Custom Quartz glass Service

High-quality custom Quartz glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a sample service.

What is Quartz glass?

Quartz glass, also known as fused silica, is a type of glass made from pure crystalline silica. It is produced by melting high-purity silica at extremely high temperatures, typically over 1900 degrees Celsius, and then cooling it down rapidly to form a solid glass.

Quartz glass is a high-purity material with a number of unique properties that make it useful in a wide range of applications.

It has high optical clarity, excellent thermal shock resistance, high chemical resistance, and is mechanically strong.

It is often used in high-temperature applications such as furnace tubes, as well as in optics and photonics applications such as lenses, mirrors, and prisms.

Quartz glass is also used in the semiconductor industry for its high purity and ability to withstand high temperatures and corrosive environments.

Because of its unique properties, quartz glass is often a preferred material for applications where other materials such as traditional glasses, metals, or ceramics may not meet the necessary requirements.

What are the properties of Quartz glass?

Quartz glass, also known as fused silica, is a high-purity glass made from pure crystalline silica. It is an excellent material for a variety of applications due to its unique properties, including:

Chemical Properties

Inert to most chemicals, including acids and bases, which makes it an ideal material for use in chemical and pharmaceutical industries. Resistant to chemical attack by molten metals and glasses, which makes it suitable for use in high-temperature applications such as furnace tubes.

Thermal Properties

High thermal shock resistance due to its low coefficient of thermal expansion, which makes it suitable for use in high-temperature applications where sudden temperature changes occur. High thermal conductivity, which makes it an excellent material for use in heat exchangers and other thermal applications. The high melting point of approximately 1713°C, which makes it suitable for use in high-temperature applications.

Optical Properties

High optical clarity and transparency in the UV, visible, and IR regions of the electromagnetic spectrum, which makes it ideal for use in optics and photonics applications. Low birefringence, which makes it suitable for use in polarization-sensitive applications such as waveplates and polarizers.

Mechanical Properties

High mechanical strength and hardness, which makes it resistant to scratching and damage during handling and use. Low coefficient of thermal expansion, which reduces the risk of thermal stress and fracture. Low coefficient of friction, which makes it suitable for use in bearings and other sliding components.

Electrical Properties

Excellent electrical insulation properties, which makes it ideal for use in high-voltage applications such as insulators and electrical feedthroughs. High dielectric strength, which makes it suitable for use in high-power electronics applications.

Physical Properties

High density of approximately 2.2 g/cm³, which makes it heavier than most other glasses. High refractive index of approximately 1.46, which makes it an excellent material for use in optics and photonics applications. Low thermal expansion coefficient of approximately 0.5 x 10^-6 /°C, which makes it suitable for use in high-temperature applications.

Types of Quartz glass?

There are several types of quartz glass, each with its own specific properties and applications. Some of the common types of quartz glass include:

Fused silica

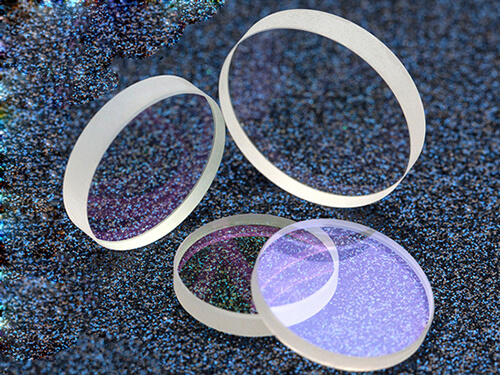

This is the purest form of quartz glass, made from high-purity crystalline silica that has been melted and rapidly cooled to form a solid glass. Fused silica has excellent optical clarity, high thermal shock resistance, and is often used in optics and photonics applications.

High-purity quartz glass

This type of quartz glass is made from high-purity quartz sand and has a lower impurity content than other types of quartz glass. It is often used in semiconductor manufacturing and other high-tech applications where a high level of purity is required.

Opaque quartz glass

This type of quartz glass contains microscopic air pockets that scatter light, giving it an opaque appearance. Opaque quartz glass is often used in diffusion and reflection applications in optics and photonics.

UV-transmitting quartz glass

This type of quartz glass has a high transmission of ultraviolet light and is often used in applications such as germicidal lamps and UV curing.

