges that can cause injury and damage.

The chamfering process is typically carried out using specialized machinery, such as glass & sapphire glass grinding or bevelling machines. The glass & sapphire glass panel is positioned and secured in the machine, and the edges are carefully shaped and polished to create the desired chamfer profile.

What are the properties of glass & sapphire glass chamfer?

The properties of glass & sapphire glass chamfer depend on various factors, including the angle of the chamfer, the thickness of the glass & sapphire glass, and the quality of the chamfering process. Here are some general properties associated with glass & sapphire glass chamfer:

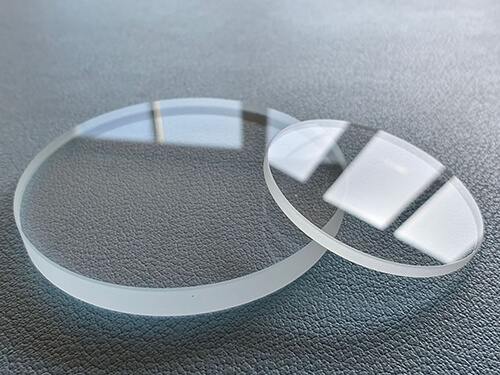

Smoothness

Chamfering creates a smooth and polished edge on the glass & sapphire glass, eliminating sharp edges and rough surfaces. This enhances both the aesthetic appeal and the safety of the glass & sapphire glass.

Versatility

Glass CNC laser cutting is versatile and can be used with various types of glass, including float glass, tempered glass, laminated glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Safety

Chamfered glass & sapphire glass edges are safer than sharp edges as they reduce the risk of cuts and injuries. The beveled angle of the chamfer helps distribute stress more evenly, minimizing the likelihood of fractures or breakages.

Durability

By chamfering the edges of the glass & sapphire glass, the vulnerable corners are removed or rounded off, reducing the likelihood of chipping or cracking. This improves the overall durability and longevity of the glass & sapphire glass.

Types of glass & sapphire glass chamfer?

There are several types of glass & sapphire glass chamfer that can be applied to achieve different aesthetic and functional effects. Here are some common types of glass & sapphire glass chamfer:

Standard Chamfer

This is the most basic type of chamfer, characterized by a straight beveled edge at a fixed angle, typically 45 degrees.

Pencil Chamfer

This chamfer type features a smaller bevel angle, usually around 20 to 30 degrees, resulting in a thinner and more delicate edge.

Deep Chamfer

Deep chamfer refers to a chamfer with a greater bevel angle, typically exceeding 45 degrees. It creates a more pronounced and bold edge, adding a distinct design element to the glass & sapphire glass.

Rounded Chamfer

Instead of a straight beveled edge, the rounded chamfer features a curved profile, giving the glass & sapphire glass a softer and smoother appearance. This type of chamfer is often used for safety purposes, as it reduces the risk of injury from sharp corners.

Decorative Chamfer

Decorative chamfers involve creating unique patterns, shapes, or designs on the glass edge. This can include V-shaped chamfers, stepped chamfers, or customized chamfer profiles that enhance the visual appeal of the glass & sapphire glass.

Variable Chamfer

Variable chamfer involves applying chamfers with different angles or sizes on different edges of the glass & sapphire glass panel or piece. This technique is often used to create asymmetrical designs or to complement specific architectural or design requirements.

What are the benefits of glass & Sapphire glass CNC laser cutting?

Safety

Chamfering glass & sapphire glass edges reduce the risk of injury. Sharp edges can be hazardous, especially in environments where there is a higher risk of accidental contact. Chamfering eliminates sharp corners, making the glass & sapphire glass safer to handle and reducing the potential for cuts or injuries.

Durability

Chamfering reinforces the edges of the glass & sapphire glass, reducing the likelihood of chipping or cracking. The beveled edge disperses stress more evenly along the edge, enhancing the structural integrity of the glass & sapphire glass. This increases its durability and helps to prolong its lifespan.

Improved Functionality

Chamfering can improve the functionality of glass & sapphire glass in various applications. For example, chamfered glass & sapphire glass edges are more comfortable to handle, making them suitable for tabletops or handrails. They can also reduce the risk of damage to adjacent materials or surfaces when glass & sapphire glass is installed in design projects.

Customization

Glass & sapphire glass chamfering allows for customization and design flexibility. Different chamfer angles, sizes, or decorative patterns can be applied to achieve specific design requirements or match the overall aesthetic theme of a project.

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & Sapphire Glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.