High-Quality Custom Glass Parts Factory At Unbeatable Prices Saving Your Cost

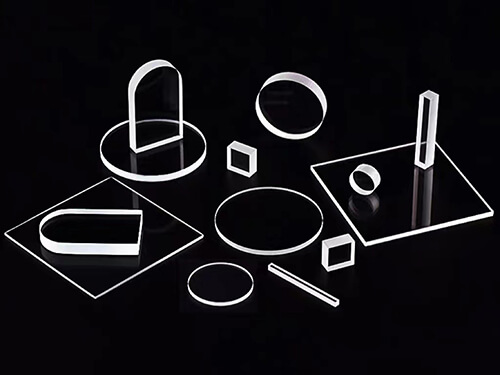

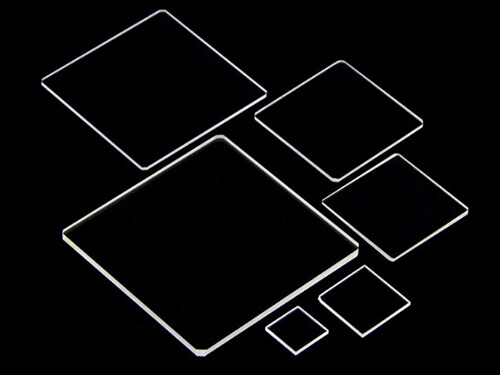

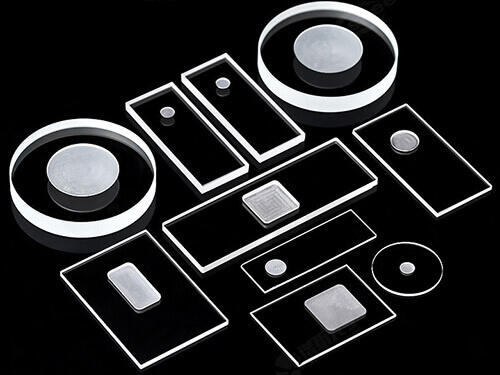

As a leading manufacturer of OEM custom glass-cutting services in China, we have the full experience to produce high-quality standards of custom laser-cut glass parts at competitive prices that can meet your custom request.

Contact us now to request a quote for your OEM custom glass cut-to-size parts or get a free sample now.