Infrared-transmitting quartz glass

This type of quartz glass has a high transmission of infrared light and is often used in high-temperature applications such as furnace tubes.

Synthetic quartz glass

This type of quartz glass is made from a synthetic material rather than natural quartz. It has similar properties to natural quartz glass but is often more uniform in composition and has better optical properties.

Applications of Quartz glass cutting service?

Quartz glass plate cutting services can provide custom-cut quartz glass plates to meet specific requirements for a wide range of applications. Some of the common applications of quartz glass plates include:

Optics and photonics

Quartz glass plates are often used in the manufacture of lenses, prisms, mirrors, and other optical components due to their high optical clarity and transmission properties.

Semiconductors

Quartz glass plates are used as components in semiconductor manufacturing equipment due to their high purity and ability to withstand high temperatures and corrosive environments.

Lighting

Quartz glass plates are used in the manufacture of high-intensity discharge lamps, halogen lamps, and other lighting applications due to their high thermal shock resistance and UV-transmitting properties.

Chemical and pharmaceutical industries

Quartz glass plates are often used in chemical reactors, distillation columns, and other equipment in the chemical and pharmaceutical industries due to their excellent chemical resistance.

Medical and biotechnology

Quartz glass plates are used in the manufacture of laboratory equipment and medical devices due to their high purity and biocompatibility.

Aerospace and defense

Quartz glass plates are used in a variety of applications in the aerospace and defense industries due to their high strength and durability.

What advantages of custom Quartz glass parts?

Quartz glass has unique properties that make it a preferred material for a wide range of applications. Its high purity, excellent optical properties, and ability to withstand high temperatures and harsh environments make it an ideal choice for use in industries such as semiconductor manufacturing, optics and photonics, and chemical and pharmaceutical manufacturing. Some of the key advantages of quartz glass include:

High purity

Quartz glass is made from high-purity silica and has a low impurity content, making it ideal for applications where purity is critical, such as in the semiconductor industry.

High thermal shock resistance

Quartz glass has a low coefficient of thermal expansion, which means it can withstand rapid changes in temperature without cracking or breaking.

Excellent optical properties

Quartz glass has a high optical clarity and can transmit ultraviolet, visible, and infrared light, making it ideal for use in optics and photonics applications.

Chemical resistance

Quartz glass is highly resistant to acids, bases, and other chemicals, making it ideal for use in chemical and pharmaceutical applications.

Mechanical strength

Quartz glass has a high strength-to-weight ratio and is resistant to scratches and abrasion, making it ideal for use in harsh environments.

Biocompatibility

Quartz glass is biocompatible, which makes it ideal for use in medical and biotechnology applications.

High-temperature resistance

Quartz glass can withstand temperatures up to 1200°C without softening or melting, making it ideal for use in high-temperature applications such as furnace tubes.

What're disadvantages of Quartz glass?

Quartz glass has many advantages, there are also some disadvantages to consider when using this material for certain applications. Here are some of the potential disadvantages of quartz glass:

Cost

Quartz glass can be more expensive than other types of glass due to the high purity of the raw materials and the complex manufacturing process.

Brittleness

While quartz glass is strong and durable, it is also brittle and can crack or break if subjected to mechanical stress or impact.

Difficult to machined

Quartz glass is a hard and abrasive material, which can make it difficult and time-consuming to machine into complex shapes.

Limited design options

Due to the challenges of machining quartz glass, there may be limitations on the design options available for certain applications.

Low thermal conductivity

While quartz glass has excellent thermal shock resistance, it has low thermal conductivity, which can make it unsuitable for some high-temperature applications.

Limited size options

Due to the challenges of manufacturing large pieces of quartz glass, there may be limitations on the size options available for certain applications.

The disadvantages of quartz glass may limit its use in certain applications, particularly those where cost or design limitations are a concern. However, for applications where purity, high-temperature resistance, and chemical resistance are critical, quartz glass remains a preferred material.

