Optical Sapphire Dome for Aerospace refers to the use of synthetic sapphire in the fabrication of optical domes utilized in aerospace applications, particularly for military and advanced civilian technologies.

Recognized for its exceptional optical clarity, durability, and high-temperature resistance, sapphire serves as a critical material in various aerospace systems, including navigation, surveillance, and environmental monitoring.

The significance of optical sapphire domes lies in their ability to withstand extreme environmental conditions while maintaining superior optical performance, making them indispensable in high-stakes applications like thermal imaging and advanced avionics.

The development of synthetic sapphire can be traced back to the late 19th century, with advancements made by scientists such as Auguste Verneuil who pioneered the flame-fusion method for producing synthetic gemstones.

Over the years, various production techniques, including the Kyropoulos and Edge-Defined Film-Fed Growth methods, have improved the quality and cost-effectiveness of synthetic sapphire, leading to its widespread adoption across multiple industries, especially aerospace and defense.

The growing demand for high-performance materials in these sectors highlights the notable trajectory of sapphire technology and its integration into modern systems.

Despite its advantages, the optical sapphire dome market faces several challenges, including high production costs, competition from alternative materials like tempered glass, and supply chain disruptions.

These factors have led to ongoing debates about the viability of sapphire compared to emerging materials that may offer similar performance at lower costs.

Moreover, the complexity of manufacturing processes continues to pose obstacles to the broader adoption of sapphire in various applications. Looking ahead, the future of optical sapphire domes in aerospace appears promising, driven by increasing demand for advanced materials and sustainability initiatives within the industry.

Innovations in production techniques, coupled with a growing emphasis on eco-friendly manufacturing processes, are likely to enhance the accessibility and application of synthetic sapphire, positioning it as a vital component in the next generation of aerospace technologies.

History

Early Developments in Synthetic Sapphire

The journey of synthetic sapphire began in the late 19th century, primarily influenced by the pioneering work of Auguste Verneuil. In 1880, Verneuil encountered synthetic rubies sold by a Genevan merchant, which were initially dismissed as artificial.

However, these “Geneva rubies” are now recognized as the first examples of flame-fusion-produced rubies, predating Verneuil’s later advancements by two decades.

Inspired by these findings, Verneuil sought to develop a method for recrystallizing finely ground aluminum oxide into large gemstones.

His innovations were catalyzed by the advent of the oxyhydrogen torch and the growing demand for synthetic alternatives.

Verneuil’s design for the Verneuil furnace, introduced in 1902 and detailed in publications by 1904, involved melting finely ground alumina mixed with chromium oxide at temperatures exceeding 2,000 °C (3,630 °F).

The resulting process facilitated the creation of sizable crystals, laying the foundation for synthetic sapphire production.

Advancements and Market Expansion

As technology progressed, synthetic sapphire gained traction across various industries.

The introduction of refined production techniques, such as the Kyropoulos (KY) and Edge-Defined Film-Fed Growth (EFG) methods, significantly improved the cost-effectiveness of manufacturing high-quality synthetic sapphire.

These advancements broadened the material’s accessibility and applications, particularly in aerospace and defense sectors, where high-performance materials are in high demand.

Despite the challenges posed by production costs, the industry adapted during the COVID-19 pandemic, focusing on enhancing production efficiencies and investing in research and development.

Additionally, the rising emphasis on sustainability led to explorations of eco-friendly production methods and the use of sapphire in renewable energy technologies.

Current Trends and Future Prospects

Today, synthetic sapphire is integral to numerous applications, including optical coatings and aerospace components.

The ongoing evolution of sapphire production methods, along with the growing global defense budgets and the push for advanced materials, indicate a promising future for synthetic sapphire in aerospace and beyond.

The historical trajectory of synthetic sapphire, rooted in Verneuil’s initial experiments, reflects a dynamic interplay of innovation and market demand that continues to shape its role in modern technology.

Materials and Properties

Overview of Optical Materials

The choice of materials for optical applications in aerospace is crucial due to the demanding operational environments. Sapphire, spinel, and ALON are some of the key materials that meet the requirements for both visible (VIS) and infrared (IR) spectral regions.

These materials exhibit excellent optical performance, high mechanical strength, and thermal survivability, making them suitable for high-speed and harsh environment applications.

Sapphire

Sapphire is renowned for its durability and high-temperature capability.

