Hot Bending service

Precision custom glass hot bending service factory at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is glass hot bending service?

Glass hot bending service refers to a process in which glass is heated to a high temperature and then shaped or molded into a desired form while it is pliable. This technique allows for the creation of curved, bent, or shaped glass pieces that can be used in various applications.

HY factory specializes in providing custom OEM hot bending services for glass parts parts. Our factory produces premium glass components at factory-direct prices.

Contact us to get a free quote for your custom glass parts.

What are the properties of glass hot bending?

Here are some of the properties associated with glass hot bending:

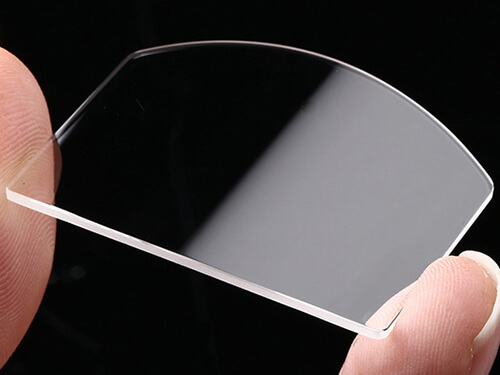

Curvature

The primary property of hot bent glass is its curved shape. The glass is shaped into various degrees of curvature, ranging from gentle curves to more pronounced bends. The curvature can be customized to meet specific design requirements and aesthetic preferences.

Strength

The properly hot-bent glass retain its strength and structural integrity. The heating and annealing process helps relieve internal stresses, ensuring the glass maintains its durability and safety properties.

Visual Distortion

Hot-bent glass may exhibit slight visual distortion, especially in larger and more pronounced bends. This distortion can manifest as mild waviness or optical irregularities due to the bending and cooling process. The level of distortion can vary depending on the degree of curvature and the specific glass composition.

Optical Quality

While hot bent glass may have slight visual distortions, it generally maintain acceptable optical quality. It allows light to pass through, albeit with potential variations in refraction and reflection. The optical properties of hot bent glass can be further enhanced by using high-quality glass and precise manufacturing techniques.

Versatility

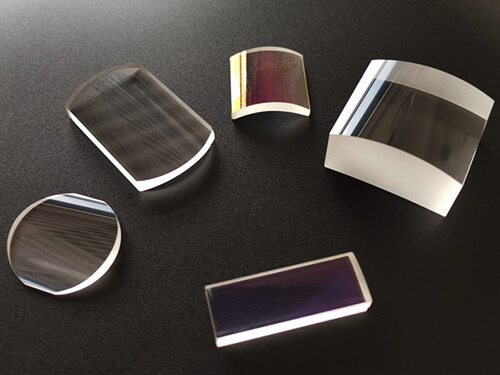

Glass hot bending allows for versatile design possibilities. It enables the creation of various forms and shapes, including cylindrical curves, S-curves, helical bends, or more intricate geometries.

Aesthetics

Hot bent glass offers unique aesthetic appeal. Its curved shape can add elegance, visual interest, and a sense of fluidity to architectural or design applications. The smooth curves and absence of sharp edges contribute to a sleek and modern appearance.

Types of glass hot bending?

Glass hot bending encompasses different techniques and methods to achieve various types of curved or bent glass. Here are some common types of glass hot bending:

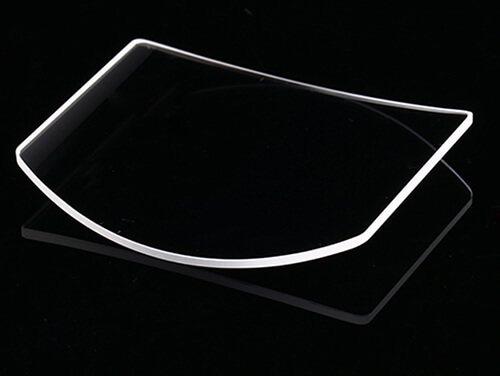

Single Curvature Bending

This technique involves bending the glass along a single axis, resulting in a curved glass surface in one direction. It is commonly used to create simple curved glass elements like cylindrical or cylindrical-like shapes.

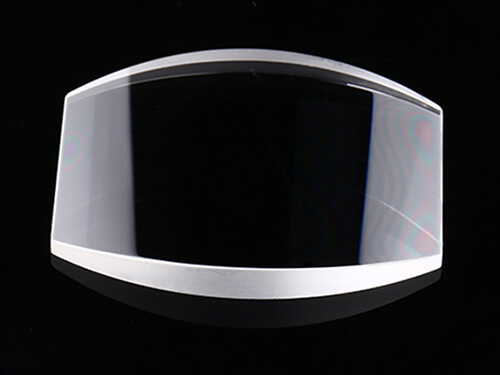

Double Curvature Bending

In this method, the glass is bent along two axes, producing a complex curved surface in two directions. Double curvature bending allows for the creation of more intricate and organic shapes, such as spherical or free-form curves.

Radius Bending

Radius bending involves bending the glass to form a specific radius or arc. The glass is heated and shaped to achieve a constant and consistent curvature throughout the glass surface. It is often used to create curved glass panels, curved glass windows, or glass balustrades with a consistent radius.

Press Bending

Press bending is a technique where the glass is heated and pressed between two molds or tools to achieve a specific curvature. This method is commonly used to produce consistent, uniform bends, such as in automotive windshields or large-scale architectural glasspanels.

Vacuum Forming

Vacuum forming utilizes a combination of heat and vacuum pressure to shape the glas. The heated glass is placed over a mold, and the vacuum is applied to force the glass to conform to the mold's shape. Vacuum forming allows for the creation of precise and intricate curves, making it suitable for producing complex glass components.

What are the benefits of glass hot bending?

Design Flexibility

Hot bending allows for the creation of custom curved or bent glass shapes that are not achievable with flat glass. It provides designers and architects with increased design freedom to create unique and visually striking elements. The ability to incorporate curves and bends opens up new possibilities for innovative and creative designs.

Structural Strength

Despite the bending process, hot bent glass can maintain its structural integrity and strength. Proper annealing ensures that the glass retains its durability and safety properties.

Space Optimization

Curved glass elements can optimize space utilization by fitting into challenging or unconventional areas. They can be used to create curved partitions, curved countertops, or curved glass displays, making efficient use of available space while adding functionality and style.

Acoustic Benefits

Curved glass has the potential to improve acoustic performance by reducing sound reflections and enhancing sound dispersion. This can be advantageous in spaces where noise control is important, such as concert halls, auditoriums, or office environments.

Custom Glass & Sapphire Glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Sapphire Glass Lens

- Sapphire Window

- Quartz Glass Sight Glass

- Heat-insulating Glass

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Glass Parts Into Production Today

Want to save time and money on your custom glass parts project? Contact us now. Our factory provides high-quality precision custom glass parts at very competitive prices and fast production times. We support sample service.