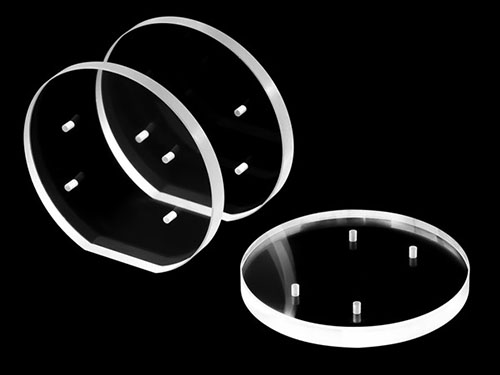

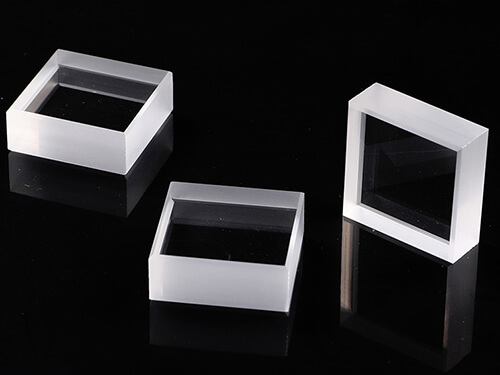

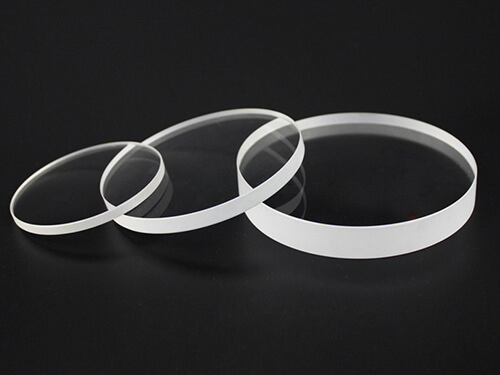

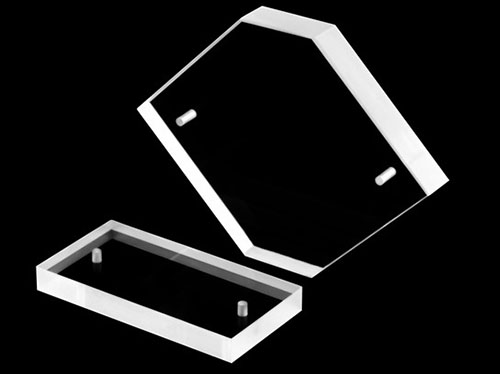

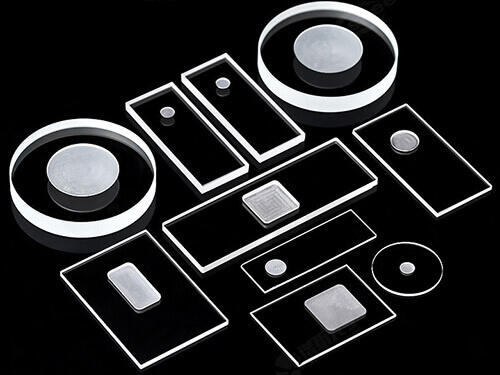

Custom Quartz glass Parts We Can Manufacture

- Frosted Glass Lens

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

What's custom Quartz glass laser cutting service?

Laser cutting custom quartz glass service is a process of using a high-powered laser beam to cut through quartz glass with high precision and accuracy.

The laser beam is directed onto the surface of the quartz glass, which is then melted and vaporized, creating a clean and precise cut.

This process is often used to create complex shapes and intricate designs that would be difficult or impossible to achieve using traditional cutting methods.

The laser cutting process for quartz glass is a non-contact process, meaning that the laser beam does not come into physical contact with the material.

This reduces the risk of contamination and damage to the quartz glass, making it an ideal choice for applications where high purity is critical, such as in the semiconductor industry.

Laser cutting custom quartz glass service can be used to create a wide range of shapes and sizes, including holes, slots, and intricate patterns.

The process is highly accurate and can create cuts with a tolerance of up to +/- 0.005 inches. Laser cutting is also a fast and efficient process, with high-speed laser cutting systems capable of cutting through thick quartz glass in a matter of seconds.

Laser cutting custom quartz glass service provides a precise and efficient method for creating complex shapes and designs in quartz glass with high accuracy and repeatability. It is ideal for applications where high purity, high precision, and high-speed production are critical.