Our custom glass cuttings Capabilities

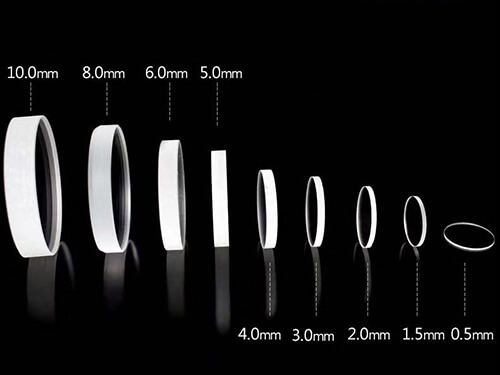

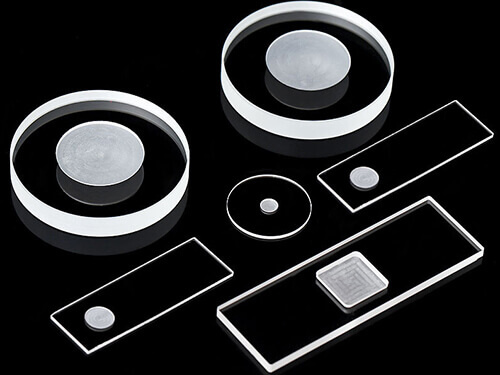

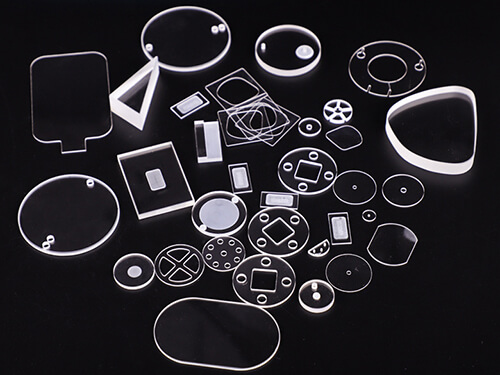

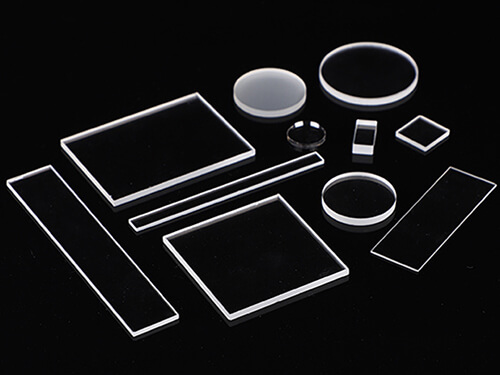

As an OEM custom laser-cutting glass manufacturer with 12+ experience, we offer our clients a wide range of services. We specialize in creating custom size and shaped glass products to meet our customers’ specific needs and requirements.

Our advanced laser-cutting technology allows us to produce precise and intricate cuts with high accuracy and efficiency. We can work with various glass materials, including clear glass, soda lime glass, borosilicate glass, quartz (Fused Silica), frosted glass, tempered glass, anti-fingerprint glass, clear float glass (soda lime), low iron glass (soda lime), and anti-reflection (AR) glass, to create a wide range of products. From glass lens replacement, watch glass, glass lens, glass disc, flashlight lens cover, tempered glass panel, sight glass window, round sight glass, touch glass, switch screen protector, switch OLED, flashlight lens, tempered glass lens, screen protector, smart light switch, and custom tempered glass lenses, frosted glass lens to custom products.

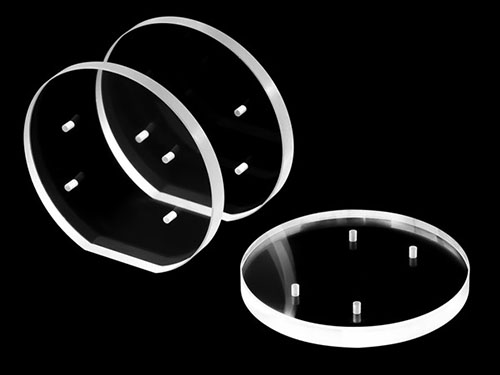

In addition to laser cutting, we offer a range of value-added services, including polishing, edging, frosted, drilling, beveling, fillet, chamfer, tempering, and so on to help create the perfect finished product for our clients.

Our team of experienced professionals is dedicated to providing the highest quality products and exceptional customer service. We take pride in delivering top-notch products that meet the needs of our customers and exceed their expectations.

If you have a project in mind and are in need of an OEM custom glass cut service, we would love to help bring your vision to life. Please do not hesitate to contact us with any questions or to discuss your project in more detail.

We support free sample service to save your cost.

The Advantage Of HY's OEM custom glass cut Service

With years of experience in custom glass-cut parts manufacturing, our factory has the expertise and technology to produce high-quality glass-cutting parts. We specialize in producing high-quality laser-cut glass parts that meet your specific needs. The advantages of our laser-cut glass service are as below:

