The manufacturing of sapphire domes is a specialized process integral to a variety of high-performance applications, particularly in the aerospace, defense, and medical sectors.

Renowned for their superior optical clarity, scratch resistance, and thermal stability, sapphire domes are essential components in devices ranging from missile systems to high-end consumer electronics.

The production process involves meticulous steps that include raw material selection, precision machining, polishing, and rigorous quality control, ensuring the domes meet stringent industry standards for performance and durability.

Key manufacturers in the sapphire dome market include industry leaders such as Rubicon Technology Inc., KYOCERA Corporation, Saint-Gobain, and SCHOTT AG.

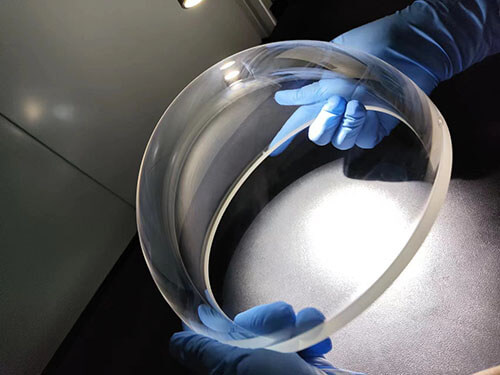

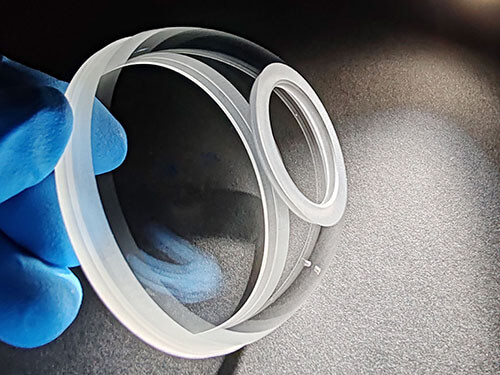

In China, HY is a leader in the custom sapphire domes industry, supplying high-quality precision custom-made sapphire domes at very competitive prices. The diameter of HY custom sapphire domes can be manufactured up to Φ390mm.

What’s more, HY can produce a variety of custom sapphire domes, including sapphire hemispherical domes, sapphire hyper-hemispherical domes, kerfs sapphire domes, spherical sapphire domes, aspheric sapphire domes, sapphire domes (Sapphire fairing radome), U-shape sapphire domes, conformal sapphire domes, and special–shaped sapphire hyper-hemisphere dome.

These companies leverage advanced manufacturing techniques to innovate and optimize production efficiency, which is crucial given the growing demand across various sectors. The Asia-Pacific region, in particular, is a dominant player in the market, driven by technological advancements in consumer electronics and a robust manufacturing infrastructure.

Furthermore, the market’s expansion is accompanied by competitive dynamics, including strategic collaborations among manufacturers aimed at enhancing innovation and market reach.

Overall, the sapphire dome manufacturing sector exemplifies the intersection of advanced material science and growing market demands, positioning it as a critical area of focus in both technological and environmental discussions.

Manufacturing Process Of Sapphire Dome

The manufacturing process for sapphire domes involves a series of intricate and precise steps to ensure high-quality products suitable for various applications, including aerospace and scientific research. The process begins with the selection of high-grade raw materials, which are essential for producing industrial sapphire products.

Raw Material Selection and Initial Processing

Once the appropriate sapphire raw materials are selected, they are shaped and cut into the desired form. This step is critical as it sets the foundation for the final product. Following this, the sapphire is subjected to high temperatures to facilitate molecular bonding, enhancing the durability and stability of the material.

Precision Machining

After initial processing, the sapphire undergoes precise mechanical processing, which includes advanced CNC machining. This technology enables manufacturers to achieve intricate cuts with exceptional quality and accuracy, often within tolerances of +/-0.02 to 0.1 mm. Such precision is particularly important for applications that require exact dimensions and high optical clarity, especially in extreme conditions such as deep-sea exploration and extreme temperature measurements.

Polishing and Quality Control Of Sapphire Dome

The final stage of the manufacturing process involves polishing the sapphire to achieve a smooth surface and optimal optical properties. This polishing is vital for ensuring that the sapphire dome meets stringent visual and functional specifications.

To maintain high quality throughout the manufacturing process, rigorous quality checks are performed at every stage. This includes real-time inspections using advanced metrology tools to assess dimensional accuracy and surface finish.

Final Inspections and Packaging Of Sapphire Dome

Before shipment, each sapphire dome undergoes a comprehensive final inspection. This inspection evaluates optical clarity, dimensional accuracy, and scratch resistance, ensuring that only products that meet the highest standards are delivered.

Furthermore, careful packaging and labeling processes are implemented to protect the products during transit and to provide important information about the parts.

