CNC Machining Service

High-quality glass & sapphire glass CNC machining service supplier at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass CNC Machining service?

Glass CNC machining service refers to the process of using computer numerical control (CNC) technology to shape and fabricate glass materials.

CNC machining involves the use of computer-controlled machinery and cutting tools to precisely remove material from a glass workpiece according to programmed instructions.

HY manufacturer specializes in CNC machining glass parts and sapphire parts. Our factory produces premium CNC machining glass and sapphire components at factory-direct prices.

Contact us to get a free quote for your custom CNC machining glass & sapphire glass parts.

What are the properties of glass & Sapphire Glass CNC Machining?

Glass & sapphire glass CNC machining possesses several properties that make it a popular method for shaping and fabricating glass & sapphire glass components. Here are some key properties associated with glass & sapphire glass CNC machining:

Precision

CNC machining offers high precision and accuracy, allowing for tight tolerances and precise dimensions to be achieved on glass components. The computer-controlled system ensures consistent machining according to the programmed design, resulting in precise and repeatable results.

Versatility

Glass CNC machining is versatile and can be applied to various types of glass, including float glass, tempered glass, laminated glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Customization

CNC machining allows for customization and flexibility in design. The programming stage enables easy modifications and adjustments to the design without requiring physical tool changes, allowing for quick prototyping and customized glass components. Complex shapes, intricate details, and specific features can be easily achieved.

Efficiency

CNC machining is an efficient process for shaping glass components. The automation of the process enables fast and precise material removal, reducing production time and increasing productivity. Additionally, the use of computer programming and advanced tooling minimizes manual labor requirements.

Surface Finish

Glass CNC machining can produce smooth surface finishes on glass components. The cutting tools used in CNC machining can be selected to achieve desired surface quality, whether it's a polished, satin, or textured finish. Additional finishing steps, such as polishing or surface treatment, can also be employed to further enhance the appearance and smoothness of the glass.

Complex Shapes and Features

CNC machining enables the creation of complex shapes, intricate details, and precise features on glass components. Three-dimensional contours, curved surfaces, internal cutouts, holes, threads, and intricate patterns can be achieved with high precision, allowing for greater design possibilities.

Material Preservation

CNC machining minimizes material waste due to its precise material removal capabilities. The machining process removes only the necessary material, resulting in minimal material loss and optimized material usage. This efficiency helps reduce production costs and optimize material resources.

Scalability

CNC machining is a scalable process, allowing for both small-scale production runs and large-scale manufacturing. The programmed instructions can be replicated for multiple glass components, ensuring consistency and accuracy across the production batch.

Automation and Integration

CNC machining can be integrated into automated production systems, offering enhanced efficiency and productivity. It can be linked with other manufacturing processes, such as CAD design, quality control systems, and robotic handling, to streamline the overall production workflow.

Types of glass & sapphire glass CNC Machining?

Glass & sapphire glass CNC machining encompasses various techniques and processes used to shape and fabricate glass components. Here are some common types of glass & sapphire glass CNC machining:

Glass & sapphire glass Milling

Glass & sapphire glass milling involves using CNC milling machines equipped with specialized cutting tools to remove material from a glass & sapphire glass workpiece. The milling process can create flat surfaces, contours, pockets, and intricate shapes on glass & sapphire glass components.

Glass & sapphire glass Drilling

Glass & sapphire glass drilling is the process of creating holes or openings in glass & sapphire glass using CNC machines. Specialized drill bits or diamond-tipped tools are used to cut through the glass & sapphire glass material, allowing for precise and accurate hole placement.

Glass & sapphire glass Engraving

Glass & sapphire glass engraving is the art of etching or carving designs, patterns, or text onto glass & sapphire glass surfaces. CNC machines with rotary engraving attachments or laser engraving capabilities can be used to achieve intricate and detailed engravings on glass & sapphire glass components.

Glass & sapphire glass Profiling

Glass & sapphire glass profiling involves shaping the edges or contours of glass & sapphire glass components using CNC machines. The cutting tools follow programmed paths to create specific edge profiles, chamfers, or bevels on the glass & sapphire glass.

