Custom Clear glass Service

High-quality precision custom clear glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is Clear glass ?

Clear glass is a type of glass that is transparent and colorless. It is also known as soda-lime glass or annealed glass and is the most common type of glass used in household and commercial applications.

Clear glass is made by heating a mixture of silica sand, soda ash, and limestone to a high temperature until it melts and becomes a liquid.

The liquid glass is then shaped into flat sheets or molded into various shapes and sizes.

Clear glass has a high transmission of visible light and is commonly used for windows, doors, and other architectural applications where transparency and clarity are important. It can also be used for various types of decorative objects such as vases, bowls, and figurines.

One of the advantages of clear glass is that it is relatively inexpensive to produce and widely available. It is also easy to clean and maintain, making it a popular choice for many applications.

What are the properties of Clear glass ?

Chemical Properties

Clear glass is chemically inert and does not react with most chemicals. It has a high resistance to corrosion and does not rust.

Electrical Properties

Clear glass is an insulator and does not conduct electricity. It has a high dielectric strength, meaning that it can withstand high voltage without breaking down.

Mechanical Properties

Clear glass is a brittle material and has low resistance to impact. It has a high tensile strength and can withstand tensile forces without breaking. It is a poor conductor of sound.

Physical Properties

Clear glass is a hard material and has a Mohs hardness of around 5.5. It is a non-porous material and is impermeable to liquids and gases. It has a high density, with typical values around 2.5 g/cm3.

Thermal Properties

Clear glass has a low thermal conductivity, meaning that it is a poor conductor of heat. It has a high thermal expansion coefficient, meaning that it expands and contracts significantly with changes in temperature. It has a high melting point and can withstand high temperatures.

Optical Properties

Clear glass is transparent, allowing visible light to pass through it without significant distortion or absorption. It has a low refractive index, meaning that light passes through it without bending significantly. It has a high transmittance for visible light.

Types of Clear glass ?

There are several types of clear glass, each with its own specific properties and applications. Here are some of the most common types of clear glass:

Soda-lime glass

This is the most common type of clear glass and is used in most household applications, such as windows, mirrors, and glassware. It is made by melting silica, soda ash, and lime together.

Borosilicate glass

This type of glass is known for its high resistance to thermal shock, making it ideal for use in laboratory glassware, cookware, and lighting fixtures. It is made by melting silica and boron oxide together.

Tempered glass

Also known as safety glass, tempered glass is four to five times stronger than regular glass and is designed to shatter into small, rounded pieces when it breaks, reducing the risk of injury. It is made by heating regular glass to a high temperature and then cooling it rapidly.

Float Glass

This is a type of glass that is made by floating molten glass on a bed of molten metal. It is used for applications such as windows and mirrors and has a uniform thickness and excellent optical clarity.

Low-iron glass

This type of glass is made with a reduced iron content, which gives it a high degree of clarity and makes it ideal for use in applications where optical quality is important, such as high-end display cases and aquariums.

Optically clear glass

This is a specialized type of glass that is designed to have extremely high optical clarity and low distortion. It is used in applications where high-quality optics are required, such as camera lenses and telescopes.

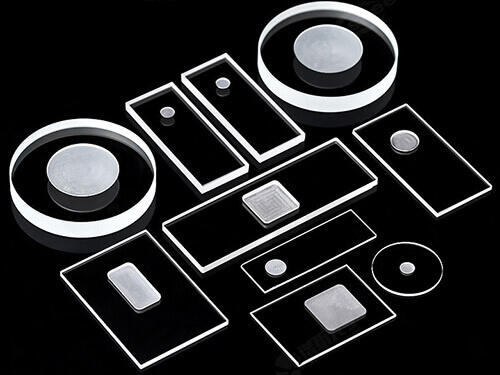

Applications of Clear glass cutting service?

Custom clear glass plate, panel, and lens cutting service is a process of cutting and shaping clear glass into specific sizes and shapes, as per the client's requirements. Here are some common applications of the custom clear glass plate, panel, and lens-cutting service:

Electronics

Glass is used in electronic devices such as smartphones, tablets, and computer screens. Glass cutting services can create custom-sized glass panels for different devices.

