Drilling Service

High-quality custom glass & sapphire glass drilling service supplier at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass drilling service?

Glass drilling service refers to the process of creating precise holes or perforations in glass surfaces. Glass drilling is required for various applications where holes are needed in glass panels, such as for mounting hardware, plumbing fixtures, electrical wiring, or decorative purposes.

Glass drilling is a delicate process that requires specialized tools and techniques to prevent the glass from cracking or shattering. The drilling is typically performed using diamond-tipped drill bits or diamond core drills. Diamond is used due to its hardness and ability to cut through glass effectively. The drill bits are specifically designed to create clean and precise holes in glass without damaging the surrounding area.

HY manufacturer specializes in providing custom OEM drilling services for glass parts and sapphire parts. Our factory produces premium glass and sapphire components at factory-direct prices.

Contact us to get a free quote for your custom glass & sapphire glass parts.

What are the properties of Glass & Sapphire Glass drilling?

Glass & sapphire glass drilling is a specialized process that introduces holes into glass surfaces. While the properties of the glass & sapphire glass itself are not altered by drilling, there are certain considerations and properties associated with the drilling process:

Precision

Glass drilling requires high precision to create clean and accurate holes in the desired locations. Skilled operators and specialized equipment are used to ensure precise positioning and drilling.

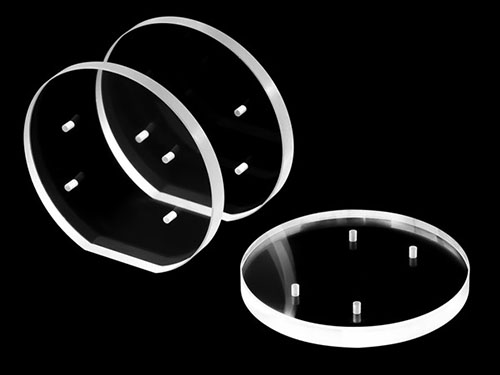

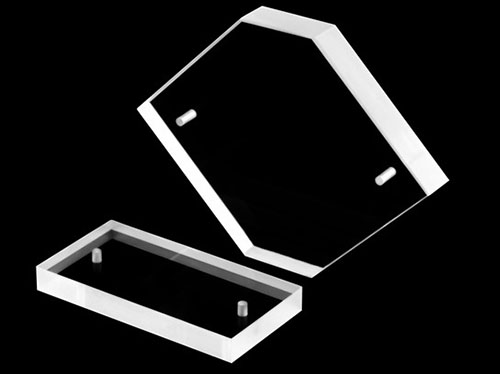

Hole Size and Shape

Glass drilling can produce holes of various sizes and shapes, depending on the requirements of the application. The diameter and depth of the hole can be customized to suit specific needs, allowing for versatility in design and functionality.

Clean Edges

When performed correctly, glass drilling results in clean and smooth edges around the hole. This is essential for both functional and aesthetic purposes, ensuring that the drilled hole does not compromise the structural integrity or appearance of the glass.

Hole Integrity

Glass drilling should not weaken the structural integrity of the glass panel. When performed properly, the drilled hole maintains the overall strength and safety properties of the glass, including its resistance to breakage and impact.

Surface Finish

The drilling process can leave slight imperfections on the glass surface around the hole, such as micro-cracks or roughness. These imperfections can be minimized or eliminated through post-drilling processes like polishing or edge finishing, ensuring a smooth and visually appealing result.

Types of glass & sapphire glass drilling?

There are several types of glass & sapphire glass drilling techniques used based on the specific requirements of the project and the characteristics of the glass & sapphire glass being drilled. Here are some common types of glass drilling:

Conventional Drilling

Conventional drilling involves using diamond-tipped drill bits to create holes in glass. This method is suitable for drilling standard glass thicknesses and is commonly used for general applications.

Core Drilling

Core drilling, also known as diamond core drilling, is used to create larger-diameter holes in thick glass panels. This technique utilizes a hollow cylindrical drill bit with diamond-impregnated edges to remove a core of glass material, leaving a clean hole.

Countersink Drilling

Countersink drilling is a technique used to create a hole with a tapered edge or a wider opening at the top. This allows for the flush insertion of screws or bolts, providing a neat and aesthetically pleasing finish. Countersink drilling is often used in applications where fasteners need to be concealed.

Trepanning

Trepanning is a specialized drilling technique used to create larger holes or openings in glass panels. It involves drilling a series of overlapping smaller holes along the desired perimeter and then removing the central material to achieve the desired hole size or shape.

Step Drilling

Step drilling involves creating holes with multiple diameters or steps in a single drilling operation. This technique is commonly used when different components or fixtures of varying sizes need to be accommodated within a single hole.

Laser Drilling

Laser drilling is a precise and non-contact drilling method that uses laser energy to vaporize or melt the glass, creating a hole. It is often used for highly specialized applications requiring extremely precise and controlled hole dimensions, such as micro-drilling or drilling in fragile or sensitive glass materials.

What are the benefits of glass & sapphire glass drilling?

Customization

Glass drilling allows for precise customization of glass panels to accommodate specific requirements. It enables the creation of holes in various sizes, shapes, and locations, providing flexibility in design and functionality.

Installation of Hardware and Fixtures

Glass drilling facilitates the installation of hardware, fixtures, and components onto glass surfaces. It allows for the attachment of hinges, handles, knobs, brackets, and other accessories, enabling the integration of glass panels into functional structures or systems.

Functionality

Glass drilling enables the incorporation of functional elements into glass panels. This includes routing holes for plumbing fixtures, electrical wiring, or ventilation systems. It ensures the seamless integration of glass in applications requiring connectivity, such as glass sinks, lighting fixtures, or display cabinets.

Versatility

By introducing holes, glass drilling expands the versatility of glass as a building material. It enables the incorporation of glass panels in diverse applications, such as architectural designs, interior decorations, furniture, shower enclosures, display cases, partitions, and more.

Efficiency in Manufacturing

For glass manufacturers, drilling capabilities streamline production processes by enabling the creation of pre-drilled glass panels. This reduces the need for on-site drilling or secondary processing, optimizing manufacturing efficiency and lead times.

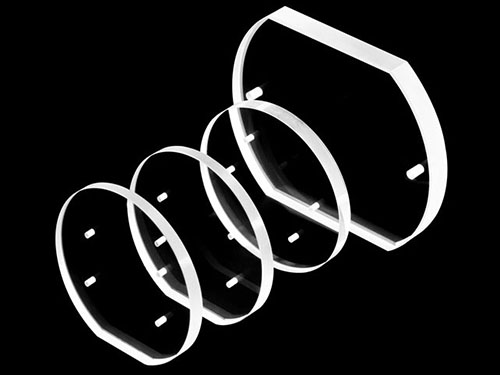

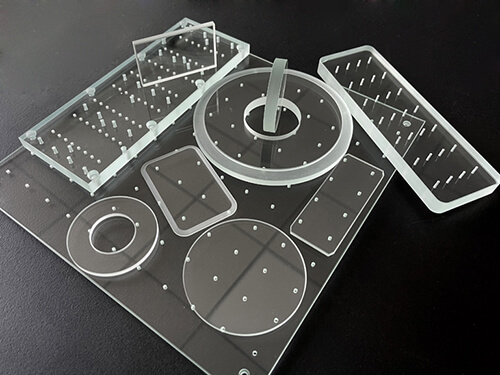

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & Sapphire Glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.