- NO MOQ

- Free Sample Service

- Super Competitive price

- Easy online ordering

- Strictly quality control

- Satisfaction guaranteed

- Various processing techniques

- Custom cut exactly to your request

- Various glass materials for your choice

- Production time as fast as 5 business days

Custom Glass Components We Can Manufacture

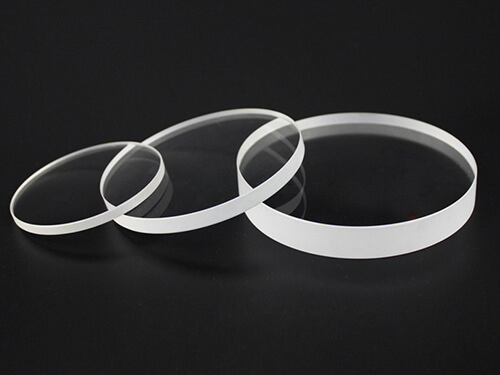

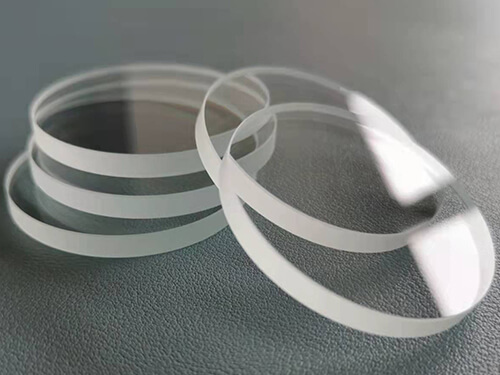

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

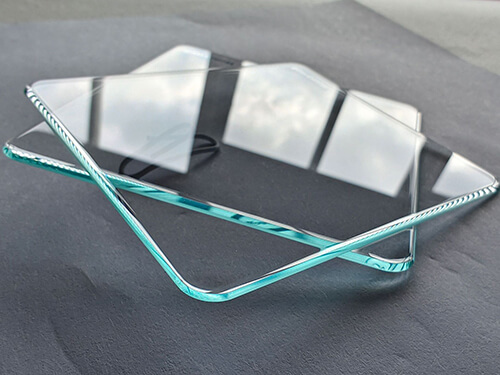

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

Types of Glass Suitable for Laser Cutting?

As an OEM custom glass cut-to-size supplier in China, we offer various glass materials for your high-quality custom glass-cutting parts projects. Whatever glass materials you need, our factory can provide custom glass sheets cut to size parts that meet your specific requirements. The glass materials we mainly used are as below:

Borosilicate glass: This type of glass has a low coefficient of thermal expansion, making it resistant to thermal shock. It is commonly used in applications where the glass may be subjected to temperature fluctuations.

Soda-lime glass: This is the most common type of glass and is used in a wide range of applications. It is relatively inexpensive and has good optical clarity.

Fused silica: This type of glass has a very low coefficient of thermal expansion and is resistant to thermal shock. It is commonly used in applications where the glass may be subjected to extreme temperatures.

Pyrex: This type of glass is made of borosilicate and is known for its strength and durability. It is commonly used in applications where the glass may be subjected to temperature fluctuations or mechanical stress.

Tempered glass: This type of glass is treated with heat and chemicals to make it stronger and more resistant to breaking. It is commonly used in applications where safety is a concern.

Stained glass: This type of glass is made by adding metallic oxide to the glass during the manufacturing process, resulting in a range of colors and patterns. It is commonly used in decorative applications.

K9 glass: This type of glass is a type of optical glass that is commonly used in lenses and prisms due to its high refractive index and low dispersion. It is made from a mixture of silicon dioxide and boron oxide and is often referred to as “BK7” glass in the United States. K9 glass is known for its excellent optical properties, including high transmittance and minimal distortion, and is frequently used in scientific and medical equipment, as well as in cameras and telescopes.

Extra Service Of Our Custom Glass Cut Service

Every one of our departments is devoted to reducing the cost and providing high-quality custom glass and sapphire glass parts for you. Reasonable price, fast production time, and high quality is our goal.

Frosted

Frosted glass is a type of decorative glass with a smooth, frosted appearance. This effect can be achieved through acid etching. During the acid etching process, the glass is treated with hydrofluoric acid or other chemicals that dissolve the surface of the glass, leaving behind a frosted, opaque appearance. Frosted glass can provide privacy and diffuse light, and is more durable and resistant to scratching and wear.

Tempering

Tempered glass is a type of safety glass that is treated with heat and rapid cooling to increase its strength and durability. This process, known as tempering, involves heating the glass to a temperature of approximately 620°C and then rapidly cooling it with air jets. The result is a glass that is approximately four times stronger than untreated glass and can better resist thermal stress and impact.

Stepped

Step glass is glass with a step above it. Processing stepped glass is generally processed by a CNC engraving and milling machine. Step glass is widely used in various instruments, underground lamps, electrical equipment, high-temperature lamps, etc. Compared with other glass, it has the performance of shock resistance, anti-theft, bullet-proof, and explosion-proof.

Drilling

Glass drilling is a type of decorative treatment that involves creating a hole or multiple holes in the surface of the glass. This process is typically achieved through the use of a high-speed diamond drill bit that is specially designed to cut through glass. Glass drilling is a versatile and effective way to enhance the functionality and decorative appeal of glass surfaces. It can be used in a variety of applications.

