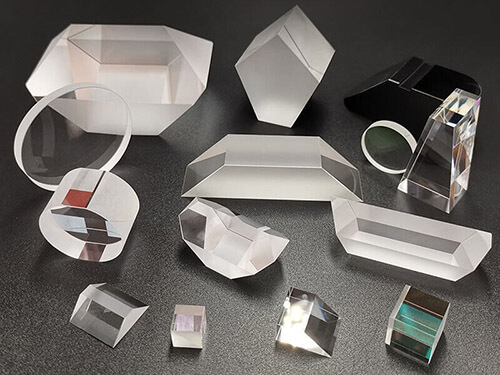

Custom sapphire glass parts are high-performance components manufactured primarily from synthetic sapphire, a durable and scratch-resistant material created from aluminum oxide.

This glass is extensively used across various industries, including consumer electronics, aerospace, healthcare, and luxury goods, due to its exceptional optical clarity and mechanical strength.

The notable properties of sapphire glass make it a preferred choice for applications such as smartphone screens, watch crystals, and advanced optical devices, underscoring its significance in both everyday and specialized products.

The manufacturing process for custom sapphire glass parts is intricate and involves several stages, including the synthesis of synthetic sapphire, cutting and shaping, grinding, polishing, and rigorous quality control measures.

The synthesis typically takes place in high-temperature vacuum furnaces, while subsequent processing steps utilize precision machinery to achieve the desired specifications.

As demand for these parts grows, particularly in the booming consumer electronics market, companies face challenges related to high production costs, supply chain disruptions, and competition from alternative materials like Gorilla Glass.

Geographically, the production of sapphire glass is concentrated in major regions, including North America, Europe, and Asia Pacific, each contributing to the global market in distinct ways.

North America is a leader in sapphire glass for electronics and defense applications, while Europe is notable for its luxury goods market. Meanwhile, Asia Pacific is experiencing rapid growth in sapphire glass production due to the expansion of manufacturing capabilities in countries like China and Japan.

The diverse applications of sapphire glass are expanding, prompting investments in new technologies and processes that enhance production efficiency and sustainability practices within the industry.

Despite its advantages, the sapphire glass industry grapples with several controversies, particularly surrounding its high costs and the environmental impacts of its manufacturing processes.

Additionally, limited awareness of its potential in emerging sectors poses barriers to broader adoption.

As the market evolves, technological advancements and a growing emphasis on sustainability are expected to shape the future of custom sapphire glass parts, ensuring their continued relevance across various sectors.

Manufacturing Process of Custom Sapphire Glass

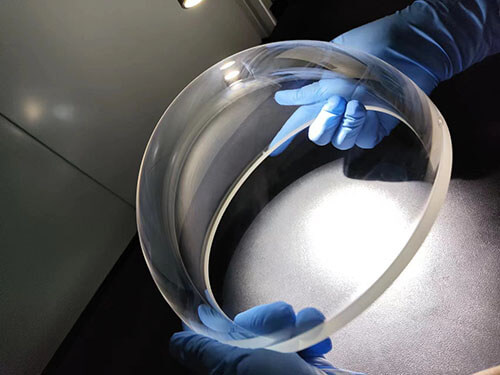

The manufacturing process of custom sapphire glass parts involves several intricate steps designed to produce high-quality, durable products suitable for various applications.

This process typically begins with the selection of raw materials, primarily aluminum oxide (alumina), which is then subjected to high temperatures to create synthetic sapphire.

The molten alumina is melted in a vacuum furnace at temperatures ranging from 2000 to 2200 degrees Celsius, allowing for the desired purity and crystallization of the material.

Synthetic Sapphire Synthesis

The initial step, synthetic sapphire synthesis, involves melting alumina to form a single crystal. The molten material is then cooled and crystallized, creating a sapphire block that can be shaped and cut as needed.

This block is essential for producing components that require high durability and scratch resistance, such as watch faces, smartphone screens, and camera lenses.

Cutting and Shaping

Once the sapphire block is formed, it undergoes cutting and shaping using diamond-tipped cutting tools.

Techniques such as CNC machining are employed to achieve precise dimensions and complex geometries.

This method allows for high accuracy and fine surface finishes, which are critical for optical clarity in applications like electronics and optics.

Grinding and Polishing

After cutting, the sapphire components are ground and polished to achieve the desired thickness and smoothness.

Polishing can be accomplished through various methods, including diamond polishing and chemical polishing, which involve the use of diamond pastes or acid mixtures to create a reflective surface.

The rigorous grinding and polishing stages are crucial for ensuring that the final product meets strict quality standards.

