Reducing the cost of custom-shaped frosted glass requires considering several factors that affect the overall cost of production. Here are a few suggestions:

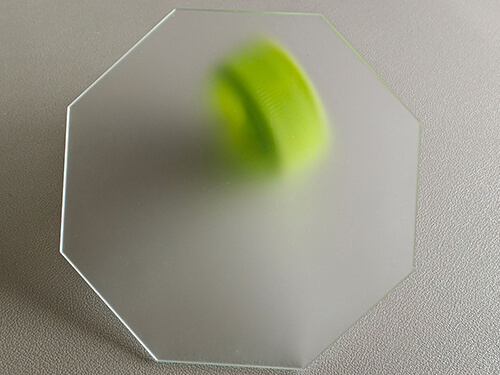

Opt for simpler shapes

Complex shapes, such as curves or irregular shapes, require more time to produce, which can increase the cost. Choosing simpler shapes, such as rectangles or squares, can help to reduce the cost.

Use standard glass thickness

Custom thickness for frosted glass can be more expensive than standard thickness. Consider using standard thickness for your frosted glass to reduce the cost.

Consider alternative frosting methods

Different frosting methods can have varying costs. Consider alternative frosting methods like frosting films or acid etching to achieve the desired effect at a lower cost.

Order in bulk

If you need multiple pieces of custom-shaped frosted glass, ordering in bulk can help to reduce the cost per unit. Be sure to inquire about bulk pricing and discounts when obtaining quotes.

Shop around

Compare prices from different vendors and manufacturers to find the best deal. Be sure to factor in shipping and handling costs when comparing prices.