Edging

Glass edging is a process of smoothing and shaping the edges of the glass to create a finished look. This process involves using a grinding wheel or sanding belt to remove any sharp edges or imperfections on the edge of the glass. Glass edging can help to prevent injury from sharp edges and increase the strength and durability of the glass, as it can prevent chipping and cracking.

Polishing

Glass polishing is a process of smoothing the surface of the glass to remove scratches, marks, and other imperfections. This process involves using an abrasive substance and a polishing wheel to gently buff the glass until it becomes smooth and shiny. There are several types of glass polishing techniques, including mechanical polishing, chemical polishing, and flame polishing.

Silk Printing

Glass silk-screen printing, also known as glass screen printing, is a decorative treatment that involves applying a pattern or design onto the surface of the glass using a specialized screen printing process. One of the advantages of glass silk-screen printing is that it allows for a high degree of precision and detail in the design, allowing for intricate patterns and designs to be applied to the glass surface.

Coating

Glass coating is a type of decorative treatment that involves the application of a thin film or layer onto the surface of the glass. This process is typically achieved through a variety of methods, including chemical vapor deposition, sputtering, or spraying. Glass coating is a versatile and effective way to enhance the appearance and functionality of glass surfaces, and can be used in a variety of applications.

Chamfer

Glass beveling involves grinding and polishing the edges of the glass to create a sloping surface, also known as a chamfer. This is achieved by using specialized machinery and abrasive tools to remove the sharp edges of the glass, creating a smooth and polished finish. Glass beveling can make the glass safer as it removes the sharp edges. Beveled edges can help to prevent chipping and cracking of the glass.

Radius

Glass fillet (radius) is the process of the rounded edge of the glass. It is often added to improve the safety and appearance of the glass. The process of creating a glass fillet (radius) typically involves grinding and it’s focused on producing a smooth, rounded edge that is both aesthetically pleasing and safe to handle. By eliminating sharp corners and edges, the risk of injury is reduced.

What are the advantages of Laser Cut glass?

Precision: Laser cutting allows for very precise cuts, with a high level of accuracy and repeatability. This is especially important when working with glass, as it is a brittle material that is prone to cracking or shattering if it is not cut accurately.

Cost-effectiveness: Laser cutting is generally more cost-effective than other methods of cutting glass, especially for small-scale or custom projects.

Speed: Laser cutting is a very fast process, which means that it can be used to quickly cut and shape glass into the desired shapes and sizes.

Non-contact processing: Laser cutting is a non-contact process, which means that it does not create any mechanical stress on the material being cut. This is especially important when working with glass, as it is prone to cracking or shattering when subjected to mechanical stress.

Versatility: Laser cutting can be used to cut a wide variety of shapes and sizes, making it a very versatile option for working with glass.

Clean cuts: Laser cutting produces clean, smooth cuts with minimal burrs or rough edges, which can be important for certain applications.

Safety: Laser cutting is generally a safe process, as there are no hazardous materials or cutting tools involved.

Applications of Custom Size Glass Parts?

LED Lighting Lens: Frosted glass disc can be used as the flashlight glass lens to help to reduce glare and create a more even and comfortable light output.

Smart light switch: Custom tempered glass parts can be used to produce custom-size display panels and switch screen protectors.

Optics: Custom glass cut parts can be used to produce lenses, prisms, and other optical components.

Electronic devices: Laser-cutting glass parts can be used in the production of electronic devices such as smartphones, tablets, and laptops.

Architectural products: Glass cutting parts can be used to produce custom size glass panels and partitions for use in buildings and construction projects.

Medical devices: Custom glass cutting parts can be used to produce precision parts for use in medical devices such as endoscopes and surgical instruments.

Automotive: Glass-cutting service parts can be used to produce custom size windows and other glass components for use in the automotive industry.

Art and design: Laser-cut glass parts can be used to produce custom size glass pieces for use in art and design projects.