Glass & sapphire glass Polishing

Glass & sapphire glass polishing is a finishing process that can be incorporated into CNC machining. After the initial machining operations, CNC machines with polishing attachments or tools can be used to achieve smooth and glossy surface finishes on glass & sapphire glass components.

Glass & sapphire glass Grinding

Glass & sapphire glass grinding involves removing material from the glass & sapphire glass surface to achieve precise thickness or flatness. CNC machines equipped with grinding wheels or abrasive belts can be used to perform grinding operations on glass & sapphire glass components.

Glass & sapphire glass Grooving

Glass & sapphire glass grooving is the process of creating grooves or channels on glass & sapphire glass surfaces. CNC machines with specialized cutting tools or diamond-tipped wheels can be used to groove glass & sapphire glass components, which are commonly used in applications such as architectural glass systems or decorative glass & sapphire glass.

Glass & sapphire glass Beveling

Glass & sapphire glass beveling refers to creating angled or slanted edges on glass & sapphire glass components. CNC machines equipped with beveling tools or grinding wheels can be used to achieve precise and uniform bevels on glass & sapphire glass edges.

Glass & sapphire glass Sculpting

Glass & sapphire glass sculpting involves shaping glass & sapphire glass components into artistic or sculptural forms. CNC machines with multi-axis capabilities can be used to create intricate and complex three-dimensional shapes and sculptures from glass & sapphire glass materials.

What are the benefits of glass & Sapphire glass CNC Machining?

Precision

CNC machining provides high precision and accuracy, allowing for tight tolerances and complex geometries to be achieved on glass components. The computer-controlled system ensures consistent machining according to the programmed design.

Versatility

Glass CNC machining can be applied to various types of glass, including float glass, sapphire glass, clear glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Customization

CNC machining allows for customization and flexibility in design. The programming stage enables easy modifications and adjustments to the design without requiring physical tool changes, allowing for quick prototyping and customized glass components.

Efficiency

CNC machining is an efficient process, enabling fast and precise material removal with minimal wastage. The automation of the process reduces labor requirements and increases productivity.

Complex Shapes and Features

CNC machining can produce complex shapes, intricate details, and precise features on glass components. It allows for the creation of three-dimensional contours, curved surfaces, internal cutouts, and intricate patterns.

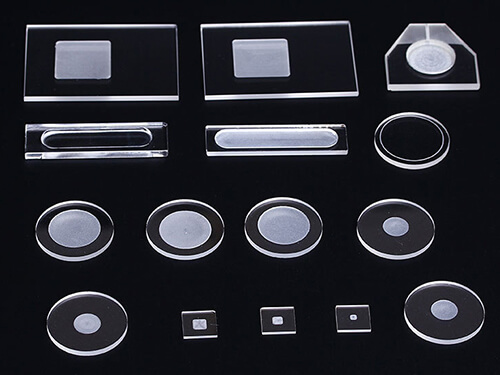

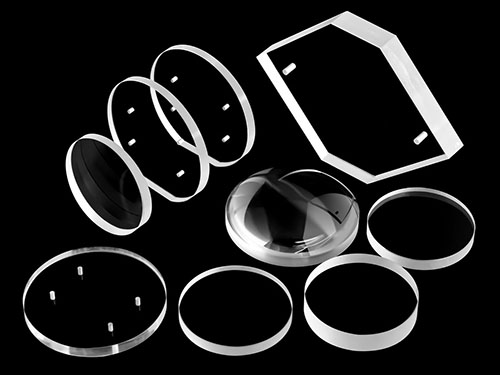

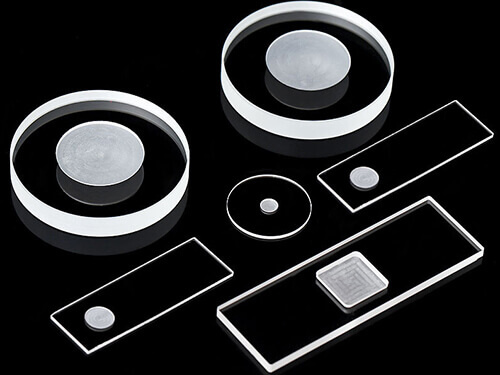

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & sapphire glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.