Custom Frosted glass Service

High-quality custom Frosted glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is Frosted glass?

Frosted glass is a type of glass that has been treated to have a rough, opaque surface that scatters light rather than transmitting it clearly.

The process of frosting glass involves etching the surface of the glass with an abrasive material or applying an acid solution to create a texture that diffuses the light passing through it.

Frosted glass is often used for privacy purposes because it obscures the view of objects behind it. It is commonly used for shower doors, bathroom windows, and office partitions.

Frosted glass can also be used for decorative purposes, such as creating patterns or designs on glass panels or windows.

Frosted glass can be made from different types of glass, including tempered glass, laminated glass, and even regular annealed glass.

It can be produced in various levels of opacity, from lightly frosted to heavily frosted, depending on the desired level of privacy and light diffusion.

What are the properties of Frosted glass?

Chemical Properties

Frosted glass is resistant to most chemicals, including acids, bases, and solvents. It is also non-porous, which makes it less susceptible to staining or discoloration.

Mechanical Properties

Frosted glass has similar mechanical properties to regular glass. It is strong and durable, but it is also brittle and can break under impact or pressure.

Electrical Properties

Frosted glass is an insulator, which means it does not conduct electricity. This property makes it safe to use in electrical applications, such as light fixtures or switches.

Thermal Properties

Frosted glass has similar thermal properties to regular glass. It is a good insulator and can withstand moderate temperature changes without cracking or breaking. However, sudden and extreme temperature changes can cause frosted glass to crack.

Optical Properties

Frosted glass scatters light, which makes it opaque and reduces the transparency of the glass. This property makes frosted glass ideal for privacy purposes, but it also reduces the amount of light that passes through it.

Optical Properties

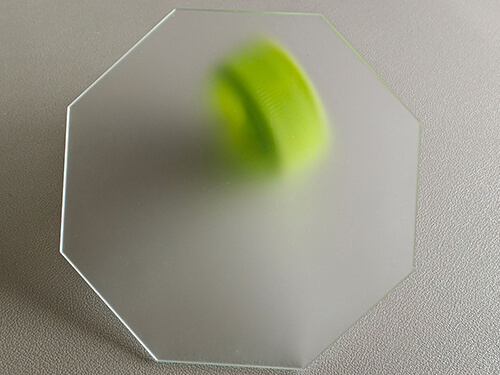

Frosted glass has a rough, textured surface that feels slightly abrasive to the touch. It is also slightly more opaque than regular glass, which gives it a frosted or cloudy appearance. Frosted glass is available in various thicknesses, sizes, and levels of opacity, depending on the desired application.

Types of Frosted Glass?

There are several types of frosted glass, each with its own unique characteristics and applications. Here are some of the most common types:

Acid-etched Frosted Glass

This type of frosted glass is created by applying an acid solution to the surface of the glass. The acid removes a thin layer of glass, creating a rough, frosted texture. Acid-etched frosted glass is highly durable and has a uniform, matte finish that is ideal for decorative applications.

Sandblasted Frosted Glass

Sandblasted frosted glass is created by blasting sand or other abrasive particles at the surface of the glass. This process creates a texture that diffuses light, giving the glass a frosted appearance. Sandblasted frosted glass is available in a range of patterns and designs and is commonly used for privacy screens, partitions, and decorative windows.

Double-sided Frosted Glass

Double-sided frosted glass has a frosted texture on both sides of the glass, creating a uniform, opaque appearance. This type of frosted glass is ideal for applications where privacy is a concern, such as bathroom windows or shower enclosures.

Printed Frosted Glass

Printed frosted glass is created by printing a pattern or design onto the surface of the glass before frosting it. This process allows for custom designs and graphics to be applied to the glass, making it ideal for branding, signage, or decorative applications.

Colored Frosted Glass

Colored frosted glass is created by adding a colored film or coating to the surface of the glass before frosting it. This process allows for a range of colors and shades to be applied to the glass, making it ideal for decorative applications where a specific color is desired.

Applications of frosted glass cutting service?

Custom frosted glass plates and lenses provide a versatile solution for creating diffused light and privacy in a variety of applications. Custom frosted glass plates and lenses can be used in a variety of applications that require diffused light or privacy. Here are some common applications of custom frosted glass plates and lenses:

Lighting Fixtures

Custom frosted glass plates and lenses are commonly used in lighting fixtures to create a soft, diffused light. Frosted glass plates and lenses can be used to create custom-sized diffusers for pendant lights, wall sconces, and ceiling fixtures.

Photography and Film Lighting

Custom frosted glass plates and lenses are often used in photography and film lighting to create a soft, diffused light that is free from harsh shadows. Frosted glass plates and lenses can be used to create custom-sized diffusers for studio lights, camera filters, and other lighting equipment.

Medical Equipment

Custom frosted glass plates and lenses are used in medical equipment such as microscope lenses, surgical instruments, and x-ray machines. Frosted glass plates and lenses provide a diffused light that is less harsh on the eyes and can help to reduce glare.

Electronic Displays

Custom frosted glass plates and lenses can be used in electronic displays, such as LED screens and digital signage, to create a diffused light that is easy on the eyes and reduces glare. Frosted glass plates and lenses can also be used to create privacy screens for computer monitors and other electronic devices.

Optical Filters

Custom frosted glass plates and lenses can be used as optical filters to control the amount and direction of light that passes through them. Frosted glass filters are commonly used in laser optics, telescopes, and other optical instruments.

What advantages of custom Frosted glass parts?

