Sapphire glass, renowned for its exceptional hardness and clarity, has become a material of choice across various industries, from electronics to optics and watchmaking. One crucial aspect that significantly influences its performance and durability is surface quality.

In this article, we will delve into the intricate details of surface quality specifications for sapphire glass and explore why it matters in diverse applications.

What is Sapphire Glass?

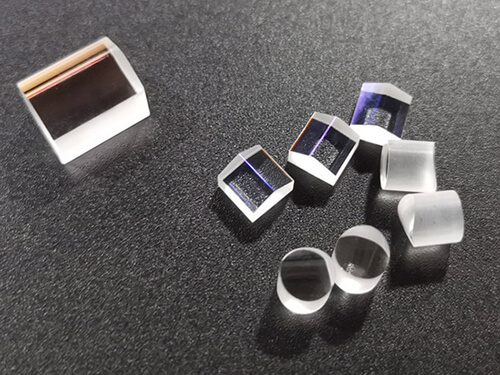

Sapphire glass is a synthetic material known for its remarkable hardness, second only to diamonds. Composed of crystalline aluminum oxide, sapphire glass exhibits high transparency in the visible light spectrum, making it ideal for optical applications. Its robustness against scratches and abrasions has led to widespread use in smartphones, camera lenses, medical devices, and luxury watches.

Significance of Surface Quality

The allure of sapphire glass lies not only in its inherent hardness but also in its optical clarity. Surface quality plays a pivotal role in maintaining these desirable characteristics. Even minor imperfections on the surface can compromise the functionality and aesthetics of sapphire glass. Whether it’s a smartphone screen or a precision optical lens, a flawless surface is imperative for optimal performance.

Surface Quality Specifications

Manufacturers adhere to stringent surface quality specifications to ensure the reliability and functionality of sapphire glass products. These specifications are often standardized within the industry and are crucial for determining the quality of the final product. Common specifications include surface roughness, scratch-dig criteria, and the presence of any visible defects.

Surface Roughness

Surface roughness is a measure of the irregularities on the surface of sapphire glass. It is typically expressed in terms of Ra (average roughness) or Rz (maximum peak-to-valley height). Lower roughness values indicate a smoother surface, contributing to improved optical clarity and reduced light scattering.

Scratch-Dig Criteria

The scratch-dig criteria define the allowable levels of scratches and digs on the surface of sapphire glass. It is expressed as a combination of two numbers, where the first represents the allowable scratch dimensions, and the second represents the allowable dig dimensions. A lower scratch-dig specification indicates a higher-quality surface.

Visible Defects

Visible defects encompass any irregularities that are perceptible to the naked eye. These may include bubbles, inclusions, or other anomalies that can affect the transparency of sapphire glass. Stringent specifications aim to limit or eliminate these defects, ensuring a pristine appearance.

Measurement and Inspection

Accurate measurement and inspection methods are crucial for ensuring that sapphire glass meets the specified surface quality criteria. Advanced technologies such as interferometry and optical inspection systems are employed to assess surface characteristics with precision. Manufacturers invest in these tools to maintain consistency and reliability in their products.

Factors Influencing Surface Quality

Several factors can influence the surface quality of sapphire glass during the manufacturing process. The choice of raw materials, fabrication techniques, and environmental conditions all play a role in determining the final surface quality. Understanding and controlling these factors are essential for achieving the desired specifications.

In conclusion, understanding the surface quality specifications of sapphire glass is paramount for harnessing its full potential across various industries. Whether it’s enhancing the durability of consumer electronics or optimizing the performance of optical instruments, manufacturers must prioritize surface quality to deliver products that meet the highest standards. As technology advances and applications for sapphire glass continue to expand, the meticulous attention to surface quality will remain a cornerstone of product excellence.

To explore high-quality sapphire glass products that meet stringent surface quality specifications, HY invites you to browse our range of offerings. Contact our team for more information on how our sapphire glass solutions can elevate your applications.

HY offers a range of OEM custom sapphire glass solutions tailored to your specific needs.

Contact us to learn more about how we can provide the ideal sapphire glass solution for your industry-leading products.

Email: wendy@hylasercutting.com