Custom Soda Lime Glass Service

High-quality custom soda lime glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is soda lime glass?

Soda lime glass is a type of glass made by melting together silica (silicon dioxide), sodium carbonate (soda ash), and calcium oxide (lime) at a high temperature.

This type of glass is the most common and widely used glass for a variety of applications, including windowpanes, bottles, jars, and light bulbs.

Soda lime glass is relatively inexpensive and has good optical properties, which makes it ideal for many applications.

It is also easy to shape and can be formed into a variety of shapes and sizes.

Additionally, soda lime glass is relatively strong and durable, but it can still break or shatter under stress.

One disadvantage of soda lime glass is that it has a relatively low resistance to thermal shock, which means that it can crack or break when exposed to rapid temperature changes.

For this reason, it is not suitable for use in high-temperature applications or in situations where it will be exposed to sudden temperature changes.

What are the properties of soda lime glass?

Chemical Properties

Chemical formula: SiO2-Na2O-CaO

Density: 2.4-2.6 g/cm³

Refractive index: 1.5-1.6

Electrical Properties

Electrical resistivity: 10^12-10^18 Ω·cm

Dielectric constant: 7-8

Dielectric strength: 15-30 kV/mm

Thermal Properties

Coefficient of thermal expansion: 8-9 × 10^-6/°C

Softening point: 700-800°C

Annealing point: 460-490°C

Strain point: 420-460°C

Mechanical Properties

Hardness: 5.5-6.5 on the Mohs scale

Tensile strength: 40-100 MPa

Compressive strength: 500-1000 MPa

Elastic modulus: 70-90 GPa

Poisson’s ratio: 0.2-0.25

Physical Properties

Color: colorless or slightly greenish

Can be molded and shaped easily

Has a smooth surface finish

Is relatively inexpensive

Has a low melting point

Optical Properties

Transparent in visible light range

Has a low index of refraction

Can transmit light in the ultraviolet and infrared regions

Has a relatively high light transmission

Types of soda lime glass?

Soda lime glass is a general term that refers to a family of glass types made from a combination of silica (SiO2), soda (Na2O), and lime (CaO). However, there are several different types of soda lime glass that have slightly different compositions and properties. Here are some of the common types of soda lime glass:

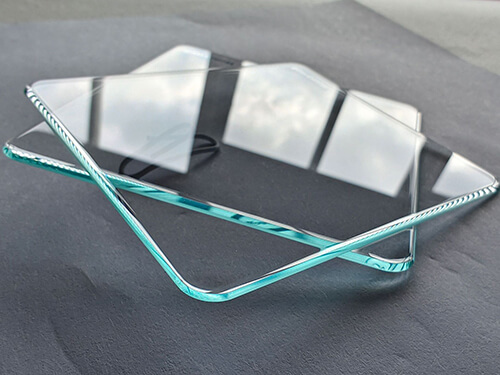

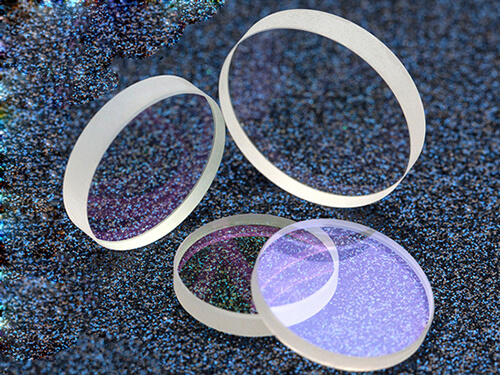

Clear soda lime glass

This is the most common type of soda lime glass, and it is used in a wide range of applications such as windows, bottles, jars, and light bulbs. It is clear and transparent, with a slight greenish tint.

Tempered soda lime glass

This type of soda lime glass is heat-treated to increase its strength and durability. Tempered soda lime glass is often used for safety glass applications, such as automobile windshields, shower doors, and glass table tops.

Low-iron soda lime glass

This type of glass has a reduced iron content, which makes it more transparent and reduces the greenish tint seen in regular soda lime glass. Low-iron soda lime glass is often used in applications where maximum light transmission is required, such as in solar panels or high-end lighting fixtures.

