Edging Grinding Service

Precision custom glass & sapphire glass edging grinding service factory at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass edging grinding service?

Glass & sapphire glass edging grinding service refers to the process of shaping and smoothing the edges of glass panels to achieve a desired finish. The purpose of this service is to enhance the aesthetics, safety, and functionality of the glass by removing sharp or uneven edges that may pose a risk of injury or affect the glass’s usability.

HY factory specializes in providing glass & sapphire edging grinding services. Our factory produces premium glass and sapphire components at factory-direct prices.

Contact us to get a free quote for your custom glass & sapphire glass parts.

What are the properties of glass & sapphire glass edging grinding?

Glass & sapphire glass edging grinding is a process that modifies the edges of glass & sapphire glass panels to achieve specific properties and characteristics. Here are some key properties associated with glass edging grinding:

Smoothness

The primary goal of glass & sapphire glass edging grinding is to create smooth and even edges on the glass & sapphire glass panel. The grinding process removes any sharp or rough areas, resulting in edges that are comfortable to touch and handle. This property is crucial for applications where human contact is likely, as it reduces the risk of cuts or injuries.

Safety

By eliminating sharp edges, glass & sapphire glass edging grinding enhances the safety of the glass & sapphire glass panels. It reduces the likelihood of accidental cuts or injuries during installation, handling, or use. This is particularly important for applications such as doors, windows, furniture, or any situation where there is frequent human interaction with the glass.

Customization

Glass & sapphire glass edging grinding allows for customization of the glass & sapphire glass edges to meet specific requirements. Different edge profiles can be achieved, such as flat, beveled, chamfered, rounded, or decorative edges, depending on the desired design and functionality. This customization adds versatility and enables the glass & sapphire glass to seamlessly integrate into various architectural or design concepts.

Durability

The grinding process can strengthen the edges of the glass & sapphire glass panel, increasing its resistance to chipping or cracking. By removing any weak or vulnerable areas, the glass & sapphire glass becomes more durable and less prone to damage.

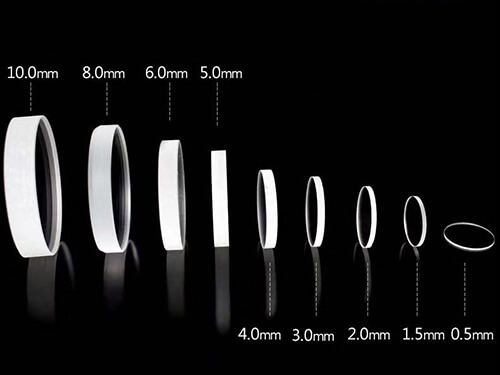

Compatibility

Glass & sapphire glass edging grinding can be performed on different types of glass & sapphire glass. It is compatible with various glass thicknesses, allowing for a wide range of applications.

Aesthetics

Edging grinding can significantly improve the visual appeal of glass & sapphire glass panels. By creating clean, finished edges, the glass & sapphire glass looks more polished and professional. This enhances the overall aesthetics of the glass & sapphire glass, making it more attractive for various applications.

Types of glass & sapphire glass edging grinding?

There are several types of glass & sapphire glass edging grinding techniques used to achieve different edge profiles and finishes. The specific type of edging grinding applied depends on the desired aesthetics, functionality, and project requirements. Here are some common types of glass & sapphire glass edging grinding:

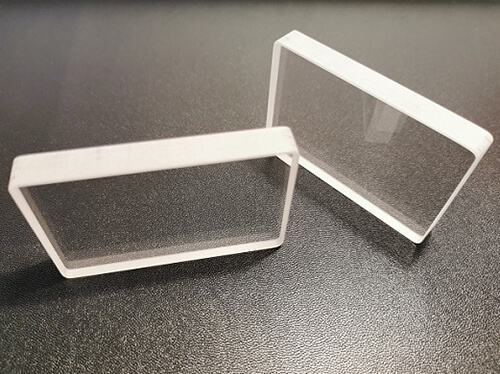

Flat Edging

Flat edging involves grinding the edges of the glass & sapphire glass to create a flat and smooth finish. This is the simplest and most common type of edging grinding, resulting in straight and even edges.

