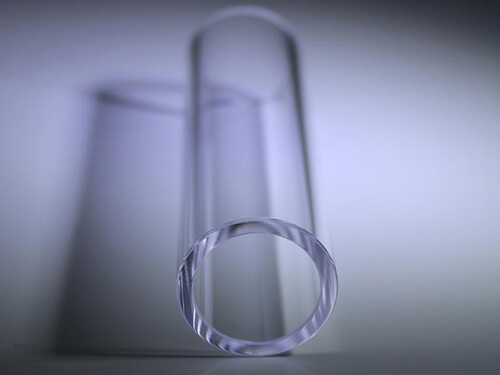

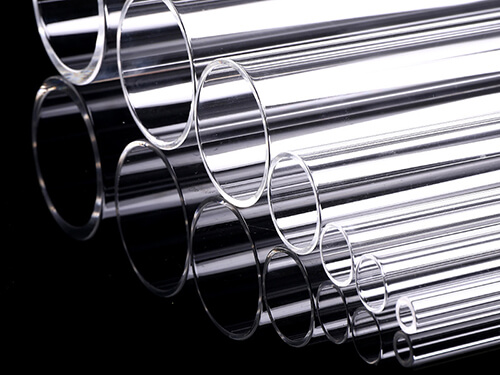

Custom Sapphire Tubes

Sapphire Tube is a type of transparent single-crystal alumina material renowned for its exceptional chemical stability and superior mechanical, thermal, and optical properties. When compared to commonly used transparent materials like glass and quartz, Sapphire Tube outperforms them significantly.

Sapphire boasts outstanding optical clarity, physical resilience, and chemical inertness. It stands as the hardest oxide crystal, retaining its strength and resistance even under elevated temperatures. Moreover, it exhibits a wide transmission spectrum, excellent electrical insulation properties, and efficient thermal conductivity, particularly at low temperatures.

Its remarkable attributes include high hardness, strength, and resistance to extreme temperatures, making it capable of withstanding harsh chemical environments such as fluorine plasma, acids, and alkaline solutions.

At HY, we specialize in crafting custom sapphire tubes tailored to meet diverse industrial and scientific requirements. Our products are engineered precisely according to customer specifications.

We welcome inquiries to discuss your specific sapphire needs.

Why do sapphire tubes have such high performance?

Sapphire tubes stand out as exceptional high-pressure vessels and conduits in numerous high-pressure systems. With their ability to withstand extreme pressures, they provide a secure means for observing and spectrally analyzing fluids and gases.

In hostile environments, sapphire tubes serve as protective enclosures for sensitive sensors, shielding them from pressure and mechanical stress.

Even under the harshest conditions, supported sapphire tubes maintain their structural integrity, remaining unchanged in shape at temperatures up to 2000°C while experiencing minimal reduction in mechanical performance. They excel in applications such as high-temperature combustion chambers, gas processing, and lamp construction.

With the highest temperature rating among optical materials, sapphire tubes offer unparalleled performance in both oxidizing and inert atmospheres.

Sapphire tubes exhibit extraordinary chemical resistance at elevated temperatures, withstanding the effects of most solvents, acids, and caustic substances, including molten metals. Only hot caustic salts can etch sapphire tubes, ensuring safe and chemically pure handling and processing of various chemicals.

Their exceptional chemical and bio-inert properties make sapphire tubes ideal for critical applications in medical, pharmaceutical, semiconductor, and other industries where purity and safety are paramount.

For over 12 years, HY has been at the forefront of fabricating sapphire tubes, offering a range of diameters and thicknesses tailored to high-temperature and high-pressure applications, including semiconductor manufacturing. Custom specifications and compositions are available upon request, along with innovative proprietary technologies.

Applications of custom sapphire tubes

Sapphire tubes emerge as prime materials for a diverse array of industrial applications, including semiconductor processing, testing, analytics, and lamp production. In testing and analytical contexts, they find utility in biological and chemical sample analysis, nuclear magnetic resonance spectroscopy, mass spectroscopy, thermo-optic temperature measurement, and inline petroleum processing analysis.

They serve various roles such as plasma containment, process gas injection, thermocouple protection, water treatment, and high-intensity lamp envelopes.

With its exceptional mechanical strength, sapphire tubes, especially those with thick walls, provide robust housing for sensors or lasers, shielding them from extreme pressures. Their polished outer and inner surfaces enable laser light emission and facilitate precise light measurement. These tubes are particularly suited for high-pressure systems and vacuum environments.

Sapphire tubes are highly preferred for plasma containment owing to their chemical inertness and corrosion resistance, ensuring no particle generation even under extreme plasma conditions.

Retaining their structural integrity at high temperatures and pressures, sapphire tubes excel as lamp materials, supporting UV, visible, and IR applications in hostile environments, thanks to their thermal stability, excellent thermal conductivity, and optical transparency.

HY offers a variety of sapphire tubes, including “as-grown,” finely ground, and polished options, catering to a wide range of applications. Customization options such as angled shapes, slots, holes, and bonded configurations are available to meet precise customer specifications.

Characteristics of sapphire tube

1. Remarkable transparency spanning wavelengths from 0.3 μm (UV) to 5 μm (IR). Polished sapphire tubes find applications in various analytical instruments requiring transmission of ultraviolet, visible, and infrared light.

2. Unparalleled hardness and scratch resistance render the sapphire tube virtually impervious to scratches, ensuring its integrity even in the harshest environments.

