Custom Sapphire optical Prisms

Optical prisms, transparent optical elements with polished flat surfaces for light refraction or reflection, find utility in beam deviation and image orientation adjustments.

In demanding applications across various industries, particularly in challenging environments like vacuum, high heat, and corrosive atmospheres, single crystal sapphire (Al2O3) prisms stand out. With an impressive surface hardness rating of 9 on the Mohs scale, high thermal conduction, and resistance to common chemical acids and alkalis, sapphire prisms excel, especially in laser systems.

The outstanding structural strength of sapphire allows the production of more compact prisms compared to those made from other materials. Sapphire demonstrates excellent transmittance within the range of 0.15 to 5.5 m, covering the UV to MWIR wavelength spectrum. This, coupled with good transmission characteristics in the visible and near-IR spectrum, makes sapphire an ideal choice for optical prisms in specialized fields such as space technology, where resistance to scratches and high temperatures is essential.

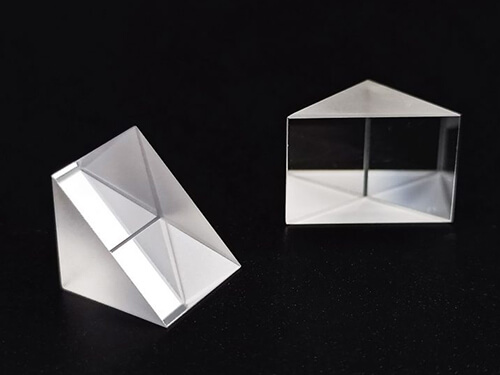

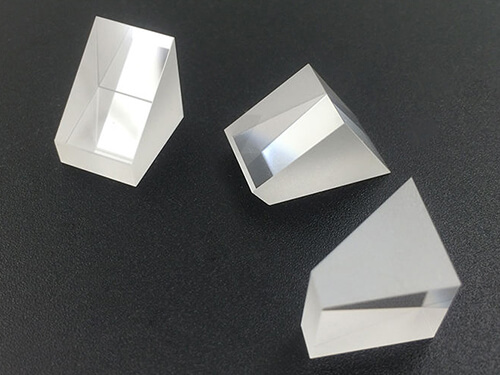

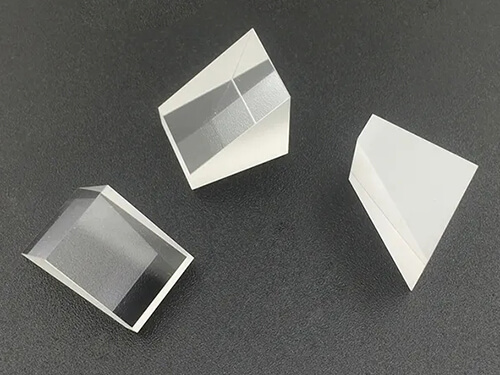

HY specializes in manufacturing custom sapphire prisms in various sizes and diameters tailored for optical applications in the visible, UV, and near-infrared spectra. Our offerings include customized prisms based on customer specifications, featuring diverse shapes such as right-angle prisms, 60° equilateral dispersing prisms, and other custom designs like dove prisms, Penta prisms, roof prisms, and rhomboid prisms.

What's optical prism?

Prisms play a crucial role in optics. The plane from which light emanates is termed the side, while the plane perpendicular to the side is referred to as the main section. The configuration of the main section encompasses various types, such as prisms, right-angle prisms, pentagonal prisms, and more. The main section of a prism is essentially a triangular shape with two refractive surfaces, characterized by the apex angle. The plane opposite the apex angle is known as the base.

As light traverses through the prism under the law of refraction, it undergoes a two-fold displacement towards the base. The angle between the emitted light and the incident light denoted as θ, is termed the deviation angle. This angle is influenced by the refractive index (n) and the incident angle (i) of the prism medium. When the incident angle is constant, different wavelengths exhibit distinct deviation angles, with violet having the largest angle and red the smallest in the visible light spectrum.

A prism, crafted through modeling, grinding, polishing, and other processes using solid optical glass, forms an angular glass block. Prisms serve two primary functions: dispersion and imaging. Distinctions among prism types are typically based on their properties and applications. The four main prism types and their features include dispersive prisms, deflection prisms, rotation prisms, and offset prisms. Dispersive prisms are tailored for use in dispersive light sources, while deflection, rotation, and offset prisms excel in high-quality imaging applications.

HY specializes in crafting various custom sapphire prisms, including sapphire right-angle prisms, sapphire triangle prisms, sapphire corner cube prisms, sapphire wedge prisms, sapphire penta prisms, sapphire dove prisms, and other bespoke designs.

