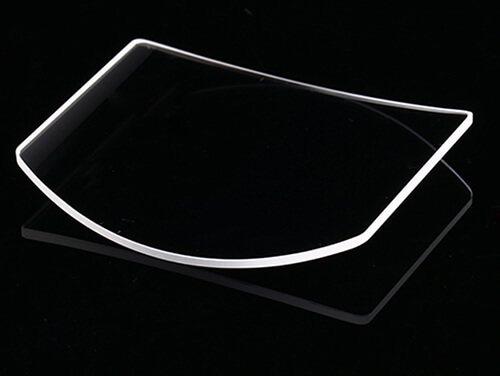

Clear Float Glass (Soda Lime) Service

High-quality precision clear float glass ( (Soda Lime)) supplier with competitive prices.

Contact us now to request a quick quote or get a free sample

What is clear float glass (soda lime glass)?

Clear float glass, also known as soda lime glass, is a type of flat glass that is commonly used in construction, automotive, and other industries. It is made by melting a mixture of silica sand, soda ash, and limestone in a furnace until it becomes molten. The molten glass is then poured onto a bed of molten tin, which forms a flat and smooth surface. The glass is allowed to cool and solidify on the tin, which results in a uniform thickness and a flat and smooth surface.

Soda lime glass is named after the two main ingredients used in its production: soda (sodium carbonate) and lime (calcium oxide). The soda is added to the mixture to reduce the melting temperature of the silica sand, while the lime helps to stabilize the mixture and improve its workability.

Clear float glass has a high level of transparency and clarity, which makes it ideal for applications where optical quality is essential, such as windows, mirrors, and display screens. It also has excellent thermal insulation properties and can be coated with various coatings to enhance its performance, such as low-emissivity coatings that improve energy efficiency.

What are the properties of clear float glass?

There are several types of clear float glass (soda lime glass), each with its own unique properties and applications. Some of the most common types include:

Affordable

Clear float glass is relatively inexpensive compared to other types of glass, making it a popular choice for many applications.

Transparency and clarity

Clear float glass has a high level of transparency and clarity, which makes it ideal for applications where optical quality is essential, such as windows, mirrors, and display screens.

High tensile strength

Clear float glass has a high tensile strength, which means that it can withstand significant amounts of force or pressure without breaking.

Thermal insulation

Clear float glass has excellent thermal insulation properties, which means that it can help to regulate the temperature in buildings and reduce energy consumption.

Low iron content

Clear float glass has a low iron content, which means that it has a slight greenish tint and can transmit more light than other types of glass.

Chemical resistance

Clear float glass is resistant to most chemicals, making it suitable for use in laboratories and other environments where chemical exposure is a concern.

Easy to fabricate

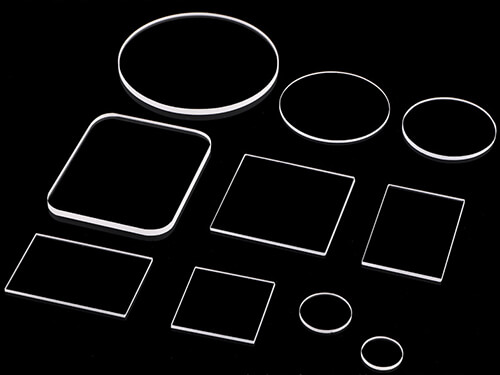

Clear float glass is easy to fabricate and can be cut, drilled, and shaped into a wide range of shapes and sizes.

Types of clear float glass (soda lime glass)?

Soda lime glass is a general term that refers to a family of glass types made from a combination of silica (SiO2), soda (Na2O), and lime (CaO). However, there are several different types of soda lime glass that have slightly different compositions and properties. Here are some of the common types of soda lime glass:

Tempered glass

This is a type of safety glass that is heat-treated to increase its strength and durability. It is commonly used in applications such as shower doors, glass walls, and automobile windows.

Annealed glass

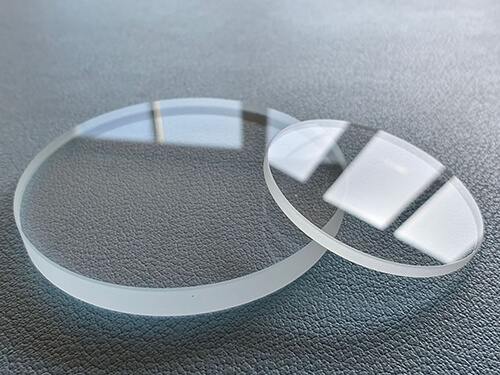

This is the most basic type of clear float glass and is used for general applications such as windows, doors, and mirrors. It is easy to fabricate and can be cut and shaped into a variety of sizes and shapes.

Low-iron glass

This is a type of clear float glass with a low iron content, which gives it a higher level of clarity and transparency than regular float glass. It is commonly used in applications such as architectural glass, display cases, and solar panels.

Coated glass

This is a type of clear float glass that has a coating applied to its surface to enhance its properties. For example, low-emissivity coatings can improve energy efficiency, while reflective coatings can reduce glare and heat gain.

Tinted glass

This is a type of clear float glass that has a color or tint added to it during the manufacturing process. It is commonly used in applications such as automobile windows, building facades, and decorative glass.