Quality Control and Customization

Throughout the manufacturing process, HY implements strict quality control measures to ensure that each component meets the required specifications.

This includes inspecting the sapphire for defects and ensuring its optical properties are consistent with customer expectations.

Customization options are also available, allowing clients to specify unique shapes and functionalities tailored to their needs.

The culmination of this complex manufacturing process results in sapphire glass parts that are not only aesthetically pleasing but also exceptionally durable, making them suitable for high-demand industries such as aerospace, defense, telecommunications, and healthcare.

As manufacturing techniques continue to advance in HY, the production of sapphire glass becomes more cost-effective and accessible across various sectors, driving broader adoption of this innovative material.

Major Manufacturing Regions Of Sapphire Glass

North America

North America is a leading market for sapphire glass, driven by the presence of major manufacturers and a strong demand across various sectors such as aerospace, defense, and luxury goods.

The United States, in particular, accounts for the majority of sapphire demand within the region due to ongoing government investments in defense technology and the need for high-performance materials that can withstand extreme conditions.

Companies like Apple and Corning Inc. are key players in the North American market, actively investing in advanced manufacturing technologies to meet the increasing demand for durable sapphire glass products in electronics and luxury items.

Europe

The European sapphire glass market benefits from a robust manufacturing base and a thriving luxury goods sector.

The applications of sapphire glass in high-end watches, jewelry, and specialty electronics align with the region’s emphasis on quality and durability.

Switzerland, a major hub for luxury watch manufacturing, extensively uses sapphire crystals due to their scratch-resistant properties. Notably, renowned brands such as Swatch Group and Richemont heavily rely on sapphire glass for their watch models, reinforcing Europe’s standing in the global sapphire market.

Additionally, recent initiatives aimed at enhancing sustainability in sapphire glass production are expected to reduce the carbon footprint of manufacturing processes by 15% over the next five years.

Asia Pacific

The Asia Pacific region is experiencing rapid growth in the sapphire glass market, primarily due to the expansion of consumer electronics manufacturing hubs in countries such as China, Japan, and South Korea.

This growth is supported by rising urbanization and industrialization, alongside the development of the semiconductor industry. Both India and China are projected to emerge as major contributors to the market, demonstrating a compound annual growth rate (CAGR) that outpaces other regions.

Furthermore, the increasing adoption of sapphire glass in various applications, including smartphones and LED screens, highlights the region’s significant role in the global market.

Middle East and Africa

Emerging markets in the Middle East and Africa are also contributing to the growth of the sapphire glass industry, driven by rising investments in industrial applications and a growing demand for high-performance materials in sectors such as construction and healthcare.

This region presents lucrative opportunities for market players looking to tap into underexplored segments and capitalize on the increasing demand for advanced materials.

Latin America

The Latin American sapphire glass market is similarly gaining traction, bolstered by rising industrial activities and the adoption of advanced materials.

As economies in the region continue to develop, the demand for sapphire glass in various applications is expected to increase, providing additional growth opportunities for manufacturers and suppliers.

Applications of Custom Sapphire Glass

Custom sapphire glass parts are utilized across a variety of industries due to their exceptional properties, such as high hardness, scratch resistance, and excellent optical clarity. These characteristics make sapphire glass an ideal material for several applications, which are outlined below.

Optics

Sapphire glass is extensively used in optical applications, including lenses and windows, thanks to its high refractive index and excellent transmission of light.

It is employed in various optical devices such as scientific instruments, high-performance imaging systems, and even in fields like astronomy and spectroscopy, where clarity and durability are paramount.

Aerospace and Defense

The aerospace and defense sectors have increasingly adopted sapphire glass for applications requiring high durability and performance under extreme conditions.

For instance, sapphire glass is used in aircraft sensor protection systems and missile guidance systems, where its ability to endure harsh environments is critical.

The U.S. Air Force has begun integrating sapphire glass into advanced aircraft systems, highlighting its growing significance in these fields.

Watch Crystals

One of the most notable applications of custom sapphire glass is in the manufacture of watch crystals.

High-end watches often feature sapphire glass due to its durability and scratch-resistant nature, ensuring that the watch face remains pristine even under everyday wear conditions.

The use of sapphire crystal can significantly enhance the perceived value of luxury timepieces, as it is regarded as a premium material compared to alternatives like mineral or acrylic glass.

Consumer Electronics

In the realm of consumer electronics, sapphire glass serves as a protective cover for camera lenses and touchscreens in smartphones and other devices.

Its scratch resistance and optical clarity make it a preferred choice for enhancing the durability and functionality of these gadgets, ensuring they can withstand the rigors of daily use.

