Frosted Service

Precision OEM custom glass & sapphire glass parts frosted service at competitive price

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass frosted processing?

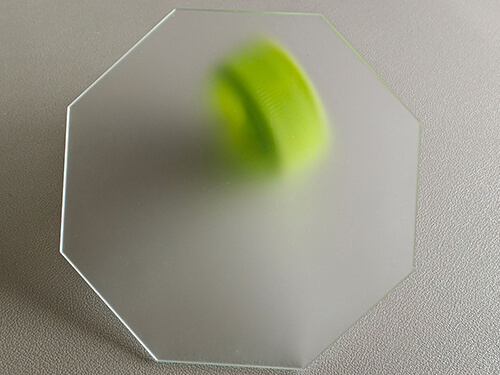

The term “sapphire glass and glass frosted service” typically refers to a process of treating glass to create a frosted or translucent appearance.

Frosted glass is glass that has been rendered opaque or diffused, reducing its transparency while still allowing light to pass through.

This effect is achieved by either etching or sandblasting the surface of the glass.

Etched glass frosted service involves using an abrasive material, such as acid or a chemical etching compound, to create a frosted pattern on the glass.

The surface of the glass is covered with a stencil or protective coating, leaving the desired design exposed.

The etching substance is then applied, which erodes the exposed glass, creating a frosted effect.

Sandblasted glass frosted service involves using a high-pressure stream of sand or similar abrasive material to bombard the glass surface.

The sand particles effectively roughen the glass, resulting in a frosted appearance.

What are the properties of glass frosted?

Glass that has been frosted or given a frosted appearance possesses several distinct properties. Here are some key properties associated with frosted glass:

Opacity

Frosted glass is characterized by its opaque or translucent appearance. It diffuses light and obscures visibility, providing privacy and reducing glare while still allowing some light transmission. The level of opacity can vary depending on the specific frosted technique used and the desired effect.

Light Diffusion

Frosted glass scatters and diffuses light, creating a soft and even distribution of light. This property makes frosted glass an attractive choice for applications where diffused or muted lighting is desired, such as in decorative fixtures, privacy windows, or lampshades.

Privacy

Frosted glass provides privacy by obscuring views while still allowing light transmission. It is commonly used in applications where maintaining privacy is important, such as in bathrooms, office partitions, or conference rooms.

Versatility

Frosted glass can be applied to various types of glass, including clear glass, tinted glass, or low-iron glass. It can be used in different thicknesses and sizes, allowing for versatility in design and application. Frosted glass can be utilized in windows, doors, partitions, shower enclosures, furniture, decorative glass panels, and more.

Durability

Frosted glass maintains the inherent strength and durability of the base glass material. Depending on the specific type of glass used, frosted glass can exhibit properties such as scratch resistance, impact resistance, and thermal stability, making it suitable for various indoor and outdoor applications.

Types of glass frosted?

There are different types of glass frosted finishes, each achieved through various techniques and processes. Here are some common types of glass frosted finishes:

Sandblasted Frosted Glass

Sandblasted glass is created by using abrasive materials, such as sand or aluminum oxide, to etch the surface of the glass. This process creates a uniformly frosted appearance with a slightly textured feel. Sandblasted frosted glass provides a high level of opacity while allowing light transmission.

Acid Etched Frosted Glass

Acid etching involves applying an acid solution, typically hydrofluoric acid, to the glass surface. The acid reacts with the glass, removing a thin layer and creating a frosted appearance. Acid etched frosted glass offers a smooth, satin-like finish and provides varying levels of opacity, depending on the duration of the etching process.

What are the benefits of glass frosted?

Glass with a frosted finish offers several benefits in various applications. Here are some key benefits of using glass with a frosted appearance

Diffused Light

Frosted glass scatters and diffuses light, creating a soft and even distribution of illumination. This property makes frosted glass an excellent choice for applications where diffused or muted lighting is desired, such as in decorative fixtures, lampshades, or backlit signs. It helps to reduce glare and create a more gentle, pleasing light ambiance.

Durability

Frosted glass retains the inherent durability and strength of the base glass material. Depending on the specific type of glass used, frosted glass can exhibit properties such as scratch resistance, impact resistance, and thermal stability, making it suitable for both indoor and outdoor applications.

Versatility

Frosted glass is versatile and can be used in numerous applications. It can be incorporated into windows, doors, partitions, shower enclosures, cabinets, shelving, furniture, and more. Frosted glass can be applied to different glass types, including clear glass, tinted glass, or low-iron glass, allowing for design flexibility and integration into various architectural and interior design styles.

Light Control

Frosted glass allows for light control by reducing harsh glares and minimizing direct sunlight. It can help to create a more comfortable and visually pleasing environment by diffusing and softening the incoming light. This property is particularly beneficial in areas where excessive brightness or direct sunlight can cause discomfort or hinder productivity.

Privacy

Frosted glass provides privacy by obscuring views while still allowing light transmission. It is commonly used in areas where maintaining privacy is essential, such as in bathrooms, office partitions, meeting rooms, or residential spaces. Frosted glass can create a sense of separation and confidentiality without completely blocking natural light.

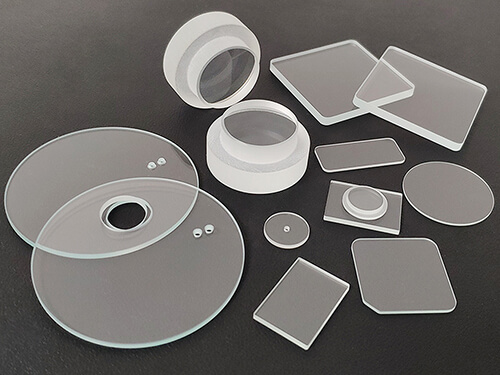

Custom Glass And Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

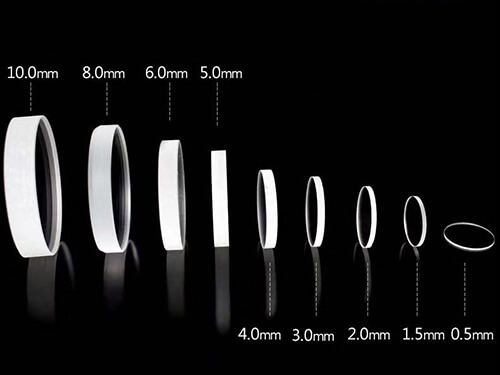

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get A Quote For Your Custom Glass And Sapphire Glass Parts

Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.