3. Boasting a high melting point of 2030°C, excellent thermal conductivity, and heat resistance, the sapphire tube proves ideal for high-temperature applications.

4. Demonstrating exceptional chemical stability and corrosion resistance, the sapphire tube’s innate inertness allows it to withstand aggressive chemicals.

5. Exhibiting outstanding electro-insulation properties, characterized by a stable dielectric constant, minimal dielectric loss, and excellent electrical insulation.

6. Possessing high strength, rigidity, abrasion resistance, heat resistance, corrosion resistance, and plasma resistance, making it an optimal choice for various demanding applications.

Benefits Of Sapphire Tube

Synthetic sapphire tubes offer a distinctive blend of superior optical, physical, and chemical properties.

As one of the hardest minerals, sapphire boasts exceptional scratch resistance, ranking 9 on the Mohs scale.

With a high melting point of 2030°C, coupled with remarkable thermal conductivity and heat resistance, sapphire proves ideal for demanding high-temperature applications.

Its outstanding chemical stability and resistance to corrosion equip it to thrive in harsh environments, including exposure to fluorine plasma, acids, and alkaline solutions. Furthermore, sapphire exhibits impressive transmission bandwidths, spanning from UV to IR at 0.15-5.5µm.

These remarkable attributes collectively provide a cost-effective solution for applications requiring the hardness, scratch resistance, corrosion resistance, heat resistance, and optical clarity offered by sapphire tubes.

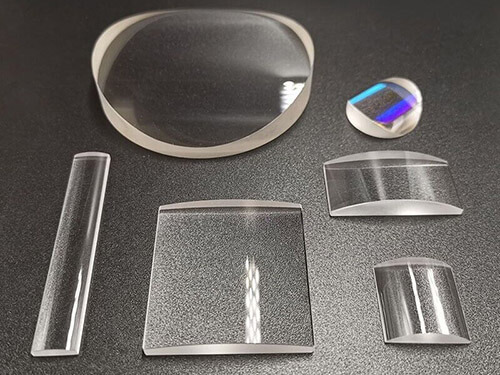

Custom Sapphire Optical Parts Service With Easy

HY is a leading custom sapphire glass parts manufacturer specializing in the production of custom sapphire crystal parts. Our comprehensive solutions for custom sapphire optical parts fabrication encompass shaping, grinding, drilling, and polishing. Additionally, we offer coating solutions tailored to enhance and optimize performance across a wide spectrum of applications.

Backed by over 12 years of diverse experience, HY offers effective methods for polishing custom sapphire parts, ensuring low roughness, high surface quality, and precise surface accuracy.

We provide an extensive variety of custom sapphire optical parts, ranging from round and rectangular shapes to step configurations. Furthermore, we excel in crafting custom sapphire optics parts with diverse shapes and sizes, catering to specific requirements.

In HY, we turn complex to simple, following the 3 steps to start your custom sapphire optical parts project today:

1. Please Tell Us What You Need

Please tell us your specific needs, send a 2D 3D design drawing, details size, or a picture.

2. Get Solution & Quote

We will work on the best solution according to your requirements. The specific and best quotation will be sent within 24 hours.

3. Mass Production & Shipping

We will start mass production after getting your approval and deposit. Then we will handle the shipping for you. We are a one-stop custom sapphire optics parts solution manufacturer. You don’t need to worry about anything.

Sapphire Properties Reference Table

Artificial sapphire is a crystalline variant of corundum, also known as pure, single-crystal aluminum oxide (Al2O3). The distinct blend of its properties positions sapphire as the material of choice for demanding applications in mechanical, chemical, and optical fields. Below are the key features of sapphire glass.

- Chemical Formula:

- Names:

- Hardness:

- Class:

- Melting Point:

- Maximum Useful Temperature:

- Surface Quality:

- Axis Orientation:

- Young's Modulus:

- Tensile Strength:

- Flexural Strength:

- Modulus of Rigidity:

- Density (g/cm3):

- Transmission Range:

- Poisson's Ratio:

- Abbe Number (vd):

- Dimension Tolerance:

- Thickness Tolerance:

- Al2O3 (aluminum oxide)

- Corundum, Sapphire, Alpha-alumina

- 9 Moh's

- Hexagonal-scalenohedral

- 2053°C (3727°F)

- 2000°C

- 80/50, 60/40, 40/20, 20/10 (Scratch/Dig)

- C-Axis (C-Plane), M-Plane, A-Plane, R-Plane and Random

- 435

- 275 MPa to 400 MPa

- 480 MPa to 895 MPa

- 175 GPa

- 3.97

- 190nm to 5 microns

- 0.27 - 0.30

- 72.24

- ± 0.01-0.10mm

- ± 0.10mm

Get Your Custom Sapphire Project Into Production Today

HY is a reliable and high-quality custom sapphire glass parts manufacturer that provides precision custom sapphire parts. Our custom sapphire glass parts including sapphire tubes, sapphire lenses, sapphire rods, sapphire IPL light guides, micro sapphire rods, sapphire T-step windows, sapphire tapered rods, sapphire cones, sapphire wedges, sapphire optical prisms, sapphire substrate, sapphire watch glass, sapphire watch lens, sapphire single dome, sapphire double dome, ruby rod, ruby windows, ruby lens and so on. Competitive prices save you 20-60% purchasing cost. Contact us to get a free quote now.