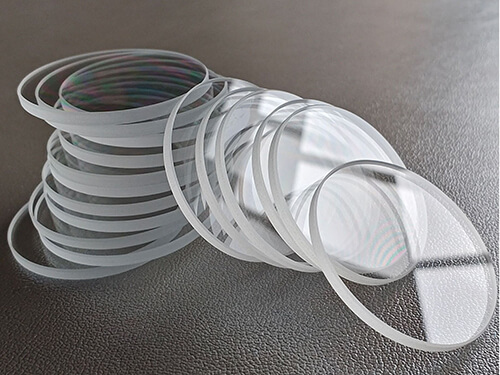

Custom tempered glass Service

High-quality custom tempered glass parts supplier at competitive prices.

Contact us now to request a quick quote or get a free sample

What is tempered glass?

Tempered glass is a type of safety glass that is processed by heating a standard sheet of glass to a high temperature and then rapidly cooling it using a process known as “quenching.”

This process creates a glass that is stronger and more durable than standard glass.

During the quenching process, the outer surfaces of the glass cool much more quickly than the center, creating a state of tension in the glass.

This tension makes tempered glass more resistant to impacts and thermal shock, and also makes it more resistant to breaking into sharp, jagged pieces.

What are the properties of tempered glass?

Electrical Properties

Tempered glass is an electrical insulator and can be used in applications where electrical conductivity is not desired. It also has good dielectric properties, which means that it can store electrical charge without discharging it.

Mechanical Properties

Tempered glass is much stronger and more durable than regular glass. It has a higher tensile strength, which means it can resist greater forces without breaking. Tempered glass is also more resistant to impact, bending, and torsion than regular glass.

Chemical Properties

Tempered glass is made from regular glass that is heated to a very high temperature and then rapidly cooled. This process, called quenching, creates a layer of compressive stress on the surface of the glass, which makes it more resistant to chemical attack than regular glass.

Thermal Properties

Tempered glass has high thermal resistance and can withstand sudden temperature changes without breaking. The tempering process creates a layer of compressive stress on the surface of the glass, which makes it more resistant to thermal stress. The thermal conductivity of tempered glass is also lower than that of regular glass.

Physical Properties

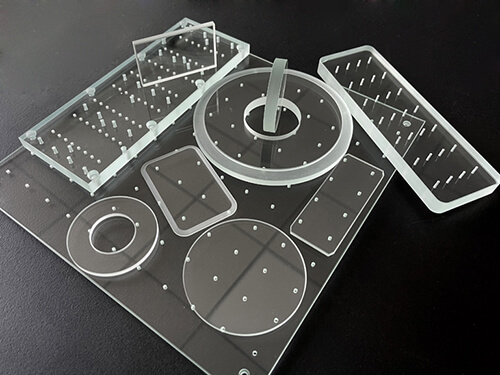

Tempered glass is thicker and heavier than regular glass, but it is also more durable and resistant to breakage. It is available in a range of thicknesses and can be cut, drilled, and shaped to fit a wide range of applications. Tempered glass is also easy to clean and maintain, and it resists staining and discoloration over time.

Optical Properties

Tempered glass has similar optical properties to regular glass, but it is more resistant to scratching and other forms of wear and tear. It also has a higher refractive index than regular glass, which means that it bends light more and can be used in applications where optical clarity is important.

Types of tempered glass?

There are several types of tempered glass, each with unique properties and applications. Here are some of the most common types:

Clear tempered glass

This is the most common type of tempered glass, and it has a clear, transparent appearance. It is often used in windows, doors, and other applications where visibility is important.

Low-E tempered glass

Low-emissivity tempered glass has a special coating that reflects heat and UV rays, making it more energy-efficient. It is often used in windows, doors, and other applications where energy efficiency is important.

Frosted tempered glass

Frosted tempered glass has a rough, textured surface that diffuses light and provides privacy. It is often used in shower doors, bathroom windows, and other applications where privacy is important.

Printed tempered glass

Printed tempered glass has a decorative pattern or design printed on its surface. It is often used in interior design applications such as partitions, dividers, and backsplashes.

Curved tempered glass

Curved tempered glass is formed using a special bending process, which gives it a curved shape. It is often used in architectural applications such as building facades, canopies, and skylights.

Tinted tempered glass

This type of tempered glass has a colored tint that reduces glare and heat transmission. It is often used in car windows, skylights, and other applications where heat and light control are important.

Applications of custom tempered glass service?

The custom tempered glass plate, panel, and lens cutting service find applications in various industries that require safety, durability, and optical clarity. The custom tempered glass plate, panel, and lens cutting service have many applications across various industries. Some of the most common applications include:

Electronics Industry

Tempered glass panels are used as screens for smartphones, tablets, and laptops. They also find application in LCD screens, touchscreens, and display panels.

Lighting Industry

Tempered glass is used in the production of lenses and covers for LED lights. It provides protection against the elements and enhances the light diffusion.

Medical Industry

Tempered glass is used in the production of medical equipment, such as X-ray machines, CT scanners, and surgical instruments. It provides durability and safety to the users.

Automotive Industry

Custom tempered glass is used in car windows, windshields, and mirrors. It provides safety and durability to the driver and passengers.

Construction and Architecture

Custom tempered glass panels can be used in building facades, curtain walls, skylights, stair treads, and railings. They can also be used as glass partitions to separate rooms or create office cubicles.