By adhering to these meticulous manufacturing processes, companies like Meller Optics, Inc. and HY Optics ensure that their sapphire domes are not only durable and high-performing but also suitable for a diverse range of demanding industrial applications.

Key Manufacturers Of sapphire dome

The sapphire dome market is characterized by a mix of established companies and emerging players who contribute to its growth through innovation and quality manufacturing. Major players in the industry include Rubicon Technology Inc., KYOCERA Corporation, Saint-Gobain, SCHOTT AG, And HY Optics.

All are recognized for their significant contributions to sapphire manufacturing technologies and applications in various sectors, particularly aerospace and defense, consumer electronics, and medical devices.

Major Companies

Established Leaders

Rubicon Technology Inc.: Known for its advanced sapphire crystal growth techniques, Rubicon plays a critical role in the supply chain for sapphire products.

KYOCERA Corporation: A global leader in ceramics and sapphire manufacturing, KYOCERA supplies materials for a range of applications including electronics and optics.

Saint-Gobain: This multinational company specializes in high-performance materials, including synthetic sapphire, used in demanding applications like aerospace.

SCHOTT AG: With expertise in glass and glass ceramics, SCHOTT also produces sapphire components that are vital for optical and electronic applications.

Emerging Players

Several newer companies are entering the market, leveraging innovative techniques to enhance production efficiency and product quality. Companies like Crystalwise Technology Inc., Iljin Display Co., and Juropol Sp. z o.o. are becoming notable contributors to the market, focusing on advanced manufacturing processes and expanding product applications.

HY is a leading manufacturer in China specializing in custom sapphire domes, offering high-precision, tailor-made sapphire domes at highly competitive prices. HY is capable of producing sapphire domes with diameters as large as Φ390mm. In addition, they offer a wide range of custom sapphire dome designs, including hemispherical, hyper-hemispherical, kerfs, spherical, aspheric, fairing radomes, U-shaped, conformal, and specially shaped sapphire hyper-hemispherical domes.

Geographical Distribution

The Asia-Pacific region dominates the sapphire dome market, driven by the rapid growth of the electronics and medical industries. Countries such as China, Japan, and South Korea are at the forefront, benefiting from their robust manufacturing infrastructures and technological advancements.

Additionally, regions like the Middle East are beginning to make their mark, particularly countries such as Israel and Saudi Arabia, which are investing in sapphire production technologies.

Industry Dynamics

The competitive landscape of the sapphire dome market is shaped by continuous research and development efforts aimed at improving production processes, crystal quality, and cost efficiency.

This dynamic environment encourages collaboration and strategic partnerships among manufacturers to enhance market reach and technological capabilities.

Applications of Sapphire Domes

Sapphire domes are utilized across various industries due to their unique properties, which include high optical clarity, scratch resistance, chemical resistance, and thermal stability.

These features make them suitable for a wide range of applications.

Aerospace and Defense

In the aerospace sector, sapphire domes are critical components in missile systems and fighter jet cockpit canopies. Their high-pressure resistance and durability allow them to withstand the rigors of high-speed air friction and harsh environmental conditions.

Moreover, they are used in infrared sensor protection covers, providing exceptional visibility while safeguarding sensitive equipment. The increasing global defense budgets and modernization efforts further drive the demand for sapphire domes in these applications.

Optical and Imaging Systems

Sapphire domes are prominently used in optical systems, such as camera lenses, periscopes, and underwater observation devices. Their ability to transmit visible and near-infrared light makes them ideal for providing a clear field of view while protecting internal components from damage in harsh environments.

In aerospace applications, sapphire domes serve as camera lens protectors, shielding against cosmic radiation and micrometeoroid impacts, ensuring reliable operation in extreme conditions.

Medical Devices

Sapphire domes also find applications in the medical field, where they are used in devices such as endoscopes and surgical instruments.

Their biocompatibility and ease of disinfection make them suitable for providing clear visuals while maintaining safety in medical procedures.

Industrial Applications

In industrial settings, sapphire domes protect sensors and cameras from extreme conditions, including high temperatures, high pressures, and corrosive environments.

Their robust nature makes them an ideal choice for equipment operating under demanding circumstances.

Consumer Electronics

The consumer electronics industry increasingly employs sapphire domes for their durability and scratch resistance, particularly in high-end smartphones and smartwatches. These devices benefit from the material’s exceptional hardness, providing a protective cover that enhances product longevity and performance.

The trend towards energy-efficient lighting has also seen sapphire domes utilized in LED technology, driven by their suitability for manufacturing LED substrates and components.

Environmental Monitoring

Additionally, sapphire domes are valuable in environmental monitoring applications, where their chemical resistance allows them to be used in various scientific instruments.

They are ideal for extreme conditions, such as deep-sea exploration, where stable performance is crucial.