Aerospace: Custom glass cutting parts can be used to produce custom size glass components for use in the aerospace industry.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Cilents & Feedbacks

Put Your Custom Glass Parts Into Production Today

Want to save time and money on your custom glass parts project? Contact us now. Our factory provides high-quality precision custom glass products at very competitive prices and fast production times. We support free sample service.

More Knowledge Of Custom Glass Service

Table of Contents

1. The Ultimate Guide To Custom Laser Cut Glass Parts Machining & Buying F.A.Q

Custom laser-cut glass parts machining enables us to produce high-precision quality parts with the utmost efficiency, accuracy, and competitive price.

It’s easy to achieve up to 99.5% quality precision and tight tolerances for your glass-cutting parts to achieve high customer satisfaction.

This FAQ guide will help you understand custom glass machining completely and how HY performs it with utmost precision and cost-efficacy.

You will learn what custom options HY offer, learn glass machining benefits and capabilities for your parts, and how they can be extremely productive.

2. What is glass?

Glass is an inorganic, transparent, and amorphous material that is made from silica (silicon dioxide, SiO2) and other additives. It is typically made by melting silica, soda, and lime together at high temperatures, then allowing the molten material to cool rapidly.

Glass is a versatile material that is used in a wide range of applications, including construction, electronics, optics, and more. It is known for its transparency, durability, and ability to transmit light.

There are many different types of glass, including soda-lime glass, borosilicate glass, tempered glass, laminated glass, and more. Each type of glass has its own unique properties and is suitable for different applications.

Glass is an important and widely used material in many industries, and its versatility and unique properties make it an ideal choice for a wide range of applications.

3. What are glass material properties?

Glass is a type of inorganic, transparent, and amorphous material that is made from silica (silicon dioxide, SiO2) and other additives. Some of the material properties of glass include:

Transparency:

Glass is known for its transparency, which allows it to transmit light and enable visibility through it.

Hardness:

Glass is a hard and brittle material that is resistant to wear and tear.

Thermal stability:

Glass is a good thermal insulator and is resistant to thermal shock. However, some types of glass may be more prone to thermal expansion and contraction than others.

Chemical stability:

Glass is resistant to chemical attack and is not affected by most acids and bases.

Electrical insulation:

Glass is an insulator and does not conduct electricity.

Density:

The density of glass varies depending on the type and composition of the glass.

Optical properties:

Glass has good optical clarity and is used in a wide range of applications, including optics and electronic displays.

Strength:

Glass is a strong material, but it is brittle and prone to breaking under stress. Some types of glass, such as tempered glass, are stronger and more resistant to breaking than others.

Elasticity:

Glass is a brittle material and does not have much elasticity. It is prone to cracking and breaking under stress.

4. Types of glass?

Soda-lime glass:

This is the most common type of glass and is used in a wide range of applications. It is relatively inexpensive and has good optical clarity.

Borosilicate glass:

This type of glass has a low coefficient of thermal expansion, making it resistant to thermal shock. It is commonly used in applications where the glass may be subjected to temperature fluctuations.

Fused silica:

This type of glass has a very low coefficient of thermal expansion and is resistant to thermal shock. It is commonly used in applications where the glass may be subjected to extreme temperatures.

Pyrex:

This type of glass is made of borosilicate and is known for its strength and durability. It is commonly used in applications where the glass may be subjected to temperature fluctuations or mechanical stress.

Tempered glass:

This type of glass is treated with heat and chemicals to make it stronger and more resistant to breaking. It is commonly used in applications where safety is a concern.

Laminated glass:

This type of glass is made by sandwiching a layer of plastic between two layers of glass. It is stronger and more resistant to breaking than regular glass and is commonly used in applications where safety is a concern.

Stained glass:

This type of glass is made by adding metallic oxide to the glass during the manufacturing process, resulting in a range of colors and patterns. It is commonly used in decorative applications.

Low-emissivity glass:

This type of glass is coated with a thin layer of metal or metallic oxide that reflects infrared light, reducing the amount of heat that is transmitted through the glass. It is commonly used in energy-efficient window applications.

Heat-strengthened glass:

This type of glass is treated with heat to increase its strength and resistance to breaking. It is stronger than regular glass but not as strong as tempered glass.

Float glass:

This type of glass is made by floating molten glass on a bed of molten metal, resulting in a smooth, flat surface. It is commonly used in a wide range of applications, including windows, mirrors, and more.

