Custom Sapphire Glass Service

High-quality custom Sapphire glass parts supplier at competitive prices.

Contact us now to request a quick quote.

What is Sapphire Glass?

Sapphire glass, also known as synthetic sapphire or sapphire crystal, is a transparent material made from crystalline aluminum oxide (Al2O3), which is chemically very similar to natural sapphire gemstones.

It’s known for its exceptional hardness and scratch resistance, making it a popular choice for various applications that require durability and optical clarity.

Sapphire glass is created through a process called the Verneuil method, or the flame fusion method, where aluminum oxide powder is melted and then allowed to crystallize as it’s slowly cooled.

The resulting crystal structure gives sapphire its impressive mechanical properties.

What are the properties of Sapphire Glass?

Sapphire glass possesses a variety of unique properties that make it valuable for various applications. Here are some of its key properties:

Hardness

Sapphire glass is extremely hard and ranks just below diamond on the Mohs scale of mineral hardness. This hardness gives it exceptional scratch resistance, making it difficult to scratch or damage the surface of sapphire glass.

Transparency

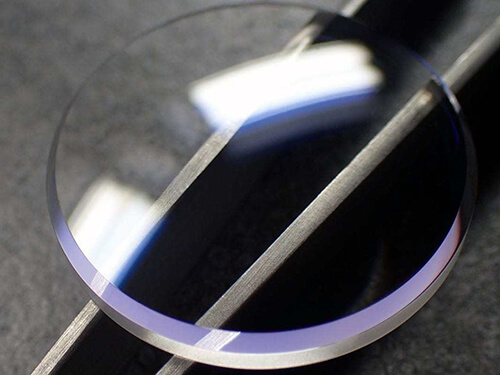

Sapphire glass has excellent optical properties, offering high clarity and transparency across a broad spectrum of wavelengths. It allows light to pass through with minimal distortion, making it suitable for optical and display applications.

Optical Properties

Sapphire glass offers excellent optical transmission properties, with low birefringence and dispersion. It is used in applications where maintaining optical clarity and precision is critical.

Chemical Resistance

Sapphire glass is highly resistant to most chemicals, acids, and alkalis, which contributes to its durability and suitability for use in harsh environments.

Thermal Conductivity

Sapphire glass has relatively high thermal conductivity, allowing it to dissipate heat efficiently. This property is beneficial in applications where temperature control is important.

High Melting Point

Sapphire glass has a high melting point of around 2,040°C (3,704°F), which makes it suitable for use in high-temperature environments without experiencing deformation or degradation.

Electrical Insulation

Sapphire glass is an excellent electrical insulator, which makes it suitable for applications where electrical isolation is required.

Low Coefficient of Thermal Expansion

Sapphire glass has a low coefficient of thermal expansion, meaning it expands and contracts very little with changes in temperature. This property helps prevent warping or cracking when exposed to temperature fluctuations.

Abrasion Resistance

The hardness of sapphire glass contributes to its resistance to abrasion, ensuring that it maintains its optical quality and structural integrity over time, even in demanding environments.

Ultraviolet (UV) Transparency

Sapphire glass is transparent to ultraviolet light, making it suitable for UV-sensitive applications such as certain scientific instruments and UV spectroscopy.

Biocompatibility

Sapphire glass is biocompatible, which means it is well-tolerated by living tissue and can be used in medical devices and implants.

Brittle Nature

While its hardness is an advantage, sapphire glass is also relatively brittle compared to other materials like traditional glass. This brittleness can make it susceptible to shattering or cracking under certain conditions of mechanical stress.

Radio Frequency (RF) Transparency

Sapphire glass has RF transparency, allowing it to be used in applications involving radio frequency signals without significant signal attenuation.

These properties collectively make sapphire glass a sought-after material for various industries and applications where durability, optical quality, and resistance to wear and tear are essential.

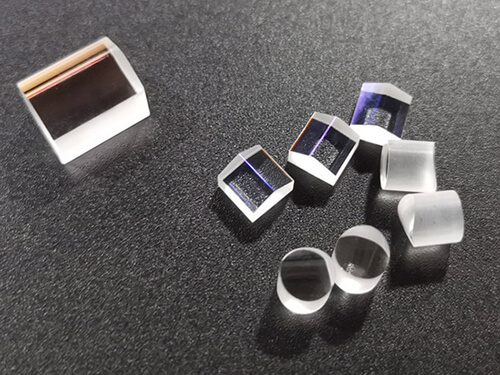

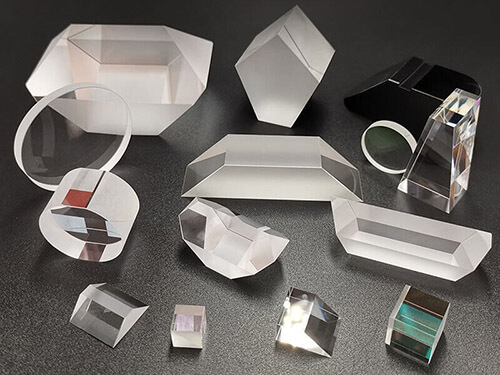

Types of Sapphire Glass?