Lighting Fixtures

Clear glass is commonly used in lighting fixtures, such as pendant lights, chandeliers, and wall sconces. Custom clear glass cutting service can be used to create custom-sized glass panels and lenses for lighting fixtures that provide a clear, bright light.

Windows and Doors

Clear glass is commonly used for windows and doors to allow natural light to enter a space while providing a clear view of the outside. Custom clear glass cutting service can be used to create custom-sized windows and doors that fit perfectly in any space.

Architecture and Construction

Glass is a popular material for windows, doors, and partitions in modern buildings. Glass cutting services can provide custom-sized glass panels to fit any opening or design.

Glass Tabletops

Clear glass can be used to create glass tabletops for dining tables, coffee tables, and other furniture. Custom clear glass cutting services can be used to create custom-sized glass tabletops that fit perfectly on any piece of furniture.

Display Cases

Clear glass is often used to create display cases for retail stores, museums, and other spaces. Custom clear glass cutting services can be used to create custom-sized glass panels for display cases that showcase products or exhibits.

Advantages of clear glass custom laser cut parts?

Clear glass custom laser cut parts offer a range of advantages that make them an ideal choice for a wide range of applications. From precision and customization to quality and aesthetics, the benefits of using clear glass custom laser-cut parts are numerous. Here are some of the main advantages of using clear glass custom laser cut parts:

Precision

Laser cutting technology provides precision cuts with very fine tolerances, which means that clear glass custom laser cut parts can be made to exact specifications, ensuring a high degree of accuracy and consistency.

Customization

Clear glass custom laser cut parts can be designed to any shape or size, making them ideal for a wide range of applications. The laser cutting process can be used to create complex shapes and intricate designs, providing a high level of customization for a variety of needs.

Quality

Clear glass custom laser cut parts are made from high-quality materials that are resistant to scratches, breakage, and other forms of damage. This ensures that the finished product is of high quality and will last for a long time.

Versatility

Clear glass custom laser cut parts can be used for a variety of applications, including signage, display cases, furniture, and more. The versatility of laser cutting technology allows for a wide range of shapes and designs to be created, making it ideal for a variety of needs.

Aesthetics

Clear glass custom laser cut parts have a sleek, modern look that can add a touch of elegance to any application. The clarity of the glass allows for a high level of transparency, making it ideal for use in applications where visibility is important.

Disadvantages of clear glass custom glass cutting?

While clear glass custom laser cutting has several advantages, it also has some disadvantages. Here are a few potential disadvantages to consider:

Fragility

Clear glass custom laser cut parts can be fragile and prone to breaking, especially if the glass is thin. This can make them unsuitable for some applications where durability is critical.

Limitations on Thickness

Laser cutting technology is not suitable for cutting very thick glass, which means that clear glass custom laser cut parts may be limited in terms of the thickness of glass that can be used.

Safety concerns

The laser cutting process can create hazardous fumes and particles, which can be harmful to workers if proper safety precautions are not taken.

Design constraints

While laser cutting can create intricate and complex designs, there may be limitations on the types of designs that can be achieved. For example, very thin lines or small details may not be possible to create using laser cutting technology.

Clear glass custom laser cutting has some potential disadvantages, including fragility, limitations on thickness, safety concerns, and design constraints. However, these disadvantages can often be mitigated by taking appropriate precautions, selecting the right glass thickness, and carefully considering the application and design requirements.