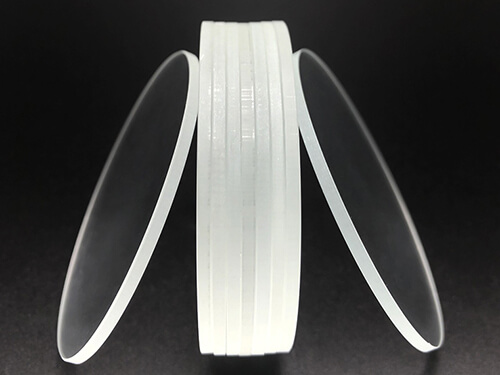

Pencil Edging

Pencil edging, also known as C-edge or radius edge, involves grinding the edges of the glass & sapphire glass to create a slight curve or rounded profile. The resulting edges resemble the shape of a pencil or a quarter circle. Pencil edging adds a softer and more decorative touch to the glass & sapphire glass panels.

Bevel Edging

Bevel edging creates a sloping or angled edge along the perimeter of the glass & sapphire glass. This is achieved by grinding and polishing the edge at a specific angle, typically ranging from 15 to 45 degrees. Bevel edging imparts an elegant and decorative look to the glass & sapphire glass, creating a sleek and sophisticated appearance.

Seamed Edging

Seamed edging involves grinding and smoothing the edges of the glass & sapphire glass to remove any sharp burrs or rough areas. However, unlike other types of edging, seamed edging does not create a specific profile or decorative shape. It focuses primarily on safety and functionality by ensuring that the edges are smooth and comfortable to touch.

Triple Pencil Edging

Triple pencil edging is a more intricate variation of pencil edging. It involves grinding three rounded profiles along the edge of the glass & sapphire glass, creating a triple-tiered effect. This type of edging adds a unique and eye-catching design element to the glass & sapphire glass.

OGEE Edging

OGEE edging creates an S-shaped or wave-like profile along the edge of the glass & sapphire glass. This type of edging is commonly used for decorative purposes, adding a distinctive and visually appealing element to the glass & sapphire glass panels.

What are the benefits of glass & sapphire glass edging grinding?

Glass & sapphire glass edging grinding enhances the safety, durability, functionality, and aesthetics of glass & sapphire glass products, making them suitable for diverse applications while providing a superior user experience. Glass edging grinding offers several benefits, including:

Smoother Edges

Glass & sapphire glass edging grinding helps to create smooth, rounded edges on glass surfaces. This is particularly important for safety reasons, as sharp edges can be hazardous and prone to causing injuries. Smooth edges also enhance the aesthetic appeal of the glass & sapphire glass.

Improved Safety

By eliminating sharp edges and reducing the risk of chipping, glass & sapphire glass edging grinding enhances the safety of glass & sapphire glass products. It minimizes the potential for accidental cuts or injuries, making the glass more user-friendly and suitable for various applications.

Functionality

Edging grinding can modify the shape and profile of the glass & sapphire glass edges to suit specific functional requirements. For example, the edges can be beveled, chamfered, or rounded to facilitate installation, provide a better fit, or accommodate hardware and accessories.

Enhanced Strength and Durability

The grinding process removes any imperfections or micro-cracks present on the glass & sapphire glass edges, strengthening them and increasing their durability. This is particularly relevant for tempered glass, as the edges are more vulnerable to damage during the tempering process. Properly edged glass is less likely to break or shatter under stress.

Improved Fit and Functionality

Glass edging grinding ensures precise dimensions and accurate angles, enabling glass & sapphire glass panels or sheets to fit seamlessly into their designated spaces or frames. This is crucial in applications such as windows, doors, and display cases, where a proper fit is essential for functionality and aesthetics.

Versatile Design Options

Glass & sapphire glass edging grinding opens up a wide range of design possibilities. The process allows for the creation of various edge profiles, including beveled edges, pencil edges, flat edges, or custom-designed shapes. This versatility enables glass & sapphire glass fabricators to meet specific design requirements and achieve desired visual effects.

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & Sapphire Glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.