Enhance your optical solutions with our cutting-edge Sapphire Prisms, meticulously crafted to surpass the most stringent standards. Each prism is uniquely fashioned from premium-grade sapphire and other high-quality optical materials, guaranteeing unparalleled durability and exceptional performance.

Contact us for a complimentary quote tailored to your custom sapphire prism needs.

The light transmission properties of sapphire are pretty good

As an ideal material for UV and IR applications, a sapphire stands out for its ability to transmit extensively into both UV and IR bands. Its thermal and chemical resilience allows it to withstand extreme plasmas and temperatures, surpassing the capabilities of other materials. Even under such conditions, a sapphire continues to transmit high-powered UV, visible, and IR light for extended periods without any degradation.

These unique properties position sapphire as the preferred material for UV/VIS/IR sensors, IR surveillance, reconnaissance, and broadband inspection equipment, especially in scenarios involving abrasives.

Sapphire emerges as the top choice for pyrometry, offering wide wavelength transmission while effectively isolating hot zones up to 2000°C from external room temperature observation. This makes sapphire the perfect material for furnaces and high-temperature processing equipment.

In the realm of medical and dental tools requiring UV sterilization, curing, and IR thermal processing, sapphire windows, and transparent tools shine in their performance.

Custom Sapphire Optical Parts Service With Easy

HY is a leading custom sapphire glass parts manufacturer specializing in the production of custom sapphire crystal parts. Our comprehensive solutions for custom sapphire optical parts fabrication encompass shaping, grinding, drilling, and polishing. Additionally, we offer coating solutions tailored to enhance and optimize performance across a wide spectrum of applications.

Backed by over 12 years of diverse experience, HY offers effective methods for polishing custom sapphire parts, ensuring low roughness, high surface quality, and precise surface accuracy.

We provide an extensive variety of custom sapphire optical parts, ranging from round and rectangular shapes to step configurations. Furthermore, we excel in crafting custom sapphire optics parts with diverse shapes and sizes, catering to specific requirements.

In HY, we turn complex to simple, following the 3 steps to start your custom sapphire optical parts project today:

1. Please Tell Us What You Need

Please tell us your specific needs, send a 2D 3D design drawing, details size, or a picture.

2. Get Solution & Quote

We will work on the best solution according to your requirements. The specific and best quotation will be sent within 24 hours.

3. Mass Production & Shipping

We will start mass production after getting your approval and deposit. Then we will handle the shipping for you. We are a one-stop custom sapphire optics parts solution manufacturer. You don’t need to worry about anything.

Sapphire Properties Reference Table

Artificial sapphire is a crystalline variant of corundum, also known as pure, single-crystal aluminum oxide (Al2O3). The distinct blend of its properties positions sapphire as the material of choice for demanding applications in mechanical, chemical, and optical fields. Below are the key features of sapphire glass.

- Chemical Formula:

- Names:

- Hardness:

- Class:

- Melting Point:

- Maximum Useful Temperature:

- Surface Quality:

- Axis Orientation:

- Young's Modulus:

- Tensile Strength:

- Flexural Strength:

- Modulus of Rigidity:

- Density (g/cm3):

- Transmission Range:

- Poisson's Ratio:

- Abbe Number (vd):

- Dimension Tolerance:

- Thickness Tolerance:

- Al2O3 (aluminum oxide)

- Corundum, Sapphire, Alpha-alumina

- 9 Moh's

- Hexagonal-scalenohedral

- 2053°C (3727°F)

- 2000°C

- 80/50, 60/40, 40/20, 20/10 (Scratch/Dig)

- C-Axis (C-Plane), M-Plane, A-Plane, R-Plane and Random

- 435

- 275 MPa to 400 MPa

- 480 MPa to 895 MPa

- 175 GPa

- 3.97

- 190nm to 5 microns

- 0.27 - 0.30

- 72.24

- ± 0.01-0.10mm

- ± 0.10mm

Get Your Custom Sapphire Project Into Production Today

HY is a reliable and high-quality custom sapphire glass parts manufacturer that provides precision custom sapphire parts. Our custom sapphire glass parts including sapphire tubes, sapphire lenses, sapphire rods, sapphire IPL light guides, micro sapphire rods, sapphire T-step windows, sapphire tapered rods, sapphire cones, sapphire wedges, sapphire optical prisms, sapphire substrate, sapphire watch glass, sapphire watch lens, sapphire single dome, sapphire double dome, ruby rod, ruby windows, ruby lens and so on. Competitive prices save you 20-60% purchasing cost. Contact us to get a free quote now.