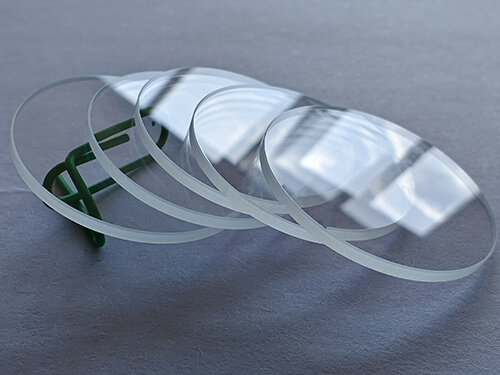

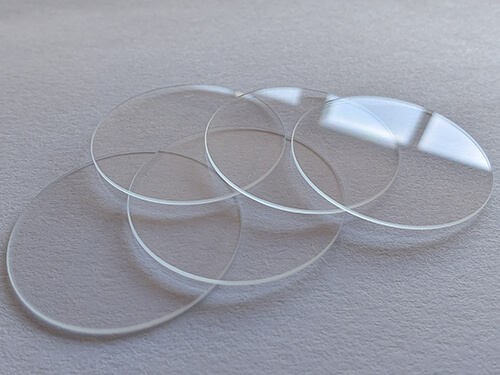

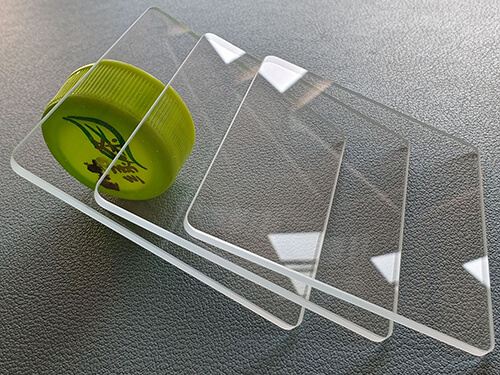

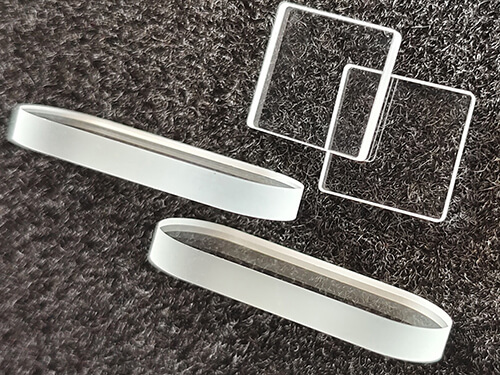

Custom Low Iron Glass (Soda-Lime) Service

High-quality custom Low Iron Glass (Soda-Lime) parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is low iron glass?

Low iron glass is a type of high-quality, clear glass that is made with reduced iron content. It is also known as extra clear glass, ultra-clear glass, or starphire glass. The iron content in regular clear glass can give it a greenish tint, but low iron glass is designed to eliminate this tint, resulting in a crystal-clear appearance.

Low iron glass is made by using raw materials with a low iron content and refining the glass-making process to remove impurities. This results in a glass with a higher light transmission and color rendering index (CRI) than regular clear glass. Low iron glass typically has a light transmission of around 91-93%, compared to around 83-84% for regular clear glass.

Due to its high transparency, low iron glass is commonly used in applications where clarity and aesthetics are important. It is often used in architectural and interior design projects, such as glass doors, partitions, and shower enclosures. It is also used in the production of solar panels, aquariums, and display cases, where color accuracy and high light transmission are important.

Low iron glass can be further enhanced with coatings, such as low-emissivity coatings, to improve its energy efficiency and reduce heat transfer through windows. This makes it an ideal choice for use in energy-efficient buildings and homes.

What are the properties of low iron glass?

High light transmission

Low iron glass has a higher light transmission than regular clear glass, with a typical range of 91-93%, compared to around 83-84% for regular clear glass.

Color neutrality

Low iron glass has a crystal-clear appearance with minimal color distortion. It eliminates the greenish tint that is often present in regular clear glass, making it ideal for applications where color accuracy and clarity are important.

High clarity

Low iron glass has a high degree of optical clarity, allowing for unobstructed views and maximum light transmission. This makes it ideal for use in applications such as display cases, aquariums, and solar panels.

Durability

Low iron glass is typically made with high-quality materials and manufacturing processes, making it strong and durable. It can be tempered or laminated for added strength and safety.

Energy efficiency

Low iron glass can be coated with low-emissivity (low-E) coatings to improve its energy efficiency and reduce heat transfer through windows. This makes it an ideal choice for use in energy-efficient buildings and homes.

Chemical resistance

Low iron glass is resistant to chemical corrosion and is not easily etched or stained. It is also easy to clean and maintain.