5. What's Laser Cutting Glass Service?

Laser cutting glass is a process that uses a highly focused laser beam to cut and shape glass materials with precision and accuracy. Laser cutting is a popular choice for glass processing because it can produce precise cuts and intricate shapes with a high level of repeatability and consistency. The laser beam is able to cut through the glass without creating any mechanical stress on the material, which means that the cuts are clean and smooth and there is minimal risk of cracking or shattering.

In a laser-cutting glass service, a laser beam is directed onto the surface of the glass using a computer-controlled system. The laser beam is focused and intensified to the point where it is able to vaporize the glass material as it cuts through it. The computer system can be programmed to follow a specific cutting path or to create a custom shape based on a digital design. The speed and intensity of the laser beam can be adjusted to achieve different cutting depths and finishes.

Laser-cutting glass services are often used in a variety of industries, including architecture, automotive, electronics, and jewelry design. Laser-cutting glass can be used to create custom-fit windows, decorative panels, and other architectural elements, as well as automotive components, electronic devices, and jewelry pieces. The high level of precision and accuracy that laser cutting offers make it an ideal choice for a wide range of applications where precise cuts and complex shapes are required.

6. Which glass is best for laser cutting?

There are several types of glass that are suitable for laser cutting, including:

Borosilicate glass:

This type of glass has a low coefficient of thermal expansion, making it resistant to thermal shock. It is commonly used in applications where the glass may be subjected to temperature fluctuations.

Soda-lime glass:

This is the most common type of glass and is used in a wide range of applications. It is relatively inexpensive and has good optical clarity.

Fused silica:

This type of glass has a very low coefficient of thermal expansion and is resistant to thermal shock. It is commonly used in applications where the glass may be subjected to extreme temperatures.

Pyrex:

This type of glass is made of borosilicate and is known for its strength and durability. It is commonly used in applications where the glass may be subjected to temperature fluctuations or mechanical stress.

Tempered glass:

This type of glass is treated with heat and chemicals to make it stronger and more resistant to breaking. It is commonly used in applications where safety is a concern.

Laminated glass:

This type of glass is made by sandwiching a layer of plastic between two layers of glass. It is stronger and more resistant to breaking than regular glass and is commonly used in applications where safety is a concern.

Stained glass:

This type of glass is made by adding metallic oxide to the glass during the manufacturing process, resulting in a range of colors and patterns. It is commonly used in decorative applications.

The best type of glass for laser cutting will depend on the specific requirements of the application, including the type of laser being used, the desired precision of the cut, and the desired properties of the final product. It is important to choose a type of glass compatible with the laser-cutting process that meets the application’s specific needs.

7. What's Custom Glass CNC Machining Service?

Custom glass CNC machining service is a manufacturing process that uses computer numerical control (CNC) technology to produce custom glass components with high precision and accuracy. This service involves the use of computer-aided design (CAD) software to design the glass component, which is then loaded into a CNC machine. The machine then uses a diamond-tipped cutting tool to shape and polish the glass component according to the exact specifications provided by the CAD design.

This process is ideal for producing glass components with complex shapes, intricate designs, and tight tolerances that cannot be achieved through traditional glass fabrication methods. Custom glass CNC machining service is commonly used in industries such as optics, aerospace, medical devices, and electronics, where precision and accuracy are critical.

Some examples of glass components that can be produced using custom glass CNC machining service include lenses, mirrors, prisms, waveguides, filters, and glass housings for electronic devices.

8. Types of Glass Suitable for CNC Machining?

CNC machining is a precise manufacturing method that uses computer-controlled machines to cut, drill, and shape materials. When it comes to glass, not all types are suitable for CNC machining. Some of the types of glass that are suitable for CNC machining include:

Borosilicate glass:

This type of glass is highly resistant to thermal shock and is commonly used in laboratory equipment, lighting, and cookware. It is an ideal choice for CNC machining due to its hardness and resistance to chemical corrosion.

Fused quartz glass:

This type of glass is highly pure and has excellent thermal and mechanical properties. It is commonly used in the semiconductor industry and is suitable for CNC machining due to its hardness and durability.