Sapphire glass comes in different forms and variations, each tailored to specific applications and requirements. Some of the notable types of sapphire glass include:

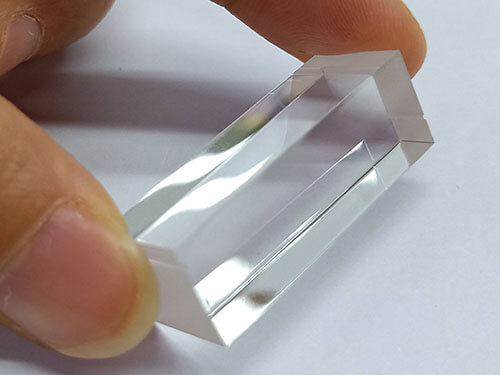

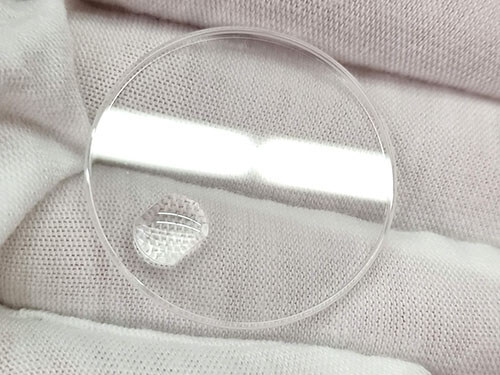

Transparent Sapphire Glass

This is the most common type of sapphire glass, known for its exceptional optical clarity and scratch resistance. It is used in applications where maintaining optical quality is crucial, such as watch crystals, camera lenses, optical windows, and protective covers for electronic devices.

Colored Sapphire Glass

By introducing certain trace elements during the manufacturing process, sapphire glass can be created in various colors, such as blue, yellow, green, and pink. Colored sapphire glass is used in jewelry, decorative items, and specialized optical applications.