Heat-resistant soda lime glass

This type of glass is formulated to have a higher resistance to thermal shock, making it suitable for use in high-temperature applications such as cookware or laboratory glassware.

Safety soda lime glass

This type of glass is designed to be more shatter-resistant than regular soda lime glass. It is often used in applications such as automotive windshields or safety glass for buildings. If it does break, it tends to break into small, rounded pieces rather than sharp shards, reducing the risk of injury.

Tinted soda lime glass

This type of glass is similar to clear soda lime glass, but it has been treated with a coloring agent to give it a specific color. Tinted soda lime glass is often used in applications where light transmission needs to be reduced, such as in sunglasses or automotive windows.

Applications of soda lime glass cutting service?

Soda-lime glass cutting services can be used in a wide range of applications, as glass cutting allows for the creation of custom shapes and sizes to suit specific needs. Here are some examples of applications where custom soda lime glass parts may be used:

Lighting fixtures

Soda lime glass is often used in lighting fixtures, and cutting services can be used to create custom shades and lens covers for lamps and other light fixtures.

Custom windows and doors

Soda-lime glass cutting services can be used to create custom windows and doors for homes and buildings. This can include everything from standard rectangular shapes to more complex designs with curved or angled edges.

Display cases

Glass display cases are often made from soda lime glass, and cutting services can be used to create custom shapes and sizes to fit specific display items.

Art and decorative pieces

Soda lime glass can be cut and shaped to create unique art and decorative pieces such as mirrors, sculptures, and vases.

Automotive glass

Soda lime cutting services can be used to create custom windshields, windows, and mirrors for cars and other vehicles.

Laboratory glassware

Soda lime glass is often used in laboratory glassware, and cutting services can be used to create custom shapes and sizes to fit specific experimental setups.

What advantages of custom soda lime glass parts?

Soda-lime glass is a popular material in various industries due to its advantages. Here are some advantages of soda lime glass:

Transparency

Soda lime glass is highly transparent, allowing for maximum light transmission. This makes it ideal for use in applications such as windows, light bulbs, and solar panels.

Cost-effective

Soda lime glass is a relatively inexpensive material, making it a popular choice in industries where cost is a significant factor.

Easy to manufacture

Soda lime glass is relatively easy to manufacture compared to other types of glass. This makes it a popular choice for large-scale production.

Chemical resistance

Soda lime glass is resistant to most chemicals, making it an ideal material for laboratory glassware and other applications where chemical resistance is important.

Thermal shock resistance

Soda-lime glass has good thermal shock resistance, meaning it can withstand sudden changes in temperature without breaking. This makes it ideal for use in applications where high temperatures are involved, such as cookware.

Versatile

Soda lime glass is a versatile material that can be used in a wide range of applications across various industries. Its properties can be modified to suit specific needs, making it a popular choice for custom applications.

What're disadvantages of custom soda lime glass parts?

While soda lime glass has many advantages, there are also some disadvantages. Here are some of the disadvantages of soda lime glass:

Relatively low strength

Compared to other types of glass, such as borosilicate glass, soda lime glass is low in strength. It is more prone to cracking and breaking under stress, which may limit its use in some applications.

Limited chemical resistance

Although soda lime glass is generally resistant to most chemicals, it is not as resistant as other types of glass, such as borosilicate glass. This may limit its use in some laboratory applications.

Limited thermal resistance

While soda lime glass has good thermal shock resistance, it has a lower maximum temperature limit than some other types of glass. This may limit its use in some high-temperature applications.

Brittle

Soda lime glass is relatively brittle, which means that it is more prone to cracking or breaking upon impact. This may limit its use in applications where impact resistance is important.

These are some of the disadvantages of soda lime glass that should be considered when selecting a material for a specific application. However, it’s worth noting that despite these limitations, soda lime glass is still widely used in various industries due to its unique properties and affordability.