Soda-lime glass:

This type of glass is commonly used in windows, bottles, and jars. It is less durable than borosilicate or fused quartz glass, but it is still suitable for CNC machining.

Pyrex glass:

This is a type of borosilicate glass that is known for its durability and resistance to thermal shock. It is commonly used in laboratory equipment and is suitable for CNC machining.

It is important to note that not all types of glass are suitable for CNC machining, and it is essential to consult with an HY glass manufacturer or HY CNC machining expert before choosing a glass type for your project.

9. What are the surface finishes for custom machining glass parts?

There are several types of surface finishes for glass parts, including:

Polished Finish:

This finish is achieved by using abrasives to create a smooth and shiny surface on the glass.

Sandblasted Finish:

Sandblasting is a process where a high-pressure stream of sand is used to etch the surface of the glass, creating a frosted or matte finish.

Acid-Etched Finish:

This process involves using acid to etch the surface of the glass, creating a matte finish.

Frosted Finish:

Frosted glass is created by sandblasting or acid-etching the surface of the glass, creating a surface that scatters light and gives it a matte appearance.

Satin Finish:

Satin glass has a smooth, matte surface that diffuses light and gives a soft glow.

Beveled Edge Finish:

A beveled edge is created by cutting and polishing the edge of the glass at an angle, giving it a decorative and elegant look.

Mirrored Finish:

A mirrored finish is achieved by applying a reflective coating to the surface of the glass, creating a surface that reflects light and gives a reflective appearance.

Tinted Finish:

Tinted glass is created by adding color to the glass during manufacturing, giving it a colored appearance.

Laminated Finish:

Laminated glass is created by bonding two or more layers of glass together with a plastic interlayer, creating a strong and durable surface.

Textured Finish:

Textured glass is created by rolling or pressing the glass with a patterned roller or plate, creating a surface with a decorative pattern or texture.

10. What Is The Laser Cutting Glass Process?

The laser-cutting glass process involves the use of a laser beam to cut through a glass material to produce custom size and shaped products. The process typically involves the following steps:

Setup:

The laser cutting machine and the glass material are prepared for the cutting process. This may involve setting up the laser cutting machine, adjusting the laser beam parameters, and positioning the glass material in the cutting area.

Focusing:

The laser beam is focused onto the surface of the glass material using a focusing lens. The focus of the laser beam determines the size and shape of the cut and the precision of the cut.

Cutting:

The laser beam is directed over the surface of the glass material, cutting through the material as it moves. The laser beam is guided over the material using a system of mirrors or a computer-controlled beam steering system.

Finishing:

The cut glass parts are removed from the cutting area and may be subjected to additional finishing processes, such as cleaning or polishing, to remove any burrs or defects.

The laser cutting glass process is a precise and efficient method for producing custom size and shaped glass products. It is suitable for a wide range of applications, including electronics, construction, and more.

11. What kind of laser head is needed to cut glass sheets?

There are several types of laser heads that can be used to cut glass sheets, including CO2 laser heads and fiber laser heads.

CO2 laser heads are commonly used for cutting glass sheets and other materials. They use a beam of CO2 gas to generate a high-energy laser beam that can cut through a wide range of materials, including glass. CO2 laser heads are suitable for cutting thin to medium-thickness glass sheets and are known for their precision and accuracy.

Fiber laser heads are another type of laser head that can be used to cut glass sheets. They use a beam of light generated by a fiber laser to cut through materials, including glass. Fiber laser heads are suitable for cutting thin to thick glass sheets and are known for their high speed and efficiency.

The best type of laser head for cutting glass sheets will depend on the specific requirements of the application, including the thickness of the glass sheets, the desired precision of the cut, and the desired speed and efficiency of the process. It is important to choose a laser head that is compatible with the laser cutting machine and meets the specific needs of the application.

12. What are the advantages and disadvantages of Laser Cutting Glass?

Some advantages of laser cutting glass include:

Precision:

Laser cutting allows for precise cuts with a high level of accuracy, making it ideal for applications that require precise cuts or intricate shapes.

Speed:

Laser cutting is a fast process, allowing for the production of large quantities of parts in a short amount of time.