Laminated glass

This is another type of safety glass that consists of two or more layers of annealed glass bonded together with a layer of plastic film. It is commonly used in applications such as windows, skylights, and hurricane-resistant doors and windows.

Applications of the custom clear float glass (soda lime glass)?

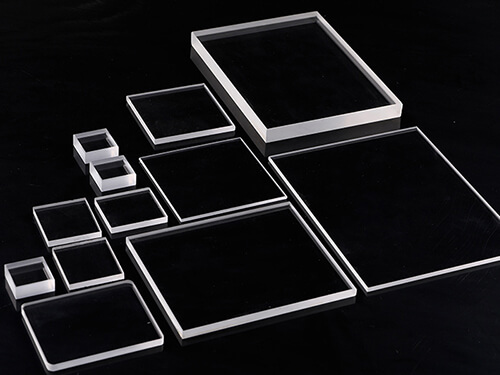

Custom clear float glass (soda lime glass) plate, panel, sight windows, and lens cutting services can be used in a wide range of applications, such as:

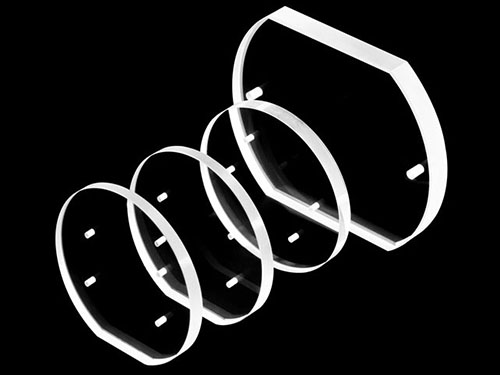

Sight windows

Custom clear float glass can be used as sight windows in industrial applications, such as boilers, tanks, and reactors. Sight windows allow operators to see inside the equipment without opening it, reducing the risk of accidents and improving efficiency.

Lens cutting

Clear float glass can be cut and shaped into lenses for use in cameras, telescopes, and other optical devices. Custom sizes and shapes can be cut to meet the specific requirements of the device.

Display cases

Clear float glass can be used to create display cases for retail stores, museums, and other institutions. Custom sizes and shapes can be cut to fit specific items, and the glass can be tempered or laminated for added durability and safety.

Windows and doors

Clear float glass is commonly used for windows and doors in residential and commercial buildings. Custom sizes and shapes can be cut to fit specific openings, providing a seamless and attractive appearance.

Glass shelves

Custom clear float glass can be cut to size and used for shelves in homes, offices, and retail spaces. Glass shelves provide a modern and minimalist look, and are ideal for displaying items such as books, artwork, and retail products.

Tabletops

Clear float glass can be used to create tabletops for homes, offices, and restaurants. Custom sizes and shapes can be cut to fit specific tables, and the glass can be tempered or laminated for added durability and safety.

Advantages of clear float glass (soda lime glass) custom laser cut parts?

Clear float glass (soda lime glass) is a popular choice for a wide range of applications due to its many advantages, including:

Cost-effective

Clear float glass is a cost-effective material, making it a popular choice for a wide range of applications. It offers excellent value for money while still providing high-quality performance.

Clarity

Clear float glass has excellent clarity, allowing it to transmit light without distortion or coloration. This makes it ideal for use in windows, doors, and other applications where visibility is important.

Versatility

Clear float glass can be cut and shaped into a variety of sizes and shapes, making it a versatile material for a wide range of applications. It can be tempered, laminated, coated, or tinted to enhance its properties and meet specific requirements.

Durability

Clear float glass is strong and durable, making it resistant to damage from impact, temperature changes, and other factors. It is a reliable material for use in applications such as windows, doors, and architectural glass.

Energy-efficient

Clear float glass can be coated with low-emissivity coatings to improve its energy efficiency by reducing heat transfer through windows. This makes it an ideal choice for use in energy-efficient buildings and homes.

Sustainable

Clear float glass is a sustainable material that can be recycled and reused. This reduces the environmental impact of the glass industry and helps to conserve natural resources.

Disadvantages of clear float glass (soda lime glass)?

While clear float glass (soda lime glass) offers many advantages, there are also some disadvantages to consider. These include:

Fragility

Clear float glass is not as strong as some other types of glass, such as tempered or laminated glass. It can break or shatter upon impact, posing a safety hazard if not properly handled or installed.

Heat resistance

Clear float glass is not as heat-resistant as some other types of glass, such as borosilicate glass. It may crack or break when exposed to high temperatures, making it unsuitable for certain applications such as laboratory glassware.

UV protection

Clear float glass does not provide adequate protection against ultraviolet (UV) radiation from the sun. This can cause fading, discoloration, and other damage to furniture, flooring, and other materials inside buildings.

Noise insulation

Clear float glass does not provide as much noise insulation as some other types of glass, such as laminated glass. This can be a disadvantage in noisy environments, such as airports or busy streets.

Energy efficiency

While clear float glass can be coated with low-emissivity coatings to improve its energy efficiency, it is not as effective as some other types of glass, such as insulated or triple-pane glass.

Get Your Custom clear float glass (soda lime glass) Parts Into Production Today

Want to save time and money on your clear float glass (soda lime glass) project? Contact us now. Our factory provides high-quality precision custom clear float glass (soda lime glass) products at very competitive prices and fast production times. We support free sample service.