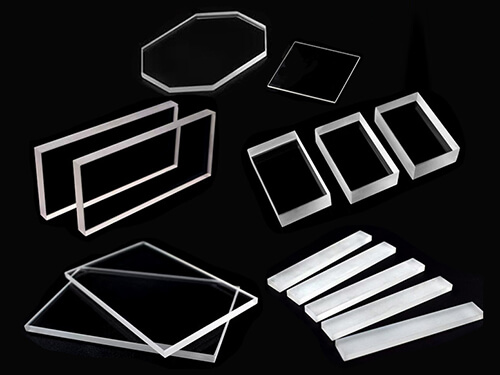

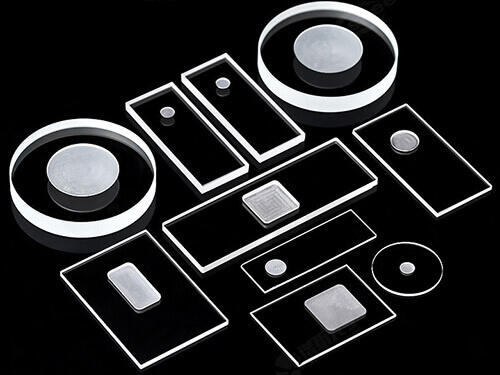

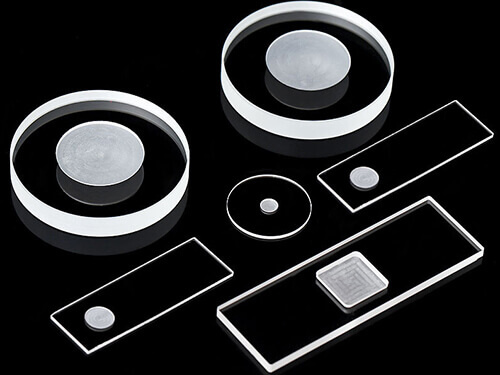

Custom Soda Lime Glass Parts We Can Manufacture

- Frosted Glass Lens

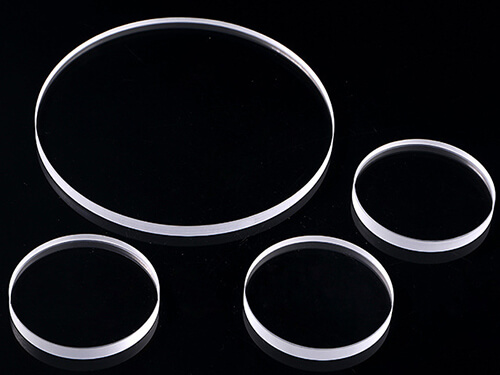

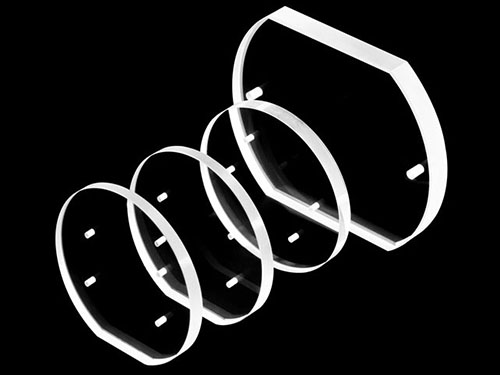

- Round Sight Glass

- Touch Switches

- Touch Glass

- Glass Touch Panel

- Display Glass

- Tempered Glass Panel

- Smart Switch

- Circular Sight Glass

- Sight Glass Window

- Solar Panel Glass

- Electrical Glass

- Flashlight Glass Lens

- Silk Printing Glass Panel

- Anti-Glare Glass Lens

- High Transparent Lens

- Monitoring Lenses

- Optical Instruments

- Industrial Sight Glass

- Switch Panel Glass

- Pipeline Sight Glass

- Boiler Window Glass

- Quartz Glass Sight Glass

- Heat-insulating Glass

What's custom soda lime glass laser cutting service?

Laser cutting custom soda lime glass service is a process in which a laser beam is used to cut soda lime glass into custom shapes and sizes.

The laser beam is directed onto the glass, which melts or vaporizes the material, creating a precise cut with minimal waste.

Laser cutting custom soda lime glass service is often used to create intricate designs and shapes that would be difficult or impossible to achieve with traditional cutting methods.

This service is commonly used in the production of glassware, lighting fixtures, and decorative items, among other applications.

One of the advantages of laser cutting custom soda lime glass service is that it can produce very precise cuts with minimal chipping or cracking.

This means that the glass can be cut into complex shapes and designs without compromising its structural integrity.

