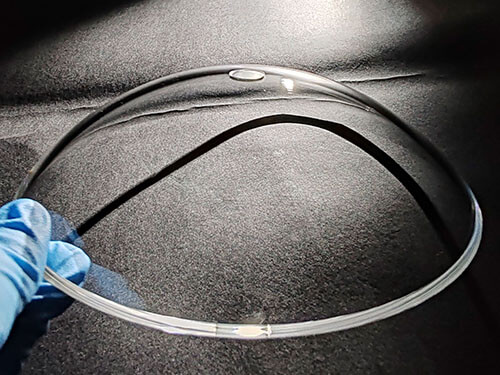

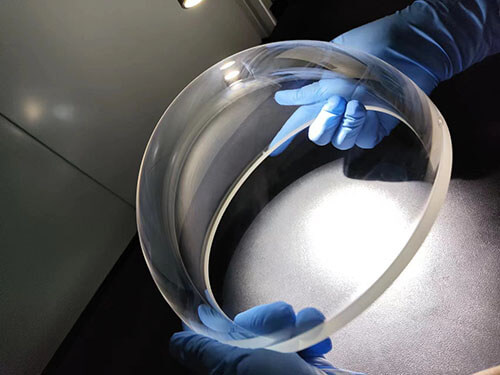

Custom Spherical Sapphire Dome

Spherical sapphire dome is a curved hemispherical or dome-shaped piece made from synthetic sapphire, a highly durable and scratch-resistant material. Sapphire domes are commonly used in various high-performance applications due to their exceptional strength, hardness, optical clarity, and resistance to thermal and chemical damage.

The dome shape allows for broader viewing angles, making it ideal in situations where wide visibility is essential. It’s often used in high-tech applications like watchmaking, scientific instruments, aerospace, and medical devices. The dome shape allows for a wide field of view or a strong structural design, depending on the application.

The spherical dome’s shape offers additional mechanical strength, distributes stress more evenly, and minimizes refraction issues that could distort visibility at the edges. It makes creating optical lenses with broader field coverage and minimal distortion easier, particularly under challenging environmental conditions.

We have rich experience in manufacturing custom optical sapphire domes. We can produce a variety of custom sapphire domes, including sapphire hemispherical domes, sapphire hyper-hemispherical domes, kerfs sapphire domes, spherical sapphire domes, aspheric sapphire domes, sapphire domes (Sapphire fairing radome), U-shape sapphire domes, conformal sapphire domes, and special–shaped sapphire hyper-hemisphere dome.

The diameter of HY custom sapphire domes can be manufactured up to Φ390mm.

Contact us to get a free quote for your custom spherical sapphire dome projects.

The Advantage Of spherical sapphire dome

1. Exceptional Durability and Scratch Resistance

1). Material Strength: Sapphire is extremely hard (9 on the Mohs scale, just below the diamond), making it highly resistant to scratching and wear. This is crucial for applications exposed to abrasive or corrosive environments.

2). Impact Resistance: The spherical shape helps distribute external stresses more evenly across the surface, reducing the chance of cracking or breaking under pressure.

2. High Optical Clarity and Transparency

1). Visibility: Sapphire is transparent to a wide range of wavelengths, including visible and some infrared. This makes it ideal for applications where optical clarity is essential, such as in camera lenses, sensors, and viewing windows.

2). Minimal Distortion: The curvature of a spherical dome reduces distortion, especially at the edges, ensuring a clear view from various angles.

3. Broad Field of View

The dome shape allows for a wide viewing angle, making it ideal for cameras, sensors, and other optical devices that need to capture or monitor a broad field without obstruction or edge distortion.

4. Pressure Resistance

1). Even Stress Distribution: The curved, dome shape disperses pressure more evenly than flat surfaces. This makes spherical sapphire domes well-suited for use in high-pressure environments, like deep-sea submersibles and aerospace equipment.

2). Temperature and Chemical Stability: Sapphire is highly resistant to thermal shock and chemical corrosion, so it performs well under extreme conditions and in diverse environments.

5. Resistance to Thermal Expansion

Minimal Thermal Deformation: Sapphire has a low coefficient of thermal expansion, meaning it changes shape very little under temperature fluctuations. This property is vital in applications requiring high precision or exposure to rapid temperature changes, such as aerospace or scientific instruments.

6. Enhanced Aesthetic Appeal

In high-end watches and luxury products, a sapphire dome offers a sleek, polished look that’s resistant to scratches, enhancing both the durability and aesthetics of the item.

7. Longevity and Low Maintenance

Sapphire’s resistance to scratching, chemical degradation, and impact means it requires minimal maintenance and retains its optical clarity and structural integrity over time, even in challenging conditions.