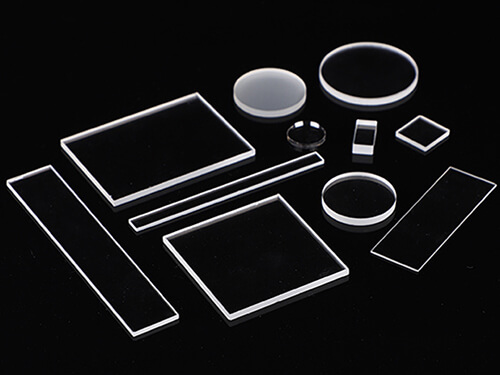

Types of low iron glass?

There are several types of low iron glass, each with unique properties and characteristics. Some of the most common types of low iron glass include:

Clear low iron glass

This is the most common type of low iron glass and has a crystal-clear appearance with minimal color distortion. It is ideal for applications where maximum light transmission and color accuracy are important.

Acid-etched low iron glass

Acid-etched low iron glass also name frosted glass has a frosted appearance and is used for decorative or privacy applications. It can be used for shower enclosures, partitions, and interior design features.

Coated low iron glass

Coated low iron glass can be coated with low-emissivity (low-E) coatings to improve its energy efficiency and reduce heat transfer through windows. It can also be coated with other coatings, such as anti-reflective or self-cleaning coatings, for specific applications.

Insulated low iron glass

Insulated low iron glass consists of two or more panes of low iron glass with a sealed air or gas space between them. It provides improved energy efficiency and sound insulation and is commonly used for windows and doors in commercial and residential buildings.

Tinted low iron glass

Tinted low iron glass has a slight color tint that can be used for aesthetic or functional purposes. For example, bronze or gray tinted low iron glass can be used to reduce glare and heat from the sun.

Laminated low iron glass

Laminated low iron glass consists of two or more sheets of glass with a clear or tinted interlayer between them. It provides added strength and safety and is commonly used for exterior applications, such as glass facades and balconies.

Applications of Low iron glass cutting service?

Custom low-iron glass can be used in a wide range of applications where clarity, color accuracy, and durability are important. Some common applications of custom low iron glass plate, panels, sight windows, and lens cutting services include:

Optical lenses

Low iron glass can be used for optical lenses in cameras, telescopes, and other precision instruments. Its high clarity and low color distortion make it ideal for lenses that require accurate light transmission.

Medical equipment

Low iron glass can be used for medical equipment, such as microscopes and laboratory equipment. Its high clarity and color neutrality make it ideal for applications where accurate color representation is important.

Solar panels

Low iron glass can be used as the cover glass for solar panels. Its high light transmission allows for maximum energy absorption, improving the efficiency of the solar panels.

Architectural glass

Low iron glass can be used for exterior and interior architectural applications, such as windows, doors, facades, and glass walls. It provides maximum light transmission and color accuracy, making it ideal for modern and minimalist designs.

Display cases

Low-iron glass can be used for display cases in museums, art galleries, and retail stores. It is high clarity and color accuracy allow for unobstructed views of the items on display.

What advantages of custom Low iron glass parts?

Low iron glass offers several advantages over standard clear glass, including:

Higher light transmission

Low iron glass allows more light to pass through than standard clear glass, making it ideal for applications where maximum light transmission is desired, such as windows and solar panels.

Better color accuracy

Low iron glass has a higher degree of color neutrality than standard clear glass, meaning it transmits colors more accurately and without distortion. This makes it ideal for applications where color accuracy is important, such as display cases and optical lenses.

Higher clarity

Low iron glass has a higher level of clarity than standard clear glass, making it ideal for applications where a crystal-clear appearance is desired, such as glass facades and aquariums.

Increased design flexibility

Because of its high clarity and color accuracy, low iron glass provides designers with more flexibility and creative options than standard clear glass.

Improved energy efficiency

Low iron glass can be coated with low-emissivity (low-E) coatings to improve its energy efficiency and reduce heat transfer through windows.

Increased durability

Low iron glass is generally more durable than standard clear glass and less likely to break or chip.

What're disadvantages of Low iron glass?

Low iron glass, also known as ultra-clear glass or extra-clear glass, is a type of glass that has reduced iron content to minimize the greenish tint that is commonly found in regular clear glass. Although low iron glass offers many advantages over regular clear glass, it also has some disadvantages, including:

Higher Cost

Low iron glass is generally more expensive than regular clear glass due to the extra manufacturing processes required to remove the iron content.

Reduced Durability

Low iron glass is more fragile than regular clear glass and is more prone to breaking or cracking. This can make it unsuitable for certain applications where durability is important, such as in safety glass or structural glazing.

More Visible Streaking

Low iron glass is more prone to showing visible streaking and smudging compared to regular clear glass, which can be particularly noticeable when used in large sheets or panels.

Higher Reflection

Low iron glass has a higher reflection rate than regular clear glass, which can create unwanted reflections and glare in some applications.

Not UV Resistant

Low iron glass does not have UV-resistant properties, which means it does not protect against UV radiation. This can be a disadvantage in certain applications, such as in skylights or greenhouse glazing where UV protection is important.

Get Your CustomLow iron glass Parts Into Production Today

Want to save time and money on your Low iron glass parts project? Contact us now. Our factory provides high-quality precision custom Low iron glass products at very competitive prices and fast production times. We support free sample service.