Medical Devices

In medical technology, sapphire glass is utilized in various applications, including surgical instruments, endoscope lenses, and laser hair removal systems.

Its durability and biocompatibility enhance the performance and longevity of medical devices, making it a valuable material in the healthcare industry.

Semiconductor Manufacturing

Sapphire glass wafers are also employed as substrates for the growth of gallium nitride (GaN) in LED and semiconductor manufacturing.

This application takes advantage of sapphire’s properties to facilitate the production of high-quality electronic components.

Through these diverse applications, custom sapphire glass parts demonstrate versatility and functionality, making them an essential material across multiple industries.

Challenges in Manufacturing of Sapphire glass

The manufacturing of custom sapphire glass parts faces several significant challenges that can impact production efficiency and market adoption.

Supply Chain Disruptions

Supply chain disruptions have been a notable issue across various sectors, including sapphire production and distribution.

The global nature of sapphire supply chains means that restrictions or delays in one region can have widespread consequences.

Challenges such as delays in raw material procurement, transportation bottlenecks, and workforce shortages hinder the timely delivery of sapphire products, forcing companies to diversify their supply chains and explore local sourcing options to mitigate these issues.

High Production Costs

The cost and complexity associated with sapphire production are significant barriers.

The processes required to manufacture high-quality synthetic sapphire, particularly through methods like the Kyropoulos technique, are labor-intensive and expensive.

These high production costs can translate into elevated prices for final products, limiting the accessibility of sapphire for various applications, particularly in budget-sensitive markets.

Competition from Alternative Materials

Intense competition from alternative materials poses a further challenge for the sapphire industry.

In consumer electronics, materials like Gorilla Glass offer comparable durability and performance at a lower price point, leading many manufacturers to opt for these alternatives.

The increasing innovation in glass and ceramics further enhances the competitive landscape, necessitating that the sapphire industry demonstrates clear advantages to justify its higher costs

Machining and Processing Difficulties

Sapphire glass is harder and more brittle than traditional materials, which complicates cutting and processing.

This inherent material property adds complexity to its application in industries that require precise customization, limiting its widespread use and adoption in some sectors.

Despite advances in manufacturing techniques, the machining and processing of sapphire remain challenging and may deter manufacturers from choosing this material for their products.

Limited Industry Awareness

Another challenge is the limited awareness of sapphire’s potential across certain industries.

While its applications in electronics and luxury goods are well-known, its potential in emerging sectors, such as healthcare, remains underutilized.

This lack of industry knowledge, combined with cost concerns, poses barriers to broader acceptance and utilization of sapphire in new applications.

Future Trends of Sapphire glass

Market Growth and Demand

The future outlook for the sapphire glass market appears robust, driven by sustained demand across various sectors.

Notably, the consumer electronics industry remains a significant contributor to market growth, particularly in the Asia Pacific region, which accounted for 44% of the global sapphire glass market revenue in 2023.

Factors such as rising disposable incomes, rapid urbanization, and a growing middle class are intensifying the demand for high-end electronics that utilize sapphire glass for its superior optical clarity and durability.

Technological Advancements

Technological innovations are expected to further enhance the production efficiency and quality of sapphire glass.

Advanced manufacturing techniques are reducing downtime and production costs, allowing for greater economies of scale.

As production processes become more sophisticated, the accessibility and quality of sapphire glass are anticipated to improve significantly, thus attracting new applications beyond traditional consumer electronics.

Expansion into New Applications

Sapphire glass is finding increasing applications in diverse industries such as healthcare, aerospace, and automotive.

In healthcare, its high thermal resistance and durability have positioned sapphire glass as a preferred material in over 50% of advanced medical imaging devices and surgical instruments.

The automotive sector is also adopting sapphire glass for use in lighting solutions and dashboard displays, forecasting a 15% increase in adoption in the coming years.

This diversification is likely to expand market opportunities and attract investments in research and development.

Sustainability Considerations

As the market evolves, sustainability will become a critical factor influencing manufacturing practices.

Environmental protection measures are likely to be integrated into sapphire glass production processes, addressing growing consumer and regulatory demands for sustainable materials.

The emphasis on eco-friendly practices will not only enhance the industry’s reputation but also align with global trends toward sustainability in materials science.

HY offers a range of OEM custom sapphire glass solutions tailored to your specific needs.

Contact us to learn more about how we can provide the ideal custom sapphire glass solution for your industry-leading products.

Email: wendy@hylasercutting.com

Tel & WhatsApp: +86 135 7058 6244