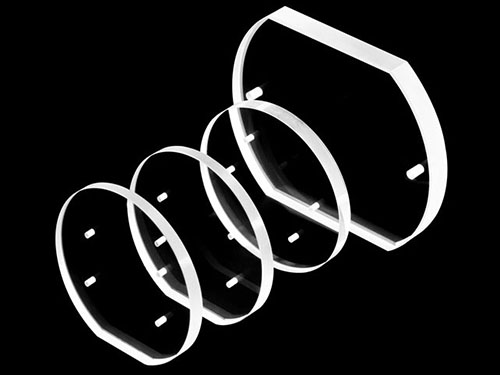

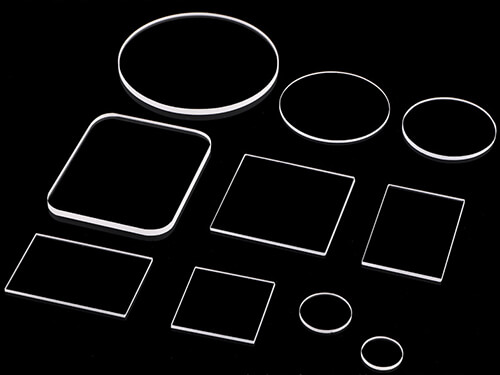

Custom Clear glass Parts We Can Manufacture

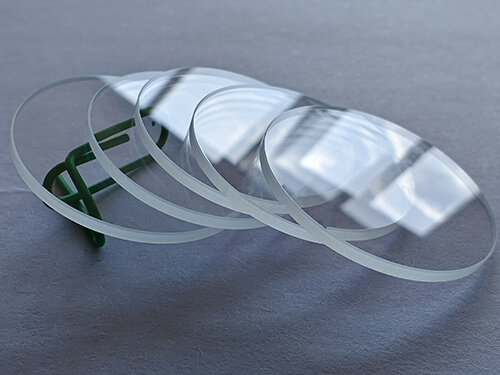

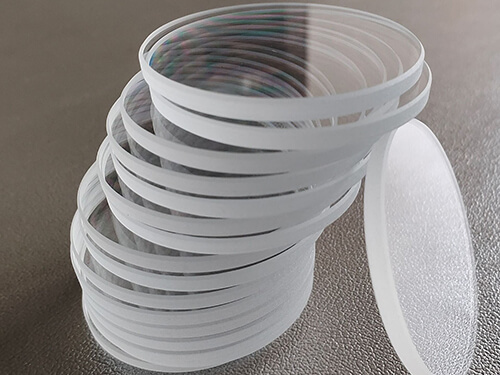

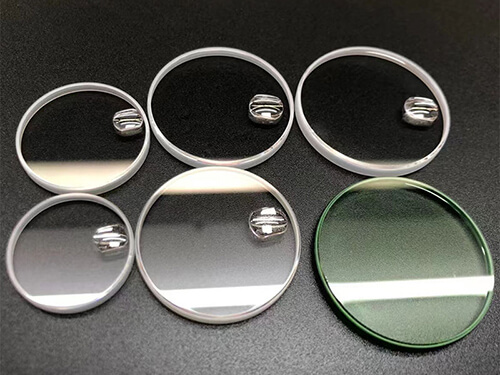

- Clear Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

What's custom Clear glass laser cutting service?

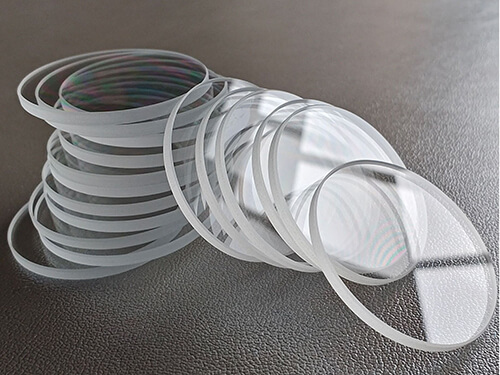

Laser cutting custom clear glass service is a process that uses a high-powered laser to cut and shape glass according to a precise design.

The laser is directed by a computer-controlled system that follows a digital blueprint to create intricate patterns, shapes, and designs on the glass surface.

Clear glass is a popular material for laser cutting because it is transparent and allows light to pass through, making it suitable for a variety of decorative and functional applications.

The laser cutting process can be used to create custom glass products such as engraved glass awards, personalized glass gifts, decorative glass panels, and more.

Laser cutting offers several advantages over traditional glass cutting methods, including greater precision, faster production times, and the ability to create complex designs.

It also minimizes the risk of glass breakage, which can occur with other cutting methods.

Laser cutting custom clear glass service is a versatile and effective way to create high-quality glass products that meet specific design requirements.

How to ensure the precision of the custom laser cutting Clear glass parts?

