CNC Laser Cutting Service

High-quality glass & sapphire glass CNC laser cutting service supplier at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass & sapphire glass CNC laser cutting service?

Glass & sapphire glass CNC laser cutting service refers to the process of using computer numerical control (CNC) technology and laser cutting technology to precisely cut and shape glass & sapphire glass materials.

CNC laser cutting involves the use of a high-powered laser beam to cut through the glass along a programmed path, guided by a computer-controlled system.

HY manufacturer specializes in laser-cutting glass parts and sapphire parts. Our factory produces premium laser-cut glass and sapphire components at factory-direct prices.

Contact us to get a free quote for your custom CNC laser-cutting glass & sapphire glass parts.

What are the properties of glass & Sapphire Glass CNC laser cutting?

Glass & sapphire glass CNC laser cutting exhibits several properties that make it a preferred method for cutting glass materials. Here are some key properties associated with glass CNC laser cutting:

Precision

CNC laser cutting provides exceptional precision and accuracy, allowing for intricate and detailed cuts on glass surfaces. The focused laser beam can achieve precise cuts with minimal heat-affected zones, resulting in clean edges and minimal distortion.

Versatility

Glass CNC laser cutting is versatile and can be used with various types of glass, including float glass, tempered glass, laminated glass, and specialty glass. It can accommodate different glass thicknesses and sizes, making it suitable for a wide range of applications.

Flexibility

CNC programming enables flexibility in design and cutting patterns. Changes to the design can be made easily in the CAD software, and the CNC machine can quickly adapt to the new instructions without requiring physical tool changes. This flexibility allows for customization and quick prototyping.

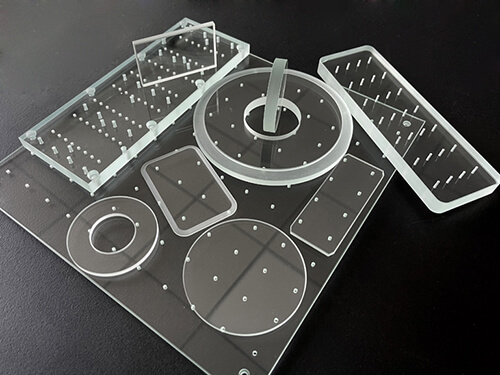

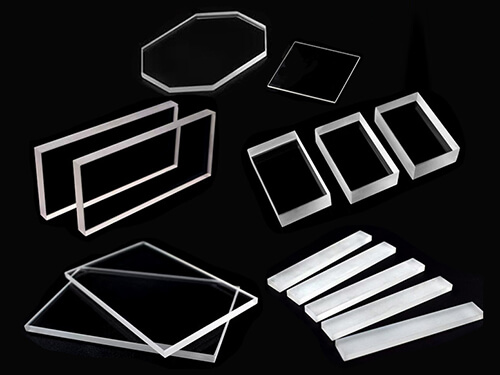

Complex Shapes and Intricate Designs

Glass CNC laser cutting can create complex shapes and intricate designs that may be challenging to achieve with traditional cutting methods. The precise control provided by CNC technology allows for the realization of intricate patterns, curves, angles, and internal cutouts.

Speed and Efficiency

CNC laser cutting is a fast and efficient process. Once the design is programmed, the CNC machine can execute the cutting process quickly and consistently, ensuring high productivity. Additionally, the automation of the process eliminates the need for manual intervention, reducing labor requirements and increasing overall efficiency.

Non-contact Process

CNC laser cutting is a non-contact cutting process, meaning the laser beam does not physically touch the glass surface. This eliminates the risk of damage or scratches caused by contact-based cutting methods.

It’s important to note that the properties of glass CNC laser cutting can vary depending on the specific laser cutting system, the type and thickness of the glass material, and other factors. It’s always recommended to consult with HY to understand the specific capabilities and limitations of their equipment and processes.

Types of glass & sapphire glass CNC laser cutting?