It is an effective optical material for IR applications, exhibiting low emittance characteristics that are advantageous for reducing thermal signatures in systems such as domes.

The temperature dependence of its infrared refractive index plays a vital role in the performance of sapphire as an optical dome material.

Mechanical Properties

Recent advancements in polishing technology have significantly improved the mechanical properties of sapphire, allowing for minimal subsurface damage and extremely low surface roughness.

These improvements not only enhance the mechanical strength of sapphire components but also reduce surface drag when exposed to various environmental conditions.

Beryllium Oxide (BeO)

High-density, polycrystalline beryllium oxide (BeO) has been identified as a material with low emittance in the primary atmospheric window of 8 – 13 micrometers, owing to its strong reststrahlen band.

This characteristic makes BeO suitable for applications where thermal signature reduction is critical.

Bulk reflectance spectra have been reported for various grades of ceramic BeO, illustrating its effective performance in IR applications.

Thin Films and Coatings

The application of thin coatings for mechanical protection and optical enhancement is increasingly common in aerospace.

Various coatings, such as diamond and amorphous carbon, provide significant resistance against rain and sand erosion, enhancing the durability of optical windows and domes.

Innovative developments in coating technologies have resulted in ultra-durable coatings based on phosphide materials that improve the environmental durability of IR transmissive surfaces, specifically against high-velocity impacts.

Transparent Silicon Carbide (SiC)

Transparent beta-SiC is another promising candidate for aerospace optical applications.

It exhibits high optical transmission in the wavelength range of 0.5 to 6 micrometers and possesses remarkable hardness, electrical resistivity, and thermal conductivity.

These properties make it particularly well-suited for use in severe environments encountered in high-speed missiles and space systems.

Reliability and Testing

To ensure the reliability of optical materials in aerospace applications, extensive testing is conducted.

For instance, dual-pane glass concepts have been developed that exhibit a safe life exceeding 10,000 hours and are designed to be failsafe in the event of catastrophic failures.

Such testing validates crack growth parameters and survival probability under various simulated conditions, ensuring that these materials can withstand the rigors of aerospace environments.

Design and Engineering Of Optical Sapphire Dome

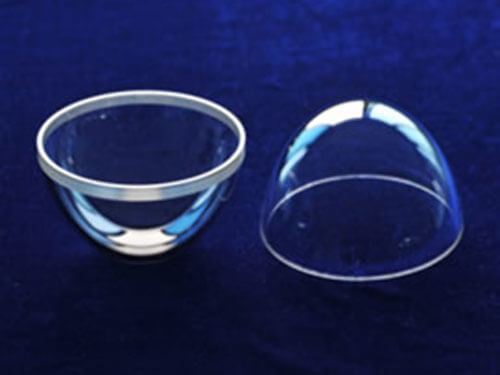

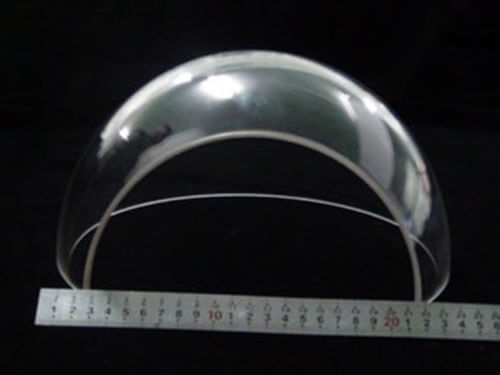

Overview of Optical Domes

Optical domes are crucial components in aerospace applications, offering enhanced fields of view compared to flat ports.

They are extensively used in systems such as underwater cameras, aircraft navigation systems, and surveillance instruments.

Their design must ensure both protection of the optical systems and optimal performance under varied conditions, requiring a careful balance between material selection and structural integrity.

Key Design Considerations Of Optical Sapphire Dome

Material Selection

Choosing appropriate materials is fundamental for achieving optimal optical and mechanical performance.

The materials used must possess the requisite optical properties, such as refractive index and dispersion, as well as mechanical attributes like strength and durability.

Synthetic sapphire, for instance, is often favored for its excellent optical clarity and resistance to environmental stressors, making it suitable for high-performance applications.

Curvature and Optical Characteristics

The curvature of the dome significantly influences its optical traits, including field of view and image sharpness.

Designers must carefully consider the dome’s shape to minimize optical distortion caused by refraction and reflection.

Achieving the right balance among these factors is critical and often involves tailored design strategies to meet specific application needs.