Applications of spherical sapphire dome

Sapphire is a highly durable and scratch-resistant material, second in hardness only to diamond, which makes it ideal for harsh environments. The transparency and clarity of sapphire also make it excellent for optical applications, where high visibility and durability are crucial. The key uses of spherical sapphire domes are as below:

1. Optical Sensors and Cameras: Used as protective covers for sensors and lenses, especially in environments that are harsh or exposed to debris, extreme temperatures, or underwater.

2. Watches and Instruments: Sapphire domes serve as crystal covers on luxury watches, preventing scratches and ensuring long-lasting transparency, providing a scratch-resistant, clear view of the dial.

3. Aerospace and Defense: Protect sensors, cameras, and other sensitive equipment in aerospace, military, and underwater applications. Certain aerospace applications use sapphire domes for high-strength optical windows due to their ability to withstand high stress, temperature changes, and abrasive particles.

4. Scientific Equipment: Used in specialized microscopes and high-precision instruments due to their optical clarity and durability.

5. Optics and Cameras: In devices exposed to tough environments, such as underwater cameras, aerospace cameras, or industrial equipment, sapphire domes protect delicate optical components while maintaining clarity.

6. Scientific Instruments: Sapphire domes are used for pressure windows, particularly in extreme environments, like deep-sea submersibles or pressure chambers, where visibility and strength are essential.

Custom Sapphire Optical Parts Service With Easy

HY is a leading custom sapphire glass parts manufacturer specializing in the production of custom sapphire crystal parts. Our comprehensive solutions for custom sapphire optical parts fabrication encompass shaping, grinding, drilling, and polishing. Additionally, we offer coating solutions tailored to enhance and optimize performance across a wide spectrum of applications.

Backed by over 12 years of diverse experience, HY offers effective methods for polishing custom sapphire parts, ensuring low roughness, high surface quality, and precise surface accuracy.

We provide an extensive variety of custom sapphire optical parts, ranging from round and rectangular shapes to step configurations. Furthermore, we excel in crafting custom sapphire optics parts with diverse shapes and sizes, catering to specific requirements.

In HY, we turn complex to simple, following the 3 steps to start your custom sapphire optical parts project today:

1. Please Tell Us What You Need

Please tell us your specific needs, send a 2D 3D design drawing, details size, or a picture.

2. Get Solution & Quote

We will work on the best solution according to your requirements. The specific and best quotation will be sent within 24 hours.

3. Mass Production & Shipping

We will start mass production after getting your approval and deposit. Then we will handle the shipping for you. We are a one-stop custom sapphire optics parts solution manufacturer. You don’t need to worry about anything.

Sapphire Properties Reference Table

Artificial sapphire is a crystalline variant of corundum, also known as pure, single-crystal aluminum oxide (Al2O3). The distinct blend of its properties positions sapphire as the material of choice for demanding applications in mechanical, chemical, and optical fields. Below are the key features of sapphire glass.

- Chemical Formula:

- Names:

- Hardness:

- Class:

- Melting Point:

- Maximum Useful Temperature:

- Surface Quality:

- Axis Orientation:

- Young's Modulus:

- Tensile Strength:

- Flexural Strength:

- Modulus of Rigidity:

- Density (g/cm3):

- Transmission Range:

- Poisson's Ratio:

- Abbe Number (vd):

- Dimension Tolerance:

- Thickness Tolerance:

- Al2O3 (aluminum oxide)

- Corundum, Sapphire, Alpha-alumina

- 9 Moh's

- Hexagonal-scalenohedral

- 2053°C (3727°F)

- 2000°C

- 80/50, 60/40, 40/20, 20/10 (Scratch/Dig)

- C-Axis (C-Plane), M-Plane, A-Plane, R-Plane and Random

- 435

- 275 MPa to 400 MPa

- 480 MPa to 895 MPa

- 175 GPa

- 3.97

- 190nm to 5 microns

- 0.27 - 0.30

- 72.24

- ± 0.01-0.10mm

- ± 0.10mm

Get Your Custom Sapphire Project Into Production Today

HY is a reliable and high-quality professional custom sapphire glass parts manufacturer that provides precision custom sapphire parts service. Our custom sapphire crystal glass parts including sapphire windows, sapphire IPL light guides, sapphire optical prisms, custom sapphire domes, sapphire hemispherical domes, sapphire hyper-hemispherical domes, kerfs sapphire domes, spherical sapphire domes, aspheric sapphire domes, sapphire domes (Sapphire fairing radome), U-shape sapphire domes, conformal sapphire domes, special–shaped sapphire hyper-hemisphere dome, sapphire tubes, sapphire lenses, sapphire rods, micro sapphire rods, sapphire T-step windows, sapphire tapered rods, sapphire cones, sapphire wedges, sapphire substrate, sapphire watch glass, sapphire watch lens, sapphire single dome, sapphire double dome, ruby rod, ruby windows, ruby lens and so on. Competitive prices save you 40-80% purchasing cost. Contact us to get a free quote now.