How to ensure the precision of the custom laser cutting Quartz glass parts?

Ensuring the precision of quartz glass sheets cut to size service involves several key steps to ensure that the final product meets the desired specifications. Here are some of the key steps involved in ensuring precision in quartz glass cutting:

Accurate measurements:

Accurate measurements of the dimensions of the quartz glass sheet are critical to ensure that the final product meets the desired specifications. This requires using precise measuring tools and techniques, such as laser measurements or digital micrometers.

Choosing the right cutting method:

Different cutting methods may be more suitable for different types of quartz glass and different thicknesses. Choosing the right cutting method, such as laser cutting or water jet cutting, can help ensure precision and accuracy.

High-quality equipment:

Using high-quality cutting equipment, such as CNC cutting machines or precision saws, can help ensure that the cuts are made accurately and consistently.

Proper handling:

Proper handling of the quartz glass sheets during the cutting process is critical to avoid damage or distortion of the material, which can affect the precision of the final product.

Quality control:

Implementing a rigorous quality control process, including regular inspections and testing of the cut quartz glass sheets, can help ensure that the final product meets the desired specifications.

Experienced professionals:

Working with experienced professionals who have expertise in cutting quartz glass can help ensure that the cutting process is performed accurately and efficiently.

Ensuring the precision of quartz glass sheets cut-to-size service requires careful attention to detail and the use of high-quality equipment and techniques. By following these steps, it is possible to achieve high levels of precision and accuracy in the cutting process, resulting in high-quality quartz glass sheets that meet the desired specifications.

What's custom Quartz glass CNC machining fabricate service?

Custom quartz glass CNC machining fabricate service is a process of using computer numerical control (CNC) machines to fabricate custom-designed quartz glass components with high precision and accuracy.

This process involves programming the CNC machine to follow a specific set of instructions to create the desired shape and dimensions of the quartz glass component.

CNC machining is a highly accurate and efficient process that can be used to create a wide range of complex shapes and designs in quartz glass.

The process involves using a cutting tool, such as a drill bit or milling cutter, to remove material from the quartz glass block or sheet to create the desired shape and dimensions.

Custom quartz glass CNC machining fabricate service can be used to create a wide range of components, including lenses, windows, tubes, and other complex shapes.

The process is highly versatile and can be used to create components in various sizes and shapes with high precision and accuracy.

CNC machining is also a fast and efficient process, allowing for high-speed production of custom quartz glass components with consistent quality and accuracy.

This process is ideal for applications where high purity, high precision, and high-speed production are critical, such as in the semiconductor industry.

Overall, custom quartz glass CNC machining fabricate service provides a precise and efficient method for creating complex shapes and designs in quartz glass with high accuracy and repeatability.

It is ideal for applications where high purity, high precision, and high-speed production are critical.

What are the coating types of Quartz glass parts?

Custom quartz glass lenses can be coated with various types of coatings to enhance their performance and functionality in specific applications. Here are some common coating types used for custom quartz glass lenses:

Anti-reflective (AR) coating

This type of coating reduces the amount of light reflected from the surface of the lens, which improves the transmission of light through the lens. This is particularly important for lenses used in optical systems where high transmission of light is critical.

UV-blocking coating

This type of coating blocks ultraviolet (UV) radiation from passing through the lens. This is important for applications where UV radiation can damage sensitive components or cause eye damage.

Anti-scratch coating

This type of coating is designed to protect the lens surface from scratches and other types of damage. This is particularly important for lenses used in harsh environments where the lens surface is exposed to abrasive or corrosive substances.

Hydrophobic coating

This type of coating repels water and other liquids from the surface of the lens. This is important for lenses used in outdoor or wet environments where water droplets can interfere with the performance of the lens.

Oleophobic coating

This type of coating repels oils and other types of liquids from the surface of the lens. This is important for lenses used in environments where oils or other types of contaminants can interfere with the performance of the lens.

Conductive coating

This type of coating is used to create an electrically conductive surface on the lens. This is important for lenses used in applications where electrostatic discharge (ESD) can damage sensitive components.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom quartz glass Parts Into Production Today

Want to save time and money on your quartz glass parts project? Contact us now. Our factory provides high-quality precision custom quartz glass products at very competitive prices and fast production times. We support sample service.