Another advantage of laser cutting custom soda lime glass service is that it can be used to cut thick glass with ease.

This makes it a popular choice for cutting glass panels and other large pieces of glass.

It can produce high-quality cuts quickly and efficiently, making it a popular choice for custom glass fabrication.

How to ensure the precision of the custom laser cutting soda lime glass parts?

To ensure the precision of the soda lime glass sheets cut-to-size service, there are several factors that should be considered:

Accurate measurements:

Accurate measurements of the glass sheets are critical to ensure that the final product is cut to the desired size. To achieve this, precise measuring tools should be used, and measurements should be taken multiple times to ensure consistency.

Quality of the cutting equipment:

The quality of the cutting equipment used is also important in ensuring the precision of the cut. High-quality cutting equipment, such as laser cutters or waterjet cutters, can produce precise cuts with minimal waste.

The expertise of the operators:

The expertise of the operators who perform the cutting is another crucial factor in ensuring the precision of the cut. Experienced operators who are knowledgeable in the cutting process can make adjustments and fine-tune the cutting parameters to achieve the desired result.

Quality control measures:

Quality control measures, such as inspecting the cut pieces for accuracy and consistency, should be implemented to ensure that the final product meets the desired specifications.

Material selection:

The quality and consistency of the soda lime glass sheets being used should also be considered. The sheets should be of high quality and consistent thickness to ensure that the final product is cut to the desired size and shape.

By considering these factors and taking appropriate steps, the precision of the soda lime glass sheets cut-to-size service can be ensured, resulting in high-quality and accurate final products.

What's custom soda lime glass CNC machining fabricate service?

Custom soda lime glass CNC machining fabricate service is a process in which soda lime glass is machined into custom shapes and sizes using computer-controlled machines.

CNC (Computer Numerical Control) machines use a series of programmed instructions to control the cutting tools, allowing for precise and accurate cuts to be made.

In the custom soda lime glass CNC machining fabricate service, the glass is placed onto the CNC machine’s work surface, and the cutting tool is programmed to move in a specific pattern to cut the glass to the desired shape and size.

The cutting tool can be a diamond-tipped drill, a router bit, or a saw blade, depending on the specific requirements of the project.

One of the advantages of custom soda lime glass CNC machining fabricate service is that it can produce very precise cuts with minimal waste.

This means that the glass can be cut into complex shapes and designs without compromising its structural integrity.

Another advantage of the custom soda lime glass CNC machining fabricate service is that it can be used to create three-dimensional shapes and contours.

This makes it a popular choice for creating complex glass parts and components for various applications, including optics, electronics, and medical devices.

Custom soda lime glass CNC machining fabricate service is a versatile and precise machining method that is widely used in various industries.

It can produce high-quality custom glass parts quickly and efficiently, making it a popular choice for custom glass fabrication.

What are the coating types of soda lime glass parts?

There are several types of coatings that can be applied to custom soda lime glass lenses to enhance their performance and durability:

Anti-reflective (AR) coating

AR coatings reduce reflection and glare, improving the clarity and brightness of the lens. They are commonly used in eyeglasses and camera lenses.

Hard coating

Hard coatings are applied to the surface of the lens to improve its durability and resistance to scratches, abrasion, and other damage. They are commonly used in industrial and medical applications.

Anti-fog coating

Anti-fog coatings prevent the lens from fogging up, improving visibility in humid or cold conditions. They are commonly used in sports goggles and safety glasses.

UV coating

UV coatings block harmful UV rays from reaching the eyes, protecting them from damage. They are commonly used in sunglasses and outdoor eyewear.

Color coating

Color coatings are used to change the appearance of the lens, making it more aesthetically appealing or enhancing its contrast or visibility. They are commonly used in fashion eyewear and sports goggles.

The specific coating type used for custom soda lime glass lenses will depend on the intended application and the desired performance characteristics. A combination of different coatings may also be used to achieve multiple benefits.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.1~0.05 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Custom Soda-lime Glass Parts Into Production Today

Want to save time and money on your Soda-lime glass parts project? Contact us now. Our factory provides high-quality precision custom Soda-lime glass products at very competitive prices and fast production times. We support free sample service.