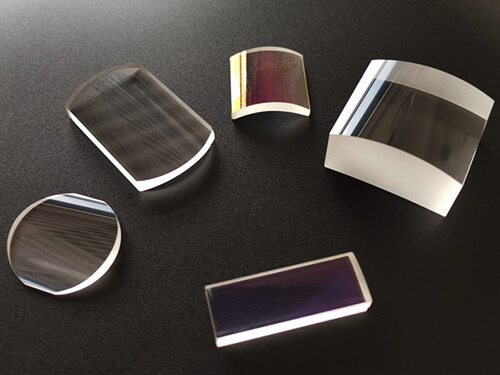

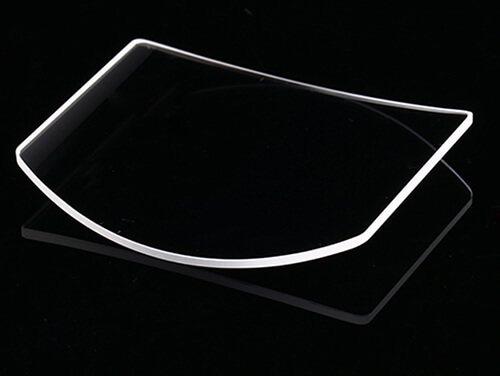

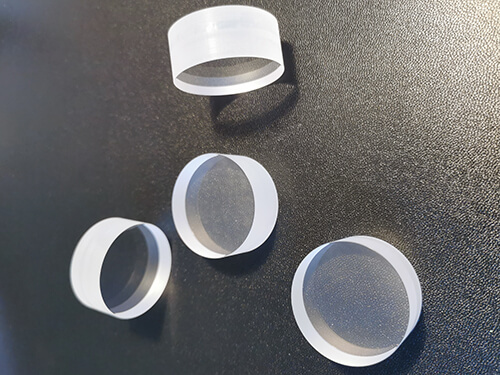

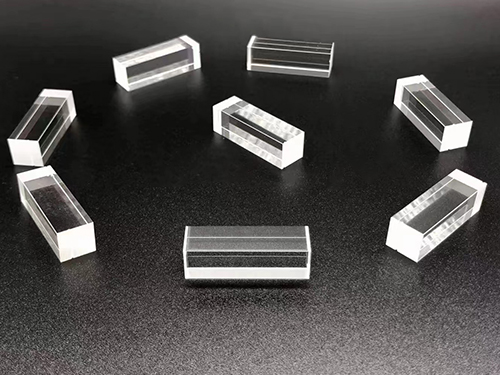

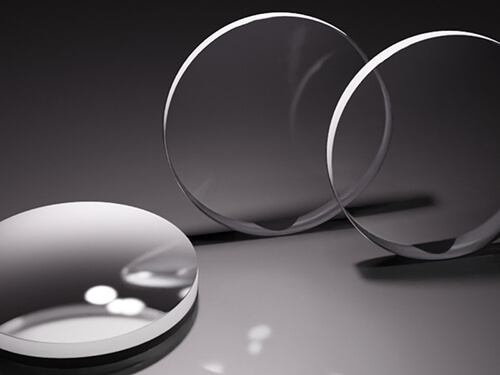

Synthetic Sapphire Windows

These are flat or curved sheets of sapphire glass that are used as optical windows in high-performance equipment, such as laser systems, scientific instruments, and industrial sensors. They provide optical clarity, thermal stability, and resistance to harsh environmental conditions.

Sapphire Substrates

Sapphire glass wafers are used as substrates in the electronics industry, particularly in semiconductor manufacturing. They serve as a stable and durable platform for the growth of thin films and the fabrication of electronic components.

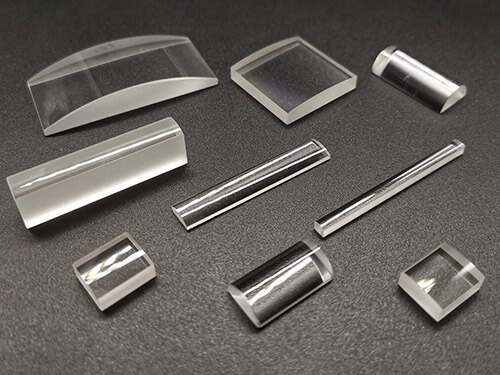

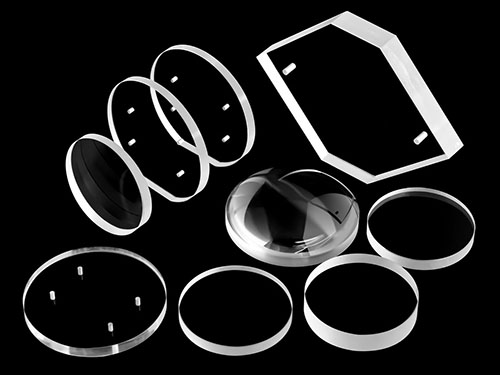

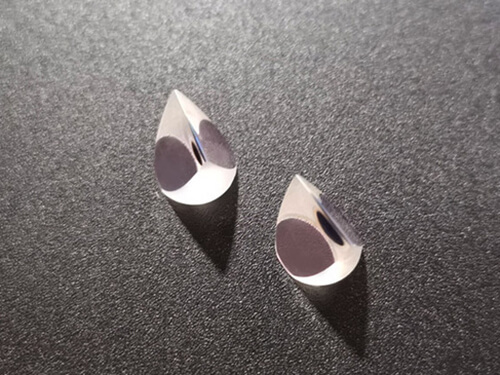

Sapphire Lenses

Sapphire glass can be shaped into lenses for various optical systems, including cameras, microscopes, and lasers. The high optical quality and durability of sapphire lenses make them suitable for demanding applications.

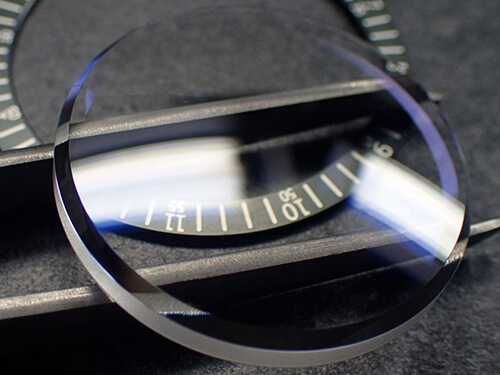

Sapphire Watch Crystals

Many luxury watches use sapphire glass as the crystal covering the watch face. It provides both a clear view of the dial and protection against scratches and impacts.