Versatility:

Laser cutting can be used to cut a wide variety of materials, including different types and thicknesses of glass.

Flexibility:

Laser cutting can produce a wide range of shapes and patterns, making it suitable for a variety of applications.

Clean cuts:

Laser cutting produces clean, smooth cuts with minimal burrs or defects.

Some disadvantages of laser cutting glass include:

Material limitations:

Laser cutting may not be suitable for all types of materials, including some types of glass.

Safety concerns:

Laser cutting produces high-energy beams that can be hazardous, requiring the use of protective equipment and measures to ensure the safety of operators.

13. What Is The Importance Of Tight Tolerances In Laser Cutting Glass Service?

Tight tolerances are important in laser cutting glass service because they ensure the precision and accuracy of the final product. Tight tolerances refer to the level of precision that is required in the cutting process, with smaller tolerances indicating a higher level of precision.

In many applications, tight tolerances are critical to the performance and function of the final product. For example, in the electronics industry, precise cuts may be necessary to ensure the proper fit and function of components. In the construction industry, precise cuts may be necessary to ensure that glass panels fit properly and provide a seamless appearance.

Achieving tight tolerances in the laser cutting process requires precise control of the laser beam and the cutting process. It may also involve the use of specialized equipment and techniques, such as computer-controlled beam steering systems and high-precision focusing lenses.

Tight tolerances are important in laser cutting glass service because they ensure that the final product meets the required specifications and performs as intended.

14. How to ensure the precision of Laser Cutting Glass products?

There are several factors that can affect the precision of laser-cutting glass products. Here are a few steps you can take to ensure precision:

Use high-quality glass:

Using high-quality glass that is free of defects and has a consistent thickness can help ensure precision during the cutting process.

Use a high-quality laser cutter:

Investing in a high-quality laser cutter with a high-power laser and advanced optics can help ensure precise cuts.

Calibrate the laser cutter regularly:

Regularly calibrating the laser cutter can help ensure it is cutting accurately.

Use the correct cutting settings:

Adjusting the laser cutting settings, such as the laser power and cutting speed, to the appropriate levels for the specific type and thickness of glass being cut can help ensure precision.

Use proper cutting techniques:

Proper cutting techniques, such as using a low angle of incidence and making multiple passes to achieve the desired cut depth, can help ensure precision.

Inspect the finished product:

Inspecting the finished product for precision and making necessary adjustments can help ensure that the final product meets the desired specifications.

15. How to Find A Reliable Custom Laser Cutting Glass Parts Manufacturer in China?

Here are some tips for finding a reliable custom laser-cutting glass parts manufacturer in China:

Research the company:

Look for information about the company’s history, experience, and capabilities. Check for customer reviews and ratings to get an idea of the company’s reputation. HY has more than 12 years of working experience in the custom glass area.

Check for experience:

Look for a company that has experience working with custom laser cutting glass parts and has a proven track record of producing high-quality products.

Consider the company’s capabilities:

Look for a company that has the necessary equipment and technology to produce custom laser-cutting glass parts to your specifications. HY is your best choise.

Review the company’s customer service:

Look for a company that provides responsive and reliable customer service, including timely communication and support.

Consider the company’s pricing:

Look for a company that offers competitive pricing for your custom laser-cutting glass parts. HY can provide an amazing price for your custom glass project with keeping the premium quality.

16. How to cooperate with HY?

HY is a one-stop and high-quality custom glass laser cut factory that offers custom services according to your request.

HY is committed to achieving high-quality and accurate parts in a cost-effective manner.

At HY, our staff will be available anytime to facilitate you in case you require more information or have any questions.

HY requires some basic information and detailed size or 2D/3D design files of your custom glass parts to give you the perfect quality, performance, surface finish, tolerance, and price.

12+ years of field experience enabled us to handle any order from simple to complex in a very fast production time and competitive cost-effective price.

Most importantly, HY’s integrated approach to quality control is guarantee that your order is perfectly machined.

After a successful quote and agreement, we will start manufacturing your order asap.

Start Your Custom Glass Parts Project With Us Now

Want to save time and money on your custom glass parts project? Contact us now. Our factory provides high-quality precision custom glass products at very competitive prices and fast production times. We support free sample service.