Coatings and Surface Treatment

Applying anti-reflective coatings can further enhance the optical performance of domes by reducing reflection losses and improving light transmission.

The surface treatment processes, such as plasma polishing or diamond coatings, can also help in achieving smoother surfaces, which are vital for minimizing scattering and maintaining image clarity.

Engineering Challenges and Innovations

The engineering of optical domes involves addressing various challenges, including the effects of environmental conditions and potential structural failures.

A dual-pane glass concept has been developed to withstand extreme conditions while ensuring safety. This design, tested for crack growth parameters and survival probability, aims to provide a failsafe solution for high-stress environments common in aerospace applications.

Additionally, the integration of advanced materials like sapphire hyper-hemispherical domes has opened new avenues for enhancing optical systems’ performance and capabilities, particularly in infrared countermeasure systems.

Applications Of Optical Sapphire Dome

Optical sapphire domes are crucial components in various aerospace applications due to their superior optical properties, durability, and resistance to environmental factors.

These domes serve as protective windows for sensors and equipment, enabling the transmission of infrared and visible light while safeguarding internal components from contaminants and mechanical damage.

Surveillance and Reconnaissance

In military and defense operations, optical sapphire domes are utilized in surveillance and reconnaissance systems.

Their excellent transmittance in the infrared (IR) spectrum, particularly in the long-wave infrared (LWIR) range (8-12 µm), makes them ideal for thermal imaging applications, allowing for effective monitoring in diverse environmental conditions.

This capability is enhanced by the use of anti-reflective (AR) coatings, which minimize reflection and improve transmission efficiency, critical for high-performance thermal cameras.

Aerospace Navigation Systems

Optical sapphire domes also play a vital role in aerospace navigation systems.

They are employed in sensors that require high optical clarity and mechanical strength to withstand the rigors of flight.

The robustness of sapphire material ensures reliable performance in harsh environments, making it suitable for applications such as heads-up displays (HUDs) and advanced avionics systems, where clarity and precision are paramount.

Environmental Monitoring

In the realm of environmental science, optical sapphire domes are integral to gas detection and monitoring systems.

Utilizing infrared spectroscopy, these domes allow for high transmission at specific absorption wavelengths of gases, which is essential for accurate spectral readings in various industries, including petrochemical processing and healthcare.

This application underscores the versatility of sapphire as a material that can enhance detection capabilities while maintaining resilience against environmental challenges.

Emerging Technologies

Innovations in the field of adaptive IR windows represent a promising frontier for optical sapphire domes.

These advanced systems can dynamically adjust their optical properties based on environmental conditions, enabling their integration into smart sensing systems, including those found in autonomous vehicles and next-generation defense technologies.

As the demand for sophisticated optical solutions continues to grow, the applications of sapphire domes are expected to expand, driving further advancements in aerospace technology.

Advantages

Optical sapphire domes offer a multitude of advantages, particularly in demanding applications such as aerospace.

One of the most significant benefits is their exceptional mechanical properties.

Sapphire is renowned for its high hardness and strength, allowing it to withstand challenging industrial environments, including military and aerospace contexts where equipment must endure extreme conditions.

This resilience ensures that sapphire domes remain functional even when exposed to harsh environmental factors such as high-speed impacts from rain, sand, and debris during flight.

Optical Performance

Sapphire windows exhibit excellent optical transparency across a broad wavelength range, including ultraviolet (UV), visible, and infrared (IR) spectra.

This high optical clarity makes sapphire ideal for multispectral devices, such as thermal cameras and infrared imaging systems.

Its capability to transmit light across these diverse ranges meets the stringent demands of advanced optical applications, contributing to improved performance in both military and civilian technologies.

Chemical Stability and Durability

Another advantage of sapphire is its chemical stability, which ensures longevity and reliability in various applications.

Unlike traditional optical materials like glass and fused silica, which are more prone to scratching and shattering, sapphire offers enhanced durability under extreme conditions.

This characteristic is crucial for aerospace applications, where window materials must be able to resist abrasion and maintain their optical properties despite exposure to harsh elements.

High-Temperature Resistance

Sapphire’s ability to withstand high temperatures further solidifies its position as a preferred material for aerospace applications.

The combination of mechanical strength and high-temperature survivability makes sapphire optics particularly suitable for equipment operating in environments that experience rapid temperature fluctuations and high thermal loads during flight.