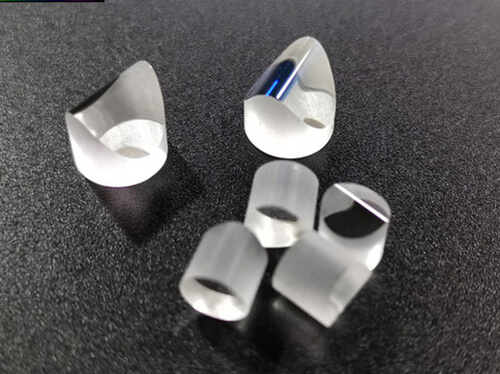

Sapphire Bearings and Nozzles

Due to its low friction and high wear resistance, sapphire glass is sometimes used in bearings, pivots, and nozzles in industrial and scientific equipment.

Sapphire Laser Crystals

Synthetic sapphire crystals are used as laser gain media in solid-state lasers. They offer excellent optical properties and can handle high-power laser beams without damage.

Sapphire Touchscreens

In some high-end devices, sapphire glass is used as a touchscreen surface due to its scratch resistance. However, this application is less common due to cost considerations.

Sapphire Optical Fibers

Sapphire fibers can be used in high-temperature and harsh-environment applications where traditional optical fibers might degrade or melt.

Sapphire Jewelry

While not strictly "glass," synthetic sapphire is used as a gemstone in jewelry, often as an alternative to natural sapphire. It can be cut and polished into various shapes and sizes.

Applications of Sapphire Glass Parts?

Sapphire glass parts find applications in a wide range of industries and technologies due to their exceptional properties. Some of the notable applications include:

Watch Crystals

Sapphire glass is commonly used as the crystal covering for high-end watches. It provides scratch resistance and maintains optical clarity, ensuring the watch face remains pristine.

Optical Windows

Sapphire glass is used as optical windows in various industries, including astronomy, spectroscopy, and high-performance imaging systems.

Semiconductor Manufacturing

Sapphire glass wafers are used as substrates for the growth of gallium nitride (GaN) in LED and semiconductor manufacturing.

Camera Lenses

Sapphire glass is used in camera lenses for smartphones, digital cameras, and professional photography equipment. Its optical clarity and scratch resistance contribute to high-quality images.

Scientific Instruments

Sapphire glass windows are used in scientific instruments, such as spectrometers and optical sensors, where optical transparency and resistance to harsh environmental conditions are essential.

Scientific Instruments

Sapphire glass windows are used in scientific instruments, such as spectrometers and optical sensors, where optical transparency and resistance to harsh environmental conditions are essential.

Lasers

Sapphire glass is employed as laser gain media in solid-state lasers. Its thermal and optical properties make it suitable for generating laser beams in various scientific, industrial, and medical applications.

Medical Devices

Sapphire glass is used in medical devices like endoscopes, surgical lasers, and diagnostic equipment due to its optical clarity, biocompatibility, and resistance to sterilization procedures.

Industrial Sensors

Sapphire glass windows are used in industrial sensors and cameras, where they offer protection against harsh chemicals, high temperatures, and physical impacts.

Electronics Manufacturing

Sapphire glass wafers are used in the production of electronic components, such as LEDs, radio frequency integrated circuits (RFICs), and power electronics.

High-Pressure and High-Temperature Environments

Sapphire glass components are used in high-pressure and high-temperature applications, such as furnaces, chemical reactors, and extreme environment research.

Touchscreen Devices

While less common due to cost considerations, sapphire glass has been used in some touchscreen devices for its scratch resistance.

Military and Defense Applications

Sapphire glass components are used in military optics, targeting systems, and protective visors due to their durability and resistance to damage.

Aerospace and Defense

Sapphire glass windows are used in aircraft, satellites, and military equipment for their ability to withstand high speeds, altitudes, and extreme temperatures without compromising optical performance.

Jewelry

While not a traditional "glass," sapphire gemstones (both natural and synthetic) are used in jewelry, including rings, necklaces, earrings, and bracelets.

Advantages of Sapphire Glass?

Sapphire glass offers a range of advantages that make it a valuable material for various applications. Some of the key advantages include:

Exceptional Hardness

Sapphire glass is one of the hardest known materials, second only to diamond. This extreme hardness provides outstanding scratch resistance, ensuring that surfaces remain pristine even in demanding environments.

Cost-effective

Soda lime glass is a relatively inexpensive material, making it a popular choice in industries where cost is a significant factor.

High Optical Clarity

Sapphire glass has excellent optical properties, including high transparency and minimal light distortion. It allows light to pass through with minimal scattering, making it suitable for applications that require optical precision.

Scratch Resistance

The hardness of sapphire glass contributes to its scratch resistance, making it an ideal choice for products that are prone to wear and tear, such as watch crystals and camera lenses.

Durability

Sapphire glass is highly durable and can withstand physical impacts and mechanical stress without shattering or breaking. This durability is beneficial in applications where the material needs to withstand harsh conditions.