There are several steps that can be taken to ensure the precision of clear glass sheets cut to size service:

Accurate Measurements

The first step is to ensure that accurate measurements of the glass sheets are taken. The measurements should be double-checked and verified to ensure that they are correct.

Quality of the Glass

The quality of the glass used is also important. High-quality clear glass is less likely to have imperfections that could affect the precision of the cut.

State-of-the-Art Equipment

State-of-the-art equipment is essential for precision cutting. Laser cutting machines that use computer-controlled systems can cut glass with exceptional precision, minimizing errors and producing accurate cuts

Skilled Operators

Experienced operators who are trained in the use of laser cutting equipment can ensure that the cutting process is performed accurately and efficiently. They can also troubleshoot any issues that may arise during the cutting process.

Quality Control

A quality control process should be in place to inspect the glass sheets after they have been cut to ensure that they meet the required specifications. Any defects or deviations from the specifications should be identified and addressed promptly.

Precision in clear glass sheets cut to size service is achieved by a combination of accurate measurements, quality materials, state-of-the-art equipment, skilled operators, and quality control processes.

What's custom Clear glass CNC machining fabricate service?

Custom clear glass CNC machining fabricate service is a process that uses a computer numerical control (CNC) machine to create precise cuts and shapes on clear glass surfaces.

CNC machines use computer-aided design (CAD) software to produce a digital blueprint of the desired design, which is then translated into machine instructions that guide the CNC machine to create the final product.

CNC machining is a versatile process that can create intricate patterns and shapes on clear glass surfaces, making it suitable for a wide range of applications, such as architectural glass, art installations, display cases, and more.

CNC machines can cut, drill, and engrave glass with a high degree of precision, producing clean and accurate cuts that are difficult to achieve with traditional cutting methods.

Custom clear glass CNC machining fabricate service offers several advantages over other glass cutting and shaping methods.

It is a highly automated process that can reduce the risk of errors and produce consistent results, regardless of the complexity of the design.

CNC machining also allows for greater flexibility in design and customization, as it can create unique shapes and patterns that may not be possible with other methods.

Custom clear glass CNC machining fabricate service is a sophisticated and precise method for creating high-quality glass products that meet specific design requirements.

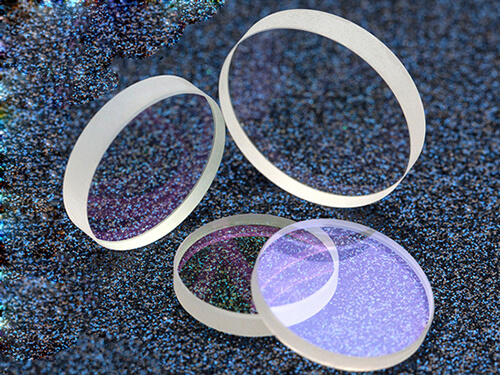

What are the coating types of Clear glass parts?

There are several coating types that can be applied to custom clear glass lenses, including:

Anti-reflective Coating

This coating reduces the amount of light reflected from the lens surface, which improves visibility and reduces glare. It is often used in eyeglasses, camera lenses, and other optical applications.

Scratch-resistant Coating

This coating makes the lens surface more resistant to scratches and abrasions, which can help extend the lifespan of the lens.

Anti-fog coating

Anti-fog coatings prevent the lens from fogging up, improving visibility in humid or cold conditions. They are commonly used in sports goggles and safety glasses.

UV-blocking Coating

This coating blocks harmful UV radiation from the sun, which can protect the eyes and skin from damage. It is often used in sunglasses, eyeglasses, and other outdoor applications.

Anti-fog Coating

This coating prevents fogging on the lens surface, which can improve visibility in humid or cold environments. It is often used in safety glasses, swimming goggles, and other applications where fogging is a concern.

Hydrophobic Coating

This coating repels water and other liquids from the lens surface, which can help keep the lens clean and improve visibility in wet environments. It is often used in camera lenses, eyeglasses, and other applications where water resistance is a concern.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom clear Glass Parts Into Production Today

Want to save time and money on your clear glass parts project? Contact us now. Our factory provides high-quality precision custom clear glass products at very competitive prices and fast production times. We support free sample service.