Glass CNC laser cutting can be classified into different types based on the specific laser technology used or the intended application. Here are a few common types of glass CNC laser cutting:

CO2 Laser Cutting

CO2 (carbon dioxide) lasers are widely used for glass CNC laser cutting. They emit a laser beam with a wavelength of around 10.6 micrometers, which is well-suited for cutting glass. CO2 lasers are capable of cutting through a range of glass thicknesses, from thin glass sheets to thicker materials.

Fiber Laser Cutting

Fiber lasers, typically used for metal cutting, can also be utilized for glass CNC laser cutting. Fiber lasers emit a laser beam with a wavelength around 1.0 to 1.1 micrometers, which is absorbed more efficiently by glass compared to CO2 lasers. Fiber lasers can achieve high cutting speeds and are often used for thin glass-cutting applications.

UV Laser Cutting

UV (ultraviolet) lasers are specifically designed for cutting transparent materials such as glass. UV lasers emit a laser beam with a wavelength in the ultraviolet spectrum, typically around 355 nanometers. This wavelength is absorbed well by glass, allowing for precise and clean cuts. UV laser cutting is commonly used for delicate glass-cutting applications, such as cutting display glass for electronic devices.

Pulsed Laser Cutting

Pulsed laser cutting involves using laser beams with pulsed outputs, where the laser power is delivered in short pulses rather than a continuous beam. Pulsed lasers can provide precise control over the energy delivered to the glass material, minimizing heat transfer and reducing the risk of thermal damage. This type of cutting is often used for fragile or thin glass materials.

3D Laser Cutting

3D laser cutting involves using CNC systems capable of moving the laser head in multiple axes, enabling the cutting of complex three-dimensional shapes. With 3D laser cutting, intricate and curved designs can be achieved on glass surfaces, allowing for greater design flexibility.

What are the benefits of glass & Sapphire glass CNC laser cutting?

Precision

CNC technology ensures accurate and consistent cutting according to the programmed design, allowing for intricate and complex shapes to be achieved.

Versatility

CNC laser cutting can be used with various types of glass, including tempered glass, laminated glass, and even fragile materials like thin glass sheets.

Efficiency

The process is automated and highly efficient, enabling fast and precise cutting with minimal material waste.

Flexibility

The digital nature of CNC programming allows for easy modifications and adjustments to the design without requiring physical tool changes.

Glass & Sapphire glass CNC laser cutting services are commonly utilized in industries such as architecture, interior design, automotive, electronics, and art, where precise and customized glass components or decorative pieces are required.

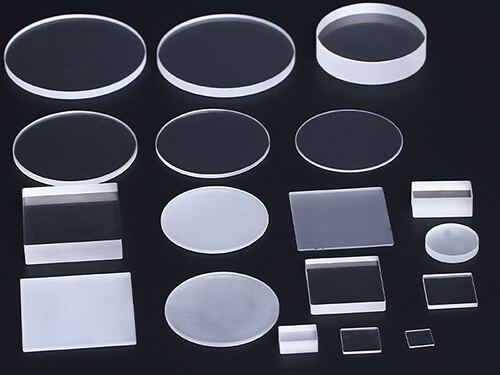

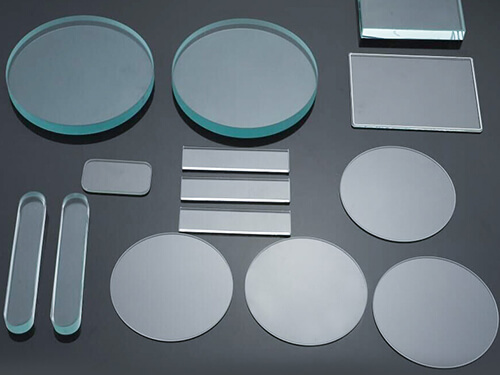

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass & Sapphire Glass Parts Into Production Today

Want to save time and money on your custom glass and sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom glass and sapphire glass parts at very competitive prices and fast production times. We support sample service.