Food Industry

Tempered glass is used in the production of kitchen appliances, such as ovens, cooktops, and refrigerators. It is also used in commercial kitchens as countertops and splashbacks.

Furniture Industry

Tempered glass is used in the production of glass tables, shelves, and cabinets. It provides durability and safety to the users.

What advantages of custom Tempered glass parts?

Tempered glass is a versatile and durable material that is ideal for use in a wide range of applications where safety, strength, and durability are important considerations. Some advantages of tempered glass include:

Safety

Tempered glass is much safer than regular glass because it shatters into small, rounded pieces rather than sharp shards when broken. This reduces the risk of injury in the event of an accident.

Strength

Tempered glass is much stronger than regular glass, making it more resistant to impact and thermal stress. This makes it a popular choice for use in high-traffic areas or in situations where glass is at risk of being bumped or hit.

Scratch-resistant

Tempered glass is more scratch-resistant than regular glass, making it ideal for use in applications where the glass may be subject to wear and tear, such as smartphone screens or kitchen countertops.

Heat-resistant

Tempered glass can withstand high temperatures without cracking or breaking. This makes it a popular choice for use in applications where heat resistance is important, such as oven doors or fireplace screens.

Durability

Tempered glass is resistant to chemical and environmental factors, making it durable and long-lasting.

What're disadvantages of tempered glass?

While tempered glass has many advantages, there are also some disadvantages to consider. These include:

Limited customization

Tempered glass cannot be cut or drilled after it has been tempered, which means that it must be cut to the correct size and shape before the tempering process. This limits the customization options for tempered glass.

Cost

Tempered glass is more expensive than regular glass due to the additional processing required to make it. This can make it a less attractive option for some applications where cost is a primary concern.

Fragments can still be dangerous

While tempered glass is much safer than regular glass, it can still break and produce small, rounded fragments that can be sharp and potentially dangerous. While the risk of injury is reduced compared to regular glass, it is still important to handle tempered glass with care.

Limited thermal resistance

While tempered glass can withstand sudden temperature changes without breaking, it has a limited thermal resistance compared to other types of glass. This means that it may not be suitable for use in applications where extremely high temperatures are expected.

Tempered glass is a strong and durable material with many advantages, but its limitations should be carefully considered when choosing the right type of glass for a particular application.

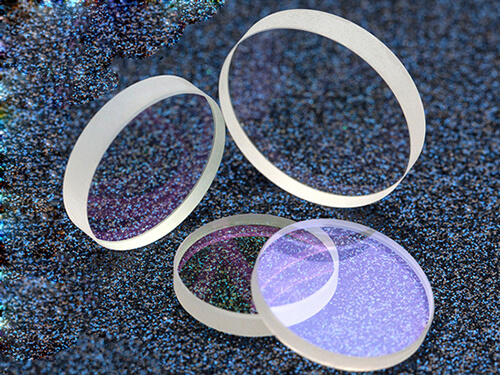

What are the coating types of custom tempered glass parts?

Custom tempered glass lenses can be coated with a variety of coatings to enhance their performance and improve their optical properties. Some common coating types for custom tempered glass lenses include:

Anti-reflective (AR) coatings

These coatings reduce glare and reflections on the surface of the lens, improving the clarity and brightness of the image.

Scratch-resistant coatings

These coatings help protect the surface of the lens from scratches and other types of damage, improving the durability and longevity of the lens.

UV-blocking coatings

These coatings filter out harmful ultraviolet (UV) rays from the sun, protecting the eyes and skin from damage.

Oleophobic coatings

These coatings repel oil and other types of contaminants, making the lens easier to clean and reducing the likelihood of smudging or staining.

Hydrophobic coatings

These coatings repel water and other liquids, making the lens easier to clean and reducing the likelihood of smudging or staining.

Color coatings

These coatings can add a specific color tint to the lens, improving contrast or reducing glare in certain lighting conditions.

The specific type of coating used will depend on the intended application of the custom tempered glass lens and the desired optical properties.

By selecting the right coating type, custom tempered glass lenses can be optimized for a wide range of applications, including eyewear, camera lenses, and optical instruments.

Why More Than 1500+ Clients ♥️ HY

Save Cost

We will reduce your 40%-80% purchase cost by investing in high-quality glass machining machines, improving production efficiency, and purchasing raw materials in bulk.

Ultra Quality

Our QC department combines the most advanced technology and experienced professionals to ensure strict inspection and 100% compliance with your requirements and specifications.

Precision Machining

Our tolerances are between +/-0.1~0.05 (mm) to meet your accuracy requirements for the custom glass parts. Our ultra-modern machining technology can meet your tight request for custom-cutting glass parts.

Expertise Engineer Team

Our full-experience engineering team provides technical consultation, pre-review of drawings, structural analysis, risk assessment, design suggestions, and cost analysis to ensure accuracy and save the cost for you.

Fast Delivery

Samples time can be as fast as 3 business days. Mass production time can be as fast as 5 business days. Our advanced equipment and streamlined production process will meet your urgent time request.

No MOQ

You won't face MOQ problems with us. We never require a minimum order volume or minimum dollar value. We'll help you to achieve your goal even if you only need 1 pc custom glass cut part.

Get Your Customtempered Glass Parts Into Production Today

Want to save time and money on your tempered glass parts project? Contact us now. Our factory provides high-quality precision custom tempered glass products at very competitive prices and fast production times. We support free sample service.