Environmental Resilience

The design of sapphire domes accounts for environmental resilience, ensuring they can function effectively in extreme conditions.

This includes pressure resistance and temperature stability, both vital for aerospace applications where operational environments can vary widely.

Moreover, the use of anti-reflective coatings on sapphire domes can enhance light transmission, contributing to overall optical performance while protecting the dome from environmental damage.

Challenges

The optical sapphire dome market for aerospace applications faces several significant challenges that impact its growth and adoption.

Production Costs

One of the primary hurdles is the high cost associated with sapphire production.

The processes required to manufacture high-quality synthetic sapphire, such as the Kyropoulos method, are labor-intensive and expensive, leading to higher final product prices that limit accessibility for various applications.

Compared to alternative materials like tempered glass or Gorilla Glass, which offer adequate durability at a more cost-effective price, sapphire struggles to justify its higher costs unless it can demonstrate unique advantages in specific applications.

Competition from Alternative Materials

Intense competition from alternative materials also poses a challenge for sapphire.

In sectors like consumer electronics, alternatives such as Gorilla Glass have become increasingly popular due to their balance of strength, scratch resistance, and lower production costs.

The innovation in glass and ceramics continues to evolve, with ongoing improvements in performance characteristics, thus increasing the pressure on the sapphire industry to adapt and provide compelling reasons for its continued use.

Supply Chain Disruptions

Furthermore, supply chain disruptions have had a notable impact on the sapphire industry.

The global nature of sapphire production means that restrictions in one region can create ripple effects worldwide, resulting in delays in raw material procurement and transportation bottlenecks.

The challenges in workforce availability have also hindered timely delivery, prompting companies to explore diversification in supply chains and local sourcing options to mitigate these effects.

Manufacturing Complexity

Another significant challenge lies in the complexity of manufacturing processes.

The sapphire industry must overcome the cost and complexity of production, particularly as the shift toward synthetic sapphire continues. While advancements in production methods like the Edge-Defined Film-Fed Growth (EFG) technique have improved cost-effectiveness, the high production costs still limit the material’s adoption in various sectors, particularly where budget constraints are a concern.

Reliability and Performance Issues

Finally, issues related to the reliability and performance of sapphire domes in aerospace applications must be addressed. These components are often subject to extreme conditions, including high-stress environments that can lead to failure if not properly managed.

Understanding the mechanical properties and potential failure modes of sapphire is crucial for ensuring the safety and effectiveness of optical domes in aviation contexts.

Future Developments

The future of the optical sapphire dome market in aerospace is promising, driven by increasing demand for high-performance materials across various sectors, including electronics, defense, and medical devices.

Synthetic sapphire’s superior properties—such as hardness, optical clarity, and thermal resistance—position it as an ideal material for applications like aircraft cockpit displays and advanced sensors.

Market Growth and Opportunities

Analysts project that the synthetic sapphire market will grow significantly, with estimates suggesting it could reach a market size of $8.23 billion by 2028, representing a compound annual growth rate (CAGR) of 7.7%.

This growth is fueled by the expanding use of sapphire in optoelectronics and automotive applications, particularly as a material for sensors and display covers.

Furthermore, stricter environmental regulations are expected to drive demand for durable and sustainable materials, enhancing the appeal of synthetic sapphire in aerospace applications.

Sustainability Initiatives

A notable focus for future development is the sustainability of synthetic sapphire production.

While traditional manufacturing processes consume significant energy, ongoing research aims to reduce the environmental footprint of sapphire production.

Companies prioritizing eco-friendly methods stand to gain a competitive advantage as the market shifts toward sustainable practices.

Technological Innovations

Innovation in synthesis techniques remains crucial for the market’s evolution.

Advances in methods such as the Czochralski and Kyropoulos processes are making synthetic sapphire more affordable and accessible, which could further facilitate its adoption in aerospace applications.

Additionally, the integration of artificial intelligence (AI) and other emerging technologies within the aerospace sector will enhance manufacturing efficiencies and improve product performance, allowing for more sophisticated applications of synthetic sapphire.

Expansion in Aerospace and Defense

The aerospace and defense industries present lucrative opportunities for synthetic sapphire, driven by increasing global defense budgets and a focus on developing advanced aerospace technologies.

As these sectors continue to grow, the demand for high-performance materials is expected to rise, making synthetic sapphire an attractive investment area for companies looking to capitalize on this trend.