Comparison to Other Materials

Sapphire glass exhibit superior characteristics compared to traditional optical materials such as glass, fused silica, and quartz.

One of the most significant advantages of sapphire is its exceptional mechanical strength and durability. Sapphire windows are renowned for their hardness, ranking second only to diamond on the Mohs scale, which confers remarkable scratch resistance and makes them ideal for use in harsh environments, including aerospace, deep-sea applications, and defense systems.

In contrast, traditional materials like glass and fused silica are more susceptible to scratching and shattering, limiting their applicability in high-stress situations. While quartz and fused silica offer moderate durability, they do not match the resilience of sapphire under extreme conditions, rendering sapphire a valuable solution for industries that require long-lasting optical performance.

Additionally, sapphire demonstrates high optical transparency across a wide wavelength range, including ultraviolet (UV), visible, and infrared (IR) spectra, making it suitable for multispectral devices such as thermal cameras and infrared imaging systems.

This wide transmission spectrum further enhances its utility over conventional optical materials, which may have more limited transparency and durability profiles.

Thermal performance is another area where sapphire outshines its counterparts. Unlike many ceramics and glass materials that can weaken significantly under thermal stress, it maintains structural integrity and optical clarity even at elevated temperatures.

The tensile strength of sapphire remains relatively constant from room temperature up to 800 degrees Celsius, while its compressive strength along the c-axis decreases dramatically under similar conditions, highlighting its temperature-dependent reliability.

Market Trends Of sapphire dome

The sapphire dome market is currently experiencing significant growth, driven by various technological advancements and increasing demand for high-tech applications.

The market is characterized by a robust upward trend, with a projected compound annual growth rate (CAGR) of approximately 6% from 2023 to 2030.

This growth is largely attributed to the rising production of consumer electronics and LEDs, which require durable materials such as synthetic sapphire for their manufacturing processes.

Regional Dynamics

Geographically, the Asia-Pacific region leads the market due to its strong manufacturing base and heightened consumer demand.

Key countries such as China, Japan, and South Korea are pivotal in the production of synthetic sapphire, largely driven by the burgeoning consumer electronics sector and the medical industry. The region’s rapid construction activities and infrastructural developments further stimulate the demand for optical components like sapphire domes, enhancing market growth prospects.

In contrast, North America and Europe also represent substantial market shares, supported by their advanced aerospace, and defense sectors, and high demand for consumer electronics.

The competitive landscape features major players such as Crystalwise Technology Inc., Iljin Display Co., Juropol Sp. ZOO, and HY which is actively engaged in product differentiation and innovation to capture greater market share.

Emerging Applications and Innovations

The sapphire dome market is poised for further expansion as emerging technologies such as 5G, IoT, and quantum computing present new applications for synthetic sapphire. Continuous innovation in crystal growth techniques and enhancements in material properties are essential for companies aiming to maintain competitiveness in this evolving landscape.

Future Trends Of sapphire dome

The future of the Sapphire Dome market is expected to be characterized by substantial growth driven by technological advancements and evolving consumer demands.

Technological Advancements

Continued innovations in crystal growth techniques and material properties are vital for maintaining competitive advantages within the Sapphire Dome industry.

As manufacturing processes improve, there will be an increase in the production efficiency and quality of sapphire products, making them more appealing across various applications, particularly in the electronics and defense sectors.

The integration of emerging technologies such as 5G, the Internet of Things (IoT), and quantum computing is anticipated to further stimulate demand for sapphire materials.

Sustainability Focus

The growing emphasis on sustainability and environmentally friendly practices is likely to enhance the appeal of Sapphire Dome products, aligning with global movements toward greener alternatives.

This shift is expected to drive the demand for sustainable manufacturing processes and recycling initiatives, which could reshape industry standards and consumer expectations.

Market Expansion

Emerging markets, particularly in the Asia-Pacific and Latin American regions, present significant opportunities for growth as economic development and infrastructure projects ramp up.

The expansion of the electronics industry within these regions, fueled by advancements in technology and rising disposable incomes, is likely to further bolster the Sapphire Dome market.

Strategic Collaborations

Strategic partnerships and collaborations among key industry players are anticipated to foster innovation and improve market penetration.

Such alliances could facilitate the sharing of resources, technological advancements, and market insights, thereby enhancing competitive positioning.

Industry Dynamics

As the market continues to evolve, an increase in mergers and acquisitions among major players is likely to be observed.

This trend will lead to enhanced production capabilities and more efficient distribution networks, enabling companies to better meet the rising global demand for Sapphire Dome products.

HY offers a range of OEM custom sapphire dome solutions tailored to your specific needs.

Contact us to learn more about how we can provide the precision optical sapphire dome for your industry-leading products.

Email: wendy@hylasercutting.com

Tel & WhatsApp: +86 135 7058 6244