Chemical Resistance

Sapphire glass is highly resistant to most chemicals, acids, and alkalis. This resistance makes it suitable for use in environments where exposure to corrosive substances is a concern.

Thermal Stability

Sapphire glass has a high melting point and excellent thermal conductivity. It can tolerate high temperatures and rapid temperature changes without deforming or degrading.

Biocompatibility

Sapphire glass is biocompatible, which means it is well-tolerated by living tissue. This property makes it suitable for medical applications, such as implants and surgical instruments.

Electrical Insulation

Sapphire glass is a good electrical insulator, making it useful in applications that require electrical isolation.

UV and Infrared Transparency

Sapphire glass is transparent to ultraviolet (UV) and infrared (IR) light, which makes it suitable for applications involving these wavelengths, such as optical windows for specialized sensors.

Low Coefficient of Thermal Expansion

Sapphire glass has a low coefficient of thermal expansion, which means it doesn't expand or contract significantly with temperature changes. This property helps prevent warping and cracking.

Radio Frequency (RF) Transparency

Sapphire glass is transparent to radio frequency (RF) signals, making it suitable for applications involving RF communication or sensing.

Longevity

Due to its resistance to wear, scratching, and environmental factors, products made with sapphire glass tend to have a longer lifespan compared to those made with other materials.

High Value Perception

The use of sapphire glass in luxury watches, high-end smartphones, and other premium products contributes to a perception of quality and luxury.

Environmentally Friendly

The durability and longevity of sapphire glass products can reduce the need for replacements, contributing to reduced waste and resource consumption.

Disadvantages of Sapphire Glass?

While sapphire glass has numerous advantages, it also comes with certain disadvantages that can impact its usability in certain applications. Some of the disadvantages of sapphire glass include:

Cost

Producing sapphire glass is more expensive than manufacturing traditional glass. The process involves growing large single crystals and then cutting and polishing them into the desired shapes. As a result, products made with sapphire glass can be more costly.

Brittleness

Despite its hardness, sapphire glass is relatively brittle compared to some other materials. This brittleness can make it more prone to cracking or shattering when subjected to strong impacts or sudden stresses.

Processing Difficulty

Working with sapphire glass is more challenging than working with traditional glass due to its hardness. Cutting, shaping, and polishing sapphire glass requires specialized equipment and expertise.

Energy Consumption

The production of sapphire glass requires significant energy input, particularly during the crystal growth process. This can contribute to higher energy consumption compared to other manufacturing processes.

Complex Machining

The hardness of sapphire glass makes it more difficult to machine and process compared to other materials. This can increase the complexity and cost of manufacturing products with intricate shapes.

Limited Size

Producing large sheets or pieces of sapphire glass can be challenging and costly due to the growth limitations of the crystal growth process.

Lack of Flexibility for Curved Surfaces

Producing curved sapphire glass surfaces can be challenging and expensive due to the material's rigidity.

What are the coating types of custom Sapphire Glass lenses?

Custom sapphire glass lenses often benefit from various types of coatings that enhance their optical performance, durability, and functionality. Some common coating types for custom sapphire glass lenses include:

Anti-Reflective (AR) Coatings

AR coatings are designed to reduce reflections and increase light transmission through the lens. They help improve image clarity, contrast, and overall optical performance by minimizing unwanted reflections that can cause glare and reduce image quality.

UV Protection Coatings

These coatings can block or reduce ultraviolet (UV) light transmission through the lens. They are especially important for protecting the eyes from harmful UV rays in outdoor and high-exposure environments.

IR (Infrared) Blocking Coatings

IR-blocking coatings are used to filter out or reduce infrared radiation, which can be important for applications where excessive heat buildup needs to be controlled.

Mirror Coatings

Mirror coatings are designed to reflect specific wavelengths of light while allowing other wavelengths to pass through. They are commonly used in applications such as laser optics and optical filters.

The choice of coating types depends on the specific requirements of the lens’s application. Different coatings can be combined to achieve multiple desired effects. Custom sapphire glass lenses are often tailored to the needs of specific industries, such as optics, aerospace, medical devices, and electronics, which determines the selection of coatings to achieve the desired optical performance and functionality.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality Sapphire glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.05~0.1 (mm) to meet your accuracy requirements for the custom Sapphire glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting Sapphire glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom Sapphire glass cut part.

Get Your Custom Sapphire Glass Parts Into Production Today

Want to save time and money on your Sapphire glass parts project? Contact us now. Our factory provides high-quality precision custom Sapphire glass products at very competitive prices and fast production times.