Frosted glass, also known as etched glass, is a type of glass that has a matte, translucent surface. It is created by either sandblasting or acid-etching a clear sheet of glass, which creates a surface that diffuses light and obscures visibility. Frosted glass is a versatile material that can enhance privacy, improve aesthetics, and provide safety and durability. Here are some advantages of frosted glass:

Durability

Frosted glass is tempered, which makes it stronger than regular glass. Tempered glass is up to five times stronger than regular glass, making it an excellent choice for high-traffic areas.

Energy efficiency

Frosted glass can help to improve energy efficiency by reducing the amount of heat that enters a room through windows. The matte surface diffuses the sunlight, reducing glare and heat gain.

Safety

Frosted glass is a safer option than clear glass as it is less likely to shatter. If it does break, it breaks into small, less harmful pieces.

Privacy

Frosted glass provides privacy by obscuring the view while still allowing natural light to pass through. This makes it an excellent choice for bathroom windows, shower enclosures, and office partitions.

Aesthetic appeal

Frosted glass can add a decorative element to any space, making it an excellent choice for interior design. It can be used for decorative wall panels, cabinet doors, and furniture.

What're disadvantages of frosted glass?

While frosted glass has many advantages, it also has some disadvantages that should be considered before choosing it for a particular application. Here are some of the disadvantages of frosted glass:

Reduced visibility

Frosted glass reduces visibility by obscuring the view, which may not be suitable for certain applications where clear visibility is necessary.

Limited light transmission

While frosted glass allows natural light to pass through, it also reduces the amount of light that enters the space.

Limited customization

Frosted glass is produced by etching or sandblasting a clear sheet of glass, which limits the degree of customization.

Cost

Frosted glass can be more expensive than clear glass, which may not be suitable for applications where cost is a concern.

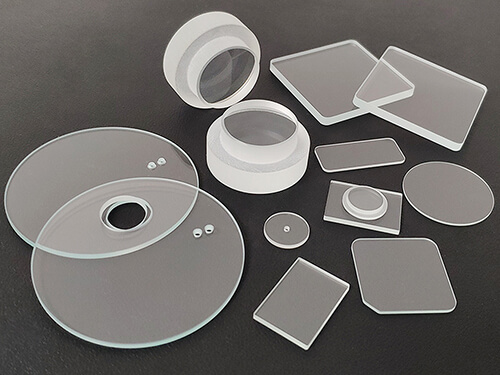

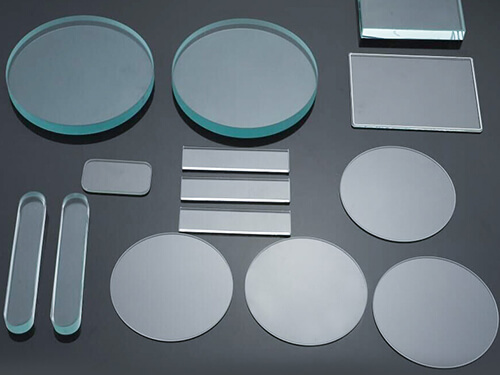

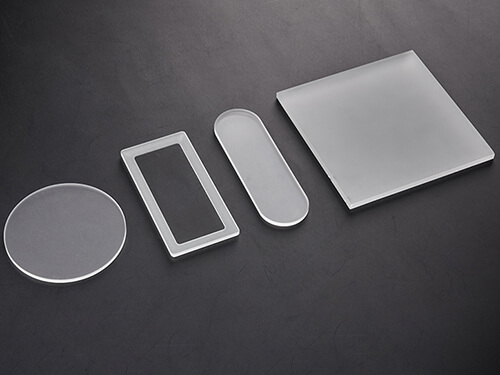

Custom Frosted Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

What's custom Frosted glass laser cutting service?

Laser cutting custom frosted glass service is a process of using a high-powered laser beam to cut and etch patterns, designs, or shapes into a piece of frosted glass.

Frosted glass is a type of glass that has been chemically treated or sandblasted to create a matte or opaque surface, making it ideal for privacy or decorative purposes.

With laser cutting, precise and intricate designs can be achieved on the frosted glass surface, allowing for a wide range of customization options.

The laser beam is directed by a computer-controlled system, which follows a digital design file to cut and etch the glass surface.

How to ensure the precision of the custom laser cutting frosted glass parts?

To ensure the precision of frosted glass sheets cut to size service, here are some key steps that can be taken:

Accurate measurements:

The first step in ensuring precision is to take accurate measurements of the glass sheets. This can be done using a high-quality measuring tool, such as a digital caliper or a laser measuring device. It's important to measure the glass sheets multiple times to ensure accuracy.

Quality control:

A reliable and experienced glass cutting service provider will have a strict quality control process in place to ensure the accuracy of the cuts. This includes regularly calibrating the cutting equipment and conducting quality checks on the finished products.

Use of advanced cutting technology:

Using advanced cutting technology, such as computer-controlled laser cutting machines, can help ensure precise and consistent cuts.

Skilled professionals:

The cutting process should be carried out by skilled professionals who have experience and training in glass cutting. They should be familiar with the specific characteristics of frosted glass and be able to make adjustments to the cutting process as needed.

Material selection:

The quality and consistency of the frosted glass sheets being used should also be considered. The sheets should be of high quality and consistent thickness to ensure that the final product is cut to the desired size and shape.

By following these steps, the precision of frosted glass sheets cut to size service can be ensured, resulting in high-quality finished products that meet the customer’s specifications.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom frosted Glass Parts Into Production Today

Want to save time and money on your frosted glass parts project? Contact us now. Our factory provides high-quality precision custom frosted glass products at very